Everything posted by Zed Head

- 77 Z Drives For About 10 To 15 Minutes,then Dies.

-

Manual Transmission Oil. What's Best?

The Datsun transmissions seem to do very well with Redline's MT-90 oil. Better than a generic 90 wt., for sure, with a transmission that has some miles on it.

-

1976 280Z Restoration Project

Sorry I missed this. Yes, it should if the 3.9 came from a 280ZX NA engine. The turbo cars with the "Borg Warner" transmission, used the 300ZX bolt pattern I believe, which won't work, but the NA pattern will. The spline pattern and size of the slip yoke (the part that fits the trans.) is the same for all NA transmissions, way up in to the 1990 cars (71C transmissions).. As I said, I have both a square and round flange differential in my garage. One 1976, one 1978. I've had them both in my car with the same driveshaft.

-

Injector Leaking.

I searched Google the other day for "polystyrene and gasoline" and that's what comes up. Not the redneck part but the rest. Pretty sure I'm on a list now. We're all on it.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

You could hook up a meter and run it through its paces but the tach is a meter and driving is a good load test. The problem with testing them is that they tend to fail under usage, when heat builds up internally, so they'll test fine but still fail when they get hot, just from current passing through the transistor. Looks like 77 stopped using dual pickups so either the GM HEI module or a complete ZX distributor swap would work for you. You might examine your distributor first and see what shape it's in. If the breaker plate bearings and holder are toaste (common), or there's slop in the shaft (eyeball the reluctor/pickup gap) then a ZX dist. swap might be the best bang for the dollar. Otherwise, the HEI swap is cheap and effective, but takes a little bit more wiring work.

-

Injector Leaking.

Cups with polystyrene blends might hold up fine. Pour a little in and see. I was just offering some advice to avoid a melted mess of plastic gasoline on top of your engine if you got the wrong cups.

-

Need Help With Timing!

You should call him so that he can make things right for the next guy.

-

Msd 6Al Wiring Help Please.

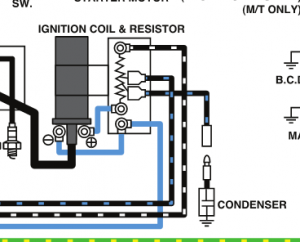

All Z's should have those wires at the ballast resistor location. Here's an example for 1976. One is black with white stripe, the other is back with blue. Your year may have different colors.

-

Shock Tower Brace

On the back, running a brace from each tower up the roof might offer the benefits of a roll cage. You can go nuts thinking of all the places that might be braced better. Some one on another forum even noted that their car had better, stiffer handling, when they glued the windhshield in. And there are some that say the car gets flimsy when the floor panels are removed, implying that much load is handled there, they're not inert. So bracing the floor panel somehow should help. And rusty floor panels would be bad.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

Sometimes the tachometer needle starts acting weird when the module is going bad, also. And the needle will go to zero right away if spark stops and you're coasting in gear, whereas it will still show RPM if you're coasting in gear and it's a fuel problem. Just a clue to look for while you're in the driver's seat.

-

Injector Leaking.

Coke bottles work well too. Be careful on the cups, polystyrene will dissolve (edited from melt) in gasoline. Best test first. I had issues with the first set of injectors on my car also. They were mismatched brands, and a couple looked well-worn, so I just replaced them with new.

-

Need Help With Timing!

Make sure that you're actually on the compression/firing stroke before you go too far. Mistakes happen, but it would be a surprise if Rebello made one. Your TDC marks will align two times per cycle, once on the firing stroke and once on the exhaust stroke. The distributor will show 180 off like yours, on the exhaust stroke.

-

Need Help With Timing!

Since it's exactly 180 degrees off, the wire swapping should work fine, except that the length of the wires may be tight on some terminals. Curious - Did Rebello install the pump and quill? Mistakes happen.

-

Injector Leaking.

You could run any jumper wire from the coil center terminal directly to ground. No need for a spark to happen, the ECU will still gets its on-off signal from current flow. I agree it's a good way to protect the module, I'm pretty sure I damaged one of my own by leaving two plug wires off after doing some work one day. Don't know if it was the lack of a path or a stray spark but the module definitely was weaker afterward. Had to replace it.

-

Need Help With Timing!

Looks like your moon halves are swapped. Little for big. I think that means you could move your plug wires ahead three holes each and be on track, with a mystery for a future owner. Or you can drop the oil pump and relocate the shaft. Added a picture of mine from a fine-running engine at TDC on the firing stroke. Diseazd makes a good point about firing stroke. Cam lobes up on #1. Can't tell from your picture. Cam timing can also cause problems. If you take the valve cover off, check the notch and groove.

-

Injector Leaking.

You could wire it up and make the final power connection last. I make individual connector pins by pounding a piece of solid copper wire flat. Sticks right in there, converting female to male. Then I use alligator clips. Does take a little extra care though and can make you nervous. If you're just looking for leaks, then pressurizing the rail and injectors would work. If your FPR and pump check valve are working the rail will hold pressure and you only need to run the pump for second or two. I diagnosed a neighbor's injector with shop air. Even with a leak there was enough leftover fuel sitting in it to get pushed out. The body was cracked and it leaked externally. It was an old Porsche injector, that apparently is known for doing that and burning up cars.

-

Injector Leaking.

They would only spray at every third spark. And you probably don't want external sparks while you're spraying fuel, so messing with the coil and ignition would not be an option. Another way to do it would be to run a jumper to ground from every injector pin at the ECU connector. With the key on there should be power to the injectors, grounding them like the ECU would do should open them up. Run the grounds, turn the key on, the injectors open, open the AFM flap and the pump makes them spray. I have not tried this but it should work. Are you looking for spray pattern or do you want to measure output? Because the spray pattern of the stock Datsun injectors is essentially a thin stream. If you're using Bosch injectors, you'll get more of a mist. If you just want to check for leaks, then the AFM-flap method would run the pump and pressurize the rail.

-

Shock Tower Brace

Figuring out how the loads get distributed can be hard to do. Under lateral loads, like cornering, you could imagine that the highest loads are at the two inner attachment points of the control arm (transverse link in Datsun-speak), Which transfers in to the links that drop down from the body, and the diff mount/crossmember. The top of the strut only sees the weight of the car, essentially, as you describe, in-line. At first glance, it looks like the tops of the towers are important load-transfer points of a triangular structure. But because of the shocks and springs, and the flexible hinge at the hub, they really only see changes in "weight" of the car. It's interesting to look at because you can imagine a much weaker strut tube than is used. The double wall nature of the strut tube with a shock tube inside is really much stronger than it needs to be. So it leaves up-and-down as the force at the top of the tower, coming from the suspension. Which should really only be unusually high if you bottom out the shocks. So, in travelling over uneven bumps like a driveway entrance, you're probably really combating flex from twisting of the whole metal box/body. Which seems to me like it would a blend of fore and aft, and lateral, a diagonal flex. My 280 creaks the most when a front and rear wheel on opposite sides (diagonal) are unloaded at the same time. Like a driveway entrance. That's just one pass through the brain. Something new pops up every time I think about it.

-

Shock Tower Brace

This gets discussed quite a bit on various forums. To John C's point, the towers are already braced for lateral motion,under the vinyl. To Mark M's point, maybe bracing forward and backward (what a roll cage would do in addition to lateral) would be more helpful. Also, the 240Z is known to be flimsier than the 280Z so what helps on a 240 may not help so much on a 280. The use as a cargo barrier/holder though has obvious value. Maybe that's enough. It may also help in an accident, basically inert metal until needed. From what I've picked up, if I remember right, a triangular brace from the firewall to the front towers is the simplest bolt-on brace that you can add. It addresses fore and aft, and lateral, motion. Here's an example - http://www.racetep.com/zfront.html

-

Identifying 5 Speeds.1)

Did you mean 280ZX 3.9 long-nose? That's the typical diff for the 280ZX. The 300ZX NA's came with 3.7, typical, and have a different flange pattern. More work, to swap the flange so a 280Z or 240Z propeller shaft can be used.

-

Rear Engine Plate Difference.

My understanding is that the main difference, and maybe the only one, is that the bottom portion of the automatic plate is removable so that the torque converter bolts can be installed and torqued. The plate is actually just a dust and water shield so that makes sense.

-

Seat foam

They're called "hog-rings" and they're the stiff pieces of wire crimped around the edges of the material and the wires and the springs to hold everything in place. Search hog-ring on the net and you'll find a bunch. They were/are crimped in to the noses of hogs so that they can be controlled. Actually, (edit, I'd forgotten) so they don't root around. They make different sizes for different noses, from little piggies to big hogs. How to ring a pig's nose (noise alert!) -

-

Identifying 5 Speeds.1)

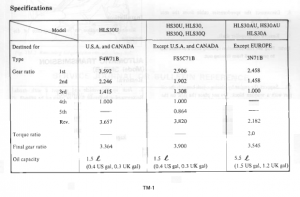

Actually, I was kind of lazy in my response. The ratios are listed for the 5 speed in the FSM. 5th is not direct. The "mysterious" 5 speed I was referring to is commonly called the direct-drive 5 speed dogleg "comp" box. Comp for competition. I think it was an option from Nissan at some time. Anyway, even if there was a list of codes for the transmissions, with the interchangeable parts you'd still have to do some calculations or open it up to know what you had. From the 1972 FSM. Note that the ratios do seem backward, compared to the ratios of the transmissions. The 5 speed needs the 3.9, and the 4 speed, the 3.36.

-

Identifying 5 Speeds.1)

Is this the mysterious "dogleg" 5 speed, that sometimes has a flange on the output shaft? 1:1 (direct) 5th gear?

-

Rocker Geometry Woes

Kameari has a solution to avoid the little click, but their product is a little pricey. A handy person could probably copy the concept to modify the stock parts. http://www.kameariusa.com/l6-adjustable-timing-chain-tensioner/