Everything posted by Zed Head

-

Got Bored So....

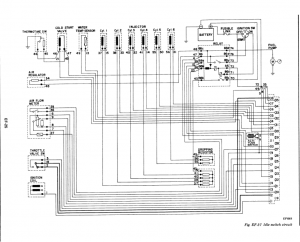

If they do a load test,which I think they do in CA, you'll end up screwed up. The system is designed so that idle fuel is a whole separate function from driving (loaded) fuel. That's why there's an idle switch in the TPS and an idle air bypass screw on the AFM. You'll probably pass idle, but fail 2500 RPM.

-

Bouncing MPH?

Could be that one of the ends is not seated correctly, probably the transmission end. I've found that there's enough play in the sheath to get the fitting partially tightened and have that happen. Take the transmission fitting off, pull the cable out partway, and insert it into the transmission. Then slowly tighten the fitting while rotating the propeller shaft. That way you'll know the trans. end is in, and the odds are good that the speedo end will slip in like it should.

-

Got Bored So....

One easy small step up in usable power is the exhaust system, apparently. Shouldn't affect emissions negatively. If you have a catalytic converter, there might be better flowing newer options out there than the stock unit. Slightly bigger pipes, new cat, better muffler.

-

Gm's Business Logic

This isn't about ignition switches or anything causing bodily harm, just a view on how business people think. I had to read it twice to be sure I understood. The words, not the logic. This product's value is not drawing the consumer in. We need to make it worse. http://finance.yahoo.com/news/gm-cut-chevy-gmc-powertrain-warranty-60-000-143947688--finance.html

- L28 Rebuild? Swap? Leave Alone?

-

Got Bored So....

Looks great! So, of course, it's time to change things for more power! Seriously, it all looks good to me.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

I didn't actually see anything on my AFM contacts and it was a new one from MSA also. Out of nowhere it just quit. I got home, took the AFM out, checked the pins for continuity (none), took off the side cover and fiddled around with the contact surfaces, and it started working. I figured that a hair or something small and hard to see got stuck between the contact surfaces. But I didn't have all of the issues you had before I got the "ten seconds of running after Start", so I went directly to looking at the AFM contact switch. Good luck. The worry will fade away eventually. With these cars there's always something else anyway. I have my favorite tow shop's number in my cellphone.

- 77 Z Drives For About 10 To 15 Minutes,then Dies.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

It's the directionality of the relay diagram that gets me. There's some backward loops in there. Anyway, back to crazy - the start-run for 10 seconds-then die is also a sign of a dirty AFM fuel pump contact switch. I had that happen to me but once it got dirty, it never fixed itself. I had to run power from the rear window defogger to get home. You can see the switch under the black cover of the AFM. Maybe yours was slowly losing contact and now it's totally open. The Start signal runs the pump, the engine starts,and only runs until fuel pressure drops. You can clean the contact with a match book striker. You'll see a tiny spark with the key On when it opens and closes if it's working. It's also another way to test the pump circuit. Take the cover off and rotate the weight and you'll see the lever that opens and closes the switch.

- L28 Rebuild? Swap? Leave Alone?

- 77 Z Drives For About 10 To 15 Minutes,then Dies.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

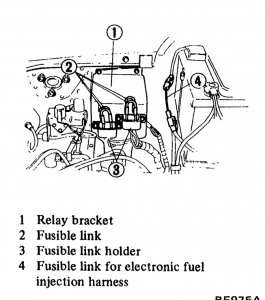

I was thinking more of dirty connections, not a melted link. I mentioned early on in this thread about someone with a fuse, hidden in the trunk, that would open the connection when it got hot, then close and mysteriously fix itself when it cooled. It's apparently a BMW problem that has happened to more than one person, but is not common. The fuse is in a moist spot and after 25+ years the corrosion builds up. He might fix the problem with just a wiggle of those connections.

- 77 Z Drives For About 10 To 15 Minutes,then Dies.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

I'm still back on "engine dies tach goes to zero". You're right though, I did not delve in to the details, I'm just posting things that might help. Plus, I can't really figure out how exactly that combined relay works. Is there not a diode between Pins 36 and 39? It connects the two relays somehow, but what does it do? No offense to crazy but the wiring diagram and the information you posted are in the same chapter as the tests he's run. The trees and forest thing. Maybe the fusible link you mentioned is the one overheating. Check 'em all.

-

L28 Rebuild? Swap? Leave Alone?

Your chain guides actually look in really good shape. The used ones I've seen all have grooves worn in them from the links rubbing. The damper pulley looks like a problem. I don't know if Nissan put zero at the same spot on both styles or started from scratch with each design. I think that you could get a 240Z pointer and be right, assuming the damper is in good shape. But it's always good to confirm the TDC mark is correct.

-

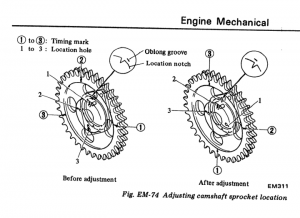

Timing Chain Rotation To Hole #3

I think I had my befores and afters backward in my other comment. Looks like you're at after-after now so should accomplish your objective well.

- 77 Z Drives For About 10 To 15 Minutes,then Dies.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

The EFI relay has its own fusible link(s), inline from a wire connected directly to the battery positive post. The link has its own blade type connectors. Green wire. There might be two, side by side, some time between 1976 and 1978 they added one. That might be your problem, they are in a dirty, corrosive spot by the battery fumes. Follow the wires connected to the battery positive post and you'll find it. You might be on to something.

-

L28 Rebuild? Swap? Leave Alone?

I don't think that you'll get good pressure numbers from an engine that's been sitting, turning it with that gear reduction starter. Some other things you might examine are the backs of the valves, for carbon deposits, and the tops of the pistons, what you can see through the plug holes. If they're all crusty and caked, the engine has some miles on it, if they're shiny and look good, maybe somebody just put it back together and ran it for a few miles. Look at the chain guides from the top, see how much plastic is left. High mile engines will wear the guides down. Check the notch and groove for alignment and hole number, that will give an idea of chain wear. The valve train area looks pretty clean, no signs of sludge. That's a sign.

-

Timing Chain Rotation To Hole #3

There's always some slack in the chain, but when the engine is running, it's all on the passenger side, taken up by the tensioner. You just moved the slack to the driver's side when you did your adjustment. If the sprocket is on, you can remove the wedge and turn the sprocket backward to find out where the notch really ends up. It's not where it will be when the driver's side is tight. It's going to be even farther to the left. Looks like #3 might be too much, to me. The driver's side of the chain needs to be tight when you look at the notch and groove.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

site makes a good point. I think Nissan changed from the AFM to the oil pump/alternator switches in mid or late 77. Which EFI relay do you have, the big silver 1x1x2 combined EFI/pump one or the smaller one? Note - in past posts I think I've said that I had a 78 with the older EFI/pump relay. But I was confusing ti with AFM's. I had a 78 with an AFM that had the switches, but not used. But the 78 pump relay was separate from the EFI relay.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

Be careful on interpreting "continuity". For some reason, Nissan broke the testing up in to continuity and real numbers. That 180 ohm number looks like the right number for one of the circuits on the AFM. 180 is small compared to thousands. The real numbers are shown later in the FSM chapter, where removing and testing is described. The air sensor reading is close. Wouldn't cause a no start condition. It's great that you're digging in to the details of all of the tests but you're skipping over the basics, like "is there fuel" and "is there spark". With all of your test numbers, and the answer to those two questions, you can then step back and look at the complete picture. I think you might be buried in trees right now.

-

Valve Adjustment.

I've pondered and commented on this before. I had the same thoughts. My guess is that Nissan went to recommending hot because most engines are hot when mechanics work on them. It's actually riskier hot, because the lash gets tighter when the engine cools. So if you're too tight hot, but still have some lash, you could burn a valve when starting cold. In theory, all of the metal of the individual valves expands at the same rate. so proper cold lash will equal proper hot lash. Cold should be the best way to do it. But hot seems to be a rite-of-passage, like changing a spindle pin.

-

L28 Rebuild? Swap? Leave Alone?

You could have surface rust in the cylinders also, hindering sealing. I was thinking that a spin would reveal any clanking or crunching, not really useful for a compression test on an old cold engine. Plus that looks like newer reduction geared starter, they turn slow. Did you prop the carbs open? That can affect pressure readings. Makes it harder to draw air in. Also, you have a picture of the notch and groove but the damper marks aren't at zero. And which block is it, N42 or F54? Won't tell you for sure, but if it's F54 the PO might have left the flat-top pistons in (assuming it's an NA F54). That would raise the CR. And, that looks like an L24 damper (multiple timing marks) with an L28 timing tab. So the damper's not stock. And it has a mechanical fuel pump, not stock for a US market L28. You're going to take it apart anyway, I can tell. Just a few things to think about.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

Sounds like a corroded contact point, or bad ECU component. Too bad you're not a hoarder yet, you'd have a spare ECU to try out. Another thought on diagnostics - light bulbs in parallel on suspect circuits. If the light goes off, that's a sign. On the positive side - you only have to wait 10 to 15 seconds before you can try something new. 20-25 seconds round trip. You can check everything in one hour.