Everything posted by Zed Head

-

Front brakes locking up

I kind of forgot about the booster, in between. The other way to check the rod is to loosen it until the clevis pin rattles. Forgot that method, if it's already together. Easier. Still wondering, what initiated the problem? You never said.

-

Front brakes locking up

I know there's a procedure in the FSM, but the one essential thing to look for is that the MC rod does not have any tension on it with the pedal up. My method is to adjust the pedal to where to where I like it, then adjust the clevis on the rod to where the clevis pin will slide in easily without moving either the pedal or the MC rod. That will place the MC piston at its proper position in the MC and the pedal where you want it. You can fine tune from there to take up some small amount of play before the MC piston moves, but it won't take much before you're blocking that hole. You can adjust the clevis by turning the rod, inside the MC. It's not attached to anything, it will spin easily. So leave the clevis over the pedal hole, and turn the rod until the clevis pin slides in. Then maybe a bit more to take up any play. I use a pair of pliers, or long nose vice grips to turn the rod. It's cramped up there. You almost can't go wrong this way, I think. If your problem came from nowhere though you probably have something else going on. Did you change something recently?

-

Front brakes locking up

Similar topic just came up. The MC rod is adjustable. What can happen if it's too long I described in Post #15. http://www.classiczcars.com/topic/51812-brake-booster-check-valve-question/

-

Project Crush

That's a lot of oil. One quart / 100 miles. The F54 flattop/N47 is a non-factory combination. Higher CR, but it also means the PO had the head off. Was it supposed to be a rebuild or just totally unknown? Cylinder pressure only shows sealing ring quality, not oil scrapers. Is the PCV system working? No chance that you have a blockage, allowing crankcase pressure to build up? You might check the cam chain for wear, and look for other signs, just to get an idea of if it's an old tired short-block, or a re-ring that might wear in (unlikely,but it's a hope.).

-

ZCON 2015 Hookup

Thanks for the compliments, I didn't realize my imaginary internet persona creation was so strong. No though, unfortunately, I mis-wrote, and I was just referring to the thread. Not ready to destroy my illusion yet by becoming real! I'm in Oregon, thinking about replacing my rear main seal. My leak-free engine is slightly leaky. Looks like a big show this year, I don't remember seeing so much about it in the past. Don't over-do.

-

ZCON 2015 Hookup

I was afraid to look. But everybody's here now so I had to take a chance.

-

ZCON 2015 Hookup

Just realized this wasn't a singles dating thread... Thanks for those pictures on the fiddlingwithzcars site. Can't wait for the captions, all 168 of them (or more).

-

Project Boondoggle (or, so I went and bought a Z!)

You've already done all of the hard work. Carve that torn section off and use it. If it starts to degrade you can pop the pin out, drop the casting, and insert a new one, probably without removing any brake lines or strut mount bolts.

-

Swapping cams one engine to another

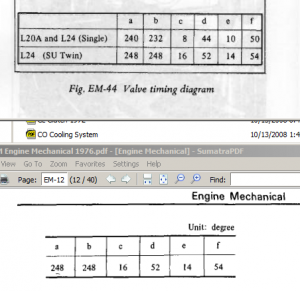

My stock engine sounded cammy when it was running rich. Numbers-wise, the 280Z A grind, is the same as the early 240Z L24 grind. Made a picture of 72 and 76 numbers. And I don't know that I would worry about the marks on the cam. Looks like it may have had some rust on it that wore off, but hard to tell if it's going bad. Don't see anything significant. Cam changes can be a whole giant can of worms. The cam numbers are shown in site's atlanticz link also. I like to go to the source when I can.

-

Rethinking the Analog EFI

Gasoline quality has drifted also. The gas sold today, even without ethanol, is probably different from what was available in the 70's. As engine management advances to handle more fuel variation, which makes a more dependable car, the fuel suppliers can get looser with their specs., which saves them money.

-

Poor Gas Mileage - '77 280Z

"Speedometer" was probably meant to be odometer. You can check your odometer using mile markers on the freeway. They wanted you to check spark plugs because they can indicate how rich the fuel-air mixture is by color and carbon buildup. The smell of the exhaust is also a clue. Does it smell gassy? My 76 suddenly started getting terrible mileage when the fuel pressure regulator (FPR) went bad. Check fuel pressure if you can. It's very important. And you can get a good idea of the quality of the coolant temperature sensor circuit by measuring resistance at the ECU and comparing it to the temperature chart in the FSM. You have a lot of "should"s and "should be"s in your post. You have to get numbers and take a close look to really know. All of your shoulds say you should be getting better mileage. So they must not be what they should be.

-

Swapping cams one engine to another

The aftermarket guys tend to mark their cams. Check the back of the last cam tower. Also, if it's a regrind the base circle will be smaller. The part of the cam lobe that has no lift will be thinner, compared to a stock cam lobe. It is said that you can swap the complete assembly of cam towers, cam and rocker arms from head to head, by carefully adjusting the cam towers before torquing them down. It's not a factory recommended procedure though, just something that has worked in the past. Are you sure the cam is worn and burned. The base circle of each lobe sees essentially no pressure. Only the force of the anti-rattle springs. Post a picture.

-

Brake Booster Check Valve Question

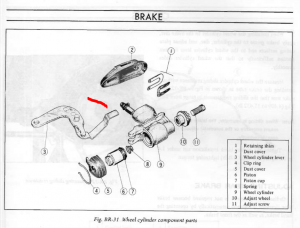

I think that it might be possible for the self-adjusting mechanism to over-turn the wheel in the adjuster. I've studied it and the little arm that grabs a tooth and moves it is meant to have a certain limited travel. So that it can only grab the next tooth after certain amount of wear allows the lever's starting point to drop back to the next tooth. And the width of the arm causes it to ride on top of the teeth until the proper moment arrives. For many brake lever pulls the adjusting arm just slides back and forth on top of the adjusting wheel teeth. Until, finally, it can drop down, grab a tooth, and move it forward. Considering the beating that brakes take when we replace the shoes it wouldn't be a surprise to find that arm malformed or worn. Could also be that the external stop, or bumper, that determines the starting position of the external portion of the brake lever, is allowing it to drop back too far, allowing it to grab a tooth early and move it too far.

-

L24 Rebuild -Again!

Thought you were supposed to hold RPM at 2000 for 20 minutes with a new cam to get those surfaces mated with good oil supply.

-

Brake Booster Check Valve Question

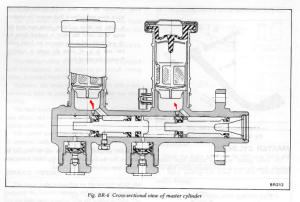

Just for fun, and a reason to study one of these excellent Nissan drawings. As I understand things, it's possible to adjust the MC rod so far forward that the return hole to the reservoir, which also releases pressure, is never opened. Brakes are bled cold, fluid heats up and expands, the pads and shoes are moved, car is slowed. I highlighted the two holes that can get covered. Never had it happen to me but it seems feasible and has been reported. You can see how the piston seals are right next to the holes, so that pressure is created as soon as the pistons move.

- 1976 280Z Restoration Project

-

Brake Booster Check Valve Question

beerman's test is good for the closed reservoir hole I was talking about in Post #2. I know you only asked about the check valve so maybe you're on your own problem-solving path. But you mentioned the brakes being stuck after sitting for 3 days in Post#3, implying that they were frozen after sitting, but now on the last half mile of a test drive. Implying that they weren't stuck when you started the test drive. beerman's test is for a hydraulic lock in the system. Rust and pins are mechanical. I don't see how a collapsed line can hold pressure, unless it was crimped tight, but who knows.

-

Brake Booster Check Valve Question

Of course, have to ask, are you sure it's the front pads on the rotors? I've noticed that my rotors (or discs - why do we call them disc brakes but talk about rotors?) get rusty pretty quickly. Some surface rust on pads that haven't retracted much could cause sticking, I'd guess. The piston seals are supposed to pull the pistons back, giving the pads some space, as they return to where they were stretched from. The elasticity of the seal material is important. Old or heat-baked seals might lose that quality. I'm also pretty sure that my rear drums rust up quickly too. I always get a light grind when I first apply the brakes after the car sits a few days. Seems to come from the drums though, smooths out right away.

-

Servo diaphgram and control valve for AC on a 240z

Have fun C'man - http://www.classiczcars.com/topic/49754-throttle-opener-control-valve-and-servo-diaphragm-for-a-240z/

-

Servo diaphgram and control valve for AC on a 240z

Get one from a 280Z. They come stock from the factory. You'll have to fabricate a bracket by your throttle linkage and wire up a solenoid valve and vacuum tank.

-

Rethinking the Analog EFI

I ponder how to make a 90's era system work on my car. Waiting for my Pathfinder to break so I can cannibalize it.

-

Brake Booster Check Valve Question

The FSM says to put about 20 inches on it to test leak-down. But I can't see how a bad valve would cause sticking. What kind of sticking? Side-to-side or stuck on? People have over-adjusted their master cylinder rods and closed the return hole to the reservoir. As the fluid heats up and expands the brakes get applied.

-

L24 Rebuild -Again!

Monroe's How To Rebuild book says .020" is the most you can shave before needing cam tower shims. Can't remember standard head thickness so can't do the math for minimum.

-

Bleeding rear brakes

That makes it easy. I've found on the fronts though, that the remans can have the bleed screw hole bored out and rethreaded and a different size bleed screw installed. Just my experience. I never got speed bleeders for the front but did notice the difference when I replaced only one caliper. Which led to unbalanced braking, but that's another story.

-

map light / dome light issue

Referring to Kurbycar32's comment. The switch at the map light itself. If you want to test the wiring supplying power, take a light bulb and attach a wire from the positive feed to one electrode and ground the other. Easiest with a spare light bulb fixture.