Everything posted by Zed Head

-

P90 With Dished Pistons (Yes, N/a)

According to Honsowetz (How to Modify...) the max valve lift for the stock valve springs is .460". The valve seals also have a limit, which requires either an "A" type seal (not 100% sure what that means, vague memory) or Ford valve seals. Can't remember the details on the seals. Anyway, it doesn't look like a drop-in, it will take a little extra research. You've changed the topic of the thread, but it looks like you're now planning a high lift cam with flat-top pistons. It would pay to verify valve clearance with the piston tops. There might be a problem there too.

-

Centerforce 2 Clutch Disk

I think it depends on how far you let things go before. Some people recommend just scuffing up the pressure plate and flywheel with sandpaper if there are no grooves or heat-check spots and the surfaces are still flat (checked with a good straight edge). Monroe describes it in his How To Rebuild book. AS for where to get them, RockAuto has a good selection, the auto parts stores still stock them, and Nissan dealers may still carry them also. After sanding the two metal surfaces, clean them well with brake cleaner. You'll need to know the size of the pressure plate and flywheel. But the disc itself fits the transmission shaft, so that's what matters, aside from friction surface size. I've sanded and cleaned a flywheel surface with no issues, using a pressure plate and disc kit. 30100-Y6800 http://www.courtesyparts.com/clutch-dis-p-329045.html (225 mm)

-

Alternator Wiring

http://iraggi-alternator.com/support/index.htm

-

1976 L28 Rebuild With P90 Solid Lifter Head

Most of the guys that have built engines will say that the slight bump in CR, and the headers won't improve performance much at all, on their own. The CR increase will make the engine more likely to knock, even with 94 octane (does Canada use the same octane rating as the US?). The stock exhaust manifolds are pretty good. The P90 head might flow a little more air than the other heads (the square unlined exhaust ports), but not much. The fuel rail and the injectors certainly won't do anything at all for performance. You'll need to find some injectors that match the stock injectors almost exactly or you'll screw up the ECU's fuel control. The aluminum Pallnet rail will probably help with the heat soak though, so that's an improvement. But you can do that with the barbed injectors. Most of the changes you're planning won't add much over stock, and will cost more money and complicate things. What are you hoping for? A rebuild with stock parts would probably get you the best running and most dependable engine, using the stock EFI system.

-

Alternator Wiring

You need to make the drawing match the alternator. Looks like someone wired a GM alternator for "one wire" operation. This link might be useful - http://www.hotrodlane.cc/ONLINETECH/CS130DREG.html Here's another - http://www.dynamo-bg.com/en/res/files/22/CS130en.pdf Can't find any "A" or "B" labels.

-

A Project Is Brewing...

Apparently those "horns" are for Noise-Vibration-Harshness (NVH) damping. If you have a ZX transmission you can use them. If you have an early transmission there's no holes for them.

-

$2.45 A Gallon In Alabama

211.9 cents/gallon for 89 octane in the Portland Metro area. And they fill the tank for you.

-

Just Did The Kia Hatch Seal

Someone, I think Tomohawk, asked a while ago about how many seals it takes to do a whole car. Looks like you used a front door seal (http://www.kiapartsnow.com/genuine/kia-wthstp-frt-door~0k01858760b.html) to do the hatch, is that right? So three door seals will do all three openings, but a person might not want the Kia Sportage hatch seal. I didn't think a door seal would be long enough for the hatch but looks like I was wrong.

-

L4 Water Pump On An L6?

I only have 280Z and 280ZX pulleys. I'll be keeping my eyes open in the wrecking yards in the future though.

-

L4 Water Pump On An L6?

There's a whole big thread on Hybridz about the LD pumps. Apparently, the original LD pumps pushed more coolant so people wanted them for their performance engines. But they don't make them anymore so the parts places are selling the gasoline pumps as LD pumps, or getting them mixed up. There are subtle differences in the pump body and blades. Some people ordered LD pumps and got gas pumps, some got LD pumps. And, for a while, the cast impeller pumps were hard to find,m apparently, only the stamped impellers were available. And they weren't very good. That's all I know. I'm always looking for easy part swaps though, so if a cheaper L4 pump will do the job with just a different pulley, that would be neat. The main reason I posted...

-

P90 With Dished Pistons (Yes, N/a)

It would run like a turbo L28, off-boost. Probably okay. 17% more displacement, and bigger valves, might make up for the lower CR. There are general formulas out there that try to estimate the benefit of increasing CR. Here's one - http://www.wallaceracing.com/hp-cr-chg.php Doesn't look like much loss. This is one of the basics of the argument people make that optimized ignition timing is far more important than a few extra CR points. The added displacement might actually increase power. The engine will sound a little dull though. The exhaust won't have that rippy sound that high CR and a performance cam tends to give.

-

L4 Water Pump On An L6?

That narrows it down. The LD28 pump is typically used by people that want more coolant flow. The cast impeller pumps are commonly available though for the typical L28. The LD thing confused me. Still not totally clear though, to me. I think that you're saying that the height of the water pumps are different, putting the pulley mounting flange closer/farther from the front of the engine. You didn't say specifically but it looks like you're assuming that the L$ pump impeller will fit the L28 timing cover and bolt up correctly, and the only issue is the pulley mounting flange offset. Anyway, looks interesting. If you supplied some measurements people could check their pulleys. Short answer, for me, is no I have not tried this. I do have some L28 pumps that I could measure though. As I said.

-

P90 With Dished Pistons (Yes, N/a)

There was a guy on the forum a while ago that put either a P79 or P90 head on a block with dished pistons. Said it ran fine, but it was his daughter's car and he was just getting it running so he could sell it. It was an EFI engine. Assuming the engine itself is in good shape, your biggest issue might be getting the SU's and intake mounted and the carbs tuned. I don't know if the P90 heads come with carb manifold mounting holes. I think that the other heads, N42, N47, for sure, and maybe P79, do, but they're designed for NA. The P90 is a turbo design, so no need for carb manifold holes. That's probably your decision-maker.

-

'90 240SX FS5W71C swap into '75 280z

Not a big deal in the big scheme but the later 240SX's did get the reverse synchro. It's shown in the Motortopia link above (copied specific below), and in the FSM's (baulk rings for 5th and reverse, 1996). Of course, Nissan kept the 240SX name but changed the platform from S13 to S14, so that's different. The Z31 71C's had some improvements also, like double synchro rings for 2nd gear, some years even had double rings for 2nd and 3rd. The cases are the same though, so the swap procedure works on any of them. Don't know about the Z32 versus Z31 stuff. People tend to call this a bellhousing swap but it's actually a front case swap. If you're from GM world, a bellhousing is completely separate from anything that holds gears and bearings. It is essentially an adapter for the trans and engine, and covers the clutch, flywheel and input shaft, In the procedure being discussed here, the part being swapped is precisely machined and contains the bulk of the gears and bearings. The "T5"'s use a separate bellhousing, I believe, but that's a completely different transmission and manufacturer. http://www.motortopia.com/cars/1973-datsun-240z-11118/car-pictures/240sx-transmission-swap-14041/IMG_2766JPG_Thumbnail1.jpg-412263

-

L4 Water Pump On An L6?

Are you trying to find an LD28 analog or a stock gasoline-powered L28 analog? You have the L4 pump, don't you have an L28 pump? I have an L28 pump to take measurements from. Not really clear what you're asking.

-

Driveshaft Freeplay

The noise from the transmission in neutral, that goes away when you press the pedal, is very common. All of mine have it. jmortensen posted in the past about helping someone change a bearing because of the noise, I think it was the countershaft bearing or maybe the mainshaft, and having a quiet transmission for only a short while. The noise came back. If we asked everybody on the forum to listen for the noise, we'd probably create a run a on bearings or rebuild kits. Ssshhhhh..... Wow, my first attempt to find that old post and it popped right up - http://www.classiczcars.com/topic/35592-throwout-bearing-noise/

-

Revs But Wont' Run......

Since the wiring is non-stock, it's not clear where the blk/wh was originally. A schematic of your car's wiring as it is now would help.

-

Revs But Wont' Run......

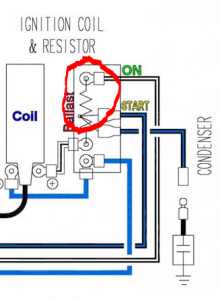

If the resistor has failed you'll get infinite resistance. No current flow allowed. A quick check would be to run a jumper wire between the two On and Start posts, or just move the On wire over to the Start post. It won't hurt anything for a short while, the coil will just get hotter if you leave it. If it runs that way, then you'll know the resistor wire is broken. Edit - not sure, since my ballast is gone, but you could probably bridge those posts with a screwdriver for a really quick check, if you have a helper.

-

Bcdd

The old trick of spraying starter fluid around potential vacuum leaks works very well on the BCDD. Of course, it has to happen on the "right" side of the click. If you're sucking in unmetered air, the starter fluid will find it.

-

6H bleeding brakes and still no luck

The pedal sinking to the floor is usually a sign of internal leakage in the master cylinder. But your second comment is a little bit confusing. If they feel good, what is the problem?

-

Bcdd

Woohoo, you get to use that funky connector with the rubber plug over it, up by the coil, that we've all wondered about. Could be the old corroded connections problem, or a partial-short across A and B at that connector if the rubber's gone. Or a gummed up solenoid. You might check the voltage at the single wire to the solenoid against ground while it's active to see what kind of voltage drop you're getting. I think a typical solenoid is about 1/3 volt. SteveJ probably knows for sure. Get as much easy information about the state-of-the-system as you can before tearing things apart.

-

Dash Gauge Illumination Problem

Somebody (SteveJ maybe?) has pointed out in the past that LEDs are polarity sensitive. You only show one LED application, but maybe you replaced a bunch. Or maybe you tested the speedo with one polarity but got the opposite when you reinstalled.

-

Bcdd

I wonder if your problem isn't actually somewhere else, like maybe at the speedometer. As I understand the BCDD system, it's supposed to be inactive under something like 10 mph. You shouldn't be hearing the BCDD clicking, with engine speed changes, at idle. The AC idle-up solenoid might do that though. The way the BCDD works and a pretty detailed test procedure are described in the Emissions chapter of the FSM. If you just have a blown diaphragm, somebody (one of the Captain's, if I remember right), took theirs apart and replaced the diaphragm with a piece of thin rubber. It's on here somewhere, they described it. But your problem doesn't sound like that.

-

Just Did The Honda Blower Motor Swap

Probably won't make anyone feel better, but after I fixed all of the leaks in to my cabin and got the inside well-dried (a nice hot summer), my back window fogging problems are dramatically reduced. It just takes a small seep to allow enough moisture in to fog things up. I had leaks up front and in the back. For while though, I had an auto parts store heater/blower/defogger mounted on a board, pointed at the window. and wired in to the defrost grid power. The circuit handled the load easily. Noisy and took some work to keep it from sliding around but it did the job. The other "fog" problem though was outside condensation on the cold hatch glass. Who's got the rear wiper modification they want to share?

-

Tdc With Slack On Chain

During manufacture, the spark plug ceramic portion is inserted in to the metal base then the lip of the metal is crimped over to hold the ceramic in and seal it. The hacksaw is used to cut off the crimped portion. Basically cutting off the top of the metal base, around the ceramic. Just place the blade in the corner at the base of the crimp and cut a thin ring of metal off. You have to work your way around bit by bit. You could probably also put the plug in a lathe or drill press and spin at low speed to cut a consistent cut. Don't let the saw get driven in to your gut though.