Everything posted by Zed Head

-

1969 HLS30-00182 on Ebay

The eBay seller has other cars for sale, including a GNose Z. If you search his phone number on Google you'll find his shop downn Califormia. It's a Google world we live in now. harmony01 | eBay Another "Collectors Dream!". Giant open cowl hood, but no giant motor. Maybe a past V8 car? Wide rear fender flairs also. Datsun Z Series 240Z G Nose | eBay

-

Steering issue

How about the TC rod? The wheel would move more forward and backward, rather than rotating, or both at the same time. Maybe you damaged a TC rod bushing or the rod is broken.

-

1969 HLS30-00182 on Ebay

The hood is a different color also. Not primer, but gray/silver with pinstripes. Looks like an accident. replacement parts purchased, and still being assembled. No mention of the bottom corner fender pieces and the center section either. Straight stories are hard to find with these old collectibles. The guy actually wrote the sentence below in the ad. "Body is straight with almost no rust and no collision damage that I can see. " Seems like when I ever see one of these I end up bashing the seller but they all seem to stretch the truth.

-

1969 HLS30-00182 on Ebay

-

1969 HLS30-00182 on Ebay

I sent the seller a question and he/she actually responded. Looks like a texter. "I don't see any pictures of the grill and lower front end. Is there damage there? " "no damage... grille and front bumper are in the car... Thx"

-

1969 HLS30-00182 on Ebay

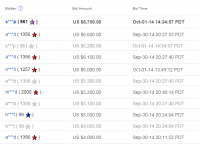

Any idea what it sold for?

-

1969 HLS30-00182 on Ebay

Good point. I just noticed that the eBay ad takes pains to not show the grill and front end of the car. Deceptive.

-

1969 HLS30-00182 on Ebay

I wonder if the guys that write the sales pitch for the eBay ad know how sleazy they sound, or if they just can't resist? The more exclamation points and capital letters, the more suspicious things look. "I am going to offer this car in as is condition one time..." then what? Hurry, hurry, hurry, one time only, get your Z car here, one time....

-

New to this forum! Does anybody have any Bilstein inserts for 240z?

Your getting deeper in to the morass. Here's one that people seem to like. The main difficulty is that there may be some trial and error involved to get it where you want it. People start high and work their way down. http://www.classiczcars.com/forums/suspension-steering-s30/48249-using-chevette-springs-re-gain-original-ride-height.html It looks like there may be some original spring stock still out there at the Nissan warehouses. They shows up as available but you don't know until they try to get them. Datsun 240Z/260Z/280Z Front Suspension (Strut & Shock Absorber) SPRING FRO :: Nissan Parts, NISMO and Nissan Accessories - Courtesyparts.com There is a new option, using Vogtland springs and Stagg shocks, but it's a lowered setup. Your geometry will only change if you lower it a bunch. It's common to lower these cars about 1 - 1.5" with no problems. This shop might be your best bet, considering everything. He really knows the cars and has used parts that don't show on his web page. He restores cars. Worth a phone call. 240Z, 260Z, & 280Z #'s 1,2,&3 - 70-73 240 Z=1 - Steering and Suspension 1 - Suspension 1 - Z Specialties Online Store - If we don't have it in stock, we can get it! And, although you feel like you've been burned by KYB, they do make a good product for stock height applications. You're just hurting your own cause by avoiding them.

-

260z u-joint question/ bad tranny noise.

Never said which oil you chose. As far as synchro help goes I would grade them Valvoline 75-90 plain old gear oil < Redline MT90 < blend of Swepco 201 with ATF. I run Swepco and ATF now and it's great stuff. I'll never use plain old gear oil again. Credit JMortensen for the Swepco advice.

-

76 Z starts but will not idle.

Carb cleaner does work if there's a leak. Idle speed will change when you spray it on the leak.

-

New to this forum! Does anybody have any Bilstein inserts for 240z?

No offense, but you might have some misconceptions about the shocks and other parts. The gas in the shocks is there to keep a dry, inert head over the fluid to help keep the oil from foaming. They're called gas "charged". Any lifting the pressurized gas does is secondary to its main purpose. All of the shocks are hydraulic. Not sure what you're saying about the KYB's. Brand new KYB's can be compressed by hand. There's not much pressure in them. And who wants to take back three year old inventory? erectorset's point about the urethane bushings is probably true, but for a reason a performance oriented person might not appreciate. The rubber bushings will let the body sway out away from the tire more in a turn. Urethane might hold it where it should be and that could allow a rub during compression. I think that the only decent bolt-in shock available these days is the KYB. You might be able to get Tokico's but you'll need to buy extra parts or fabricate spacers and/or gland nuts. The others all seem to require some fabrication.

-

New to this forum! Does anybody have any Bilstein inserts for 240z?

Changing shocks and/or springs to avoid tire rubbing seems off. You're giving away suspension quality to avoid a noise. Do they rub on the outside or the inside? New control arm bushings might do the trick if they rub on the inside. Or you might roll the fender lips a little, if they rub on the outside.

-

Need help with a bolt...

That actually sounds more reasonable. It has a 14mm head if I remember. Not sure why the partsmanual says 10. Pretty sure it's a shoulder bolt though. The shoulder locates the T/C rod. I would just go to the dealer and ask. They have better parts files. Surprising how many of these old parts are still available.

-

Need help with a bolt...

10 x 1.25 maybe. Not sure about the special washer. I don't think that I have those on my 280Z. Datsun 240Z/260Z/280Z Front Suspension (Strut & Shock Absorber) Dealer - BOLT :: Nissan Parts, NISMO and Nissan Accessories - Courtesyparts.com

-

Pumpkin Update: SHE'S HOME!

That's a good point on the voltage regulator. The old external ones are mechanical with several moving parts inside. Your ammeter and a multimeter should tell you if the regulator and alternator are working correctly. It will be interesting to see how often your boyfriend borrows your car. Why would you drive a 510 when there's a Z in the driveway...

-

Gas Cap Question

The fuel pump recirculates the fuel and the engine does not use enough fuel at start to create a significant vacuum in the tank. Could just be coincidence. Have you tried removing the cap before you do the first start attempt? The symptoms point more toward a fuel system (rail and injectors) losing pressure, from a bad/dirty check valve in the pump, or bad/dirty FPR or leaky injectors. The first attempt starts the engine from old fuel or the extra from the cold start valve but there's not enough pressure to supply enough fuel to keep it going. By the second attempt pressure is high enough to keep the engine running.

- CBS show Scorpion's main character drives 240Z

-

RPM is dropping from 1,100 to 600-500

Doesn't this seem more like the classic vapor lock from the fuel supply lines? Hot weather, original carbs, probably mechanical fuel pump.

-

71 Garage Find

Now my right-click copy-paste function doesn't work in classiczcars. Works on other sites though. And the link still goes to generic eBay instead of the car again. Very weird. Maybe it's a virus. Sorry for the clutter, the car is still there at $5200 though. Started a thread about the redirecting and find that the link works in that thread. http://www.classiczcars.com/forums/website-development-bugs/53178-redirectingat-when-certain-links-clicked.html#post464777

-

71 Garage Find

Now it works. Most of them do.

-

71 Garage Find

Doesn't work. You can see the address bar go to "redirecting" when it opens the new window or tab. Mine worked for me once, until the grabber got it.

-

71 Garage Find

It might be out there but all of those links just lead to a list of eBay Datsun parts. I searched eBay though and I think I found it - Datsun Z Series Coupe | eBay Edit - NOT. eBay or classiczcars keeps breaking the link. It worked once then no more. Try putting these words in the eBay search bar - 1971 Datsun 240z Barn Find Edit 2 - I think it's the "key word" grabber and redirecter that's doing it.Can't remember if that's a GoogleAdsense thing, a site thing, or a virus. Pain in the butt, whatever it is. Turned off "Automatically retrieve titles..." in Advanced. Datsun Z Series Coupe | eBay Edit 3 - didn't work. Still redirectingat.

-

Fuel Injection/Fuel pump combination relay options

I'm pretty sure that you could put your injectors on a separate power circuit just like the fuel pump. But there's really no reason not to have enough power to them. The current is dropped through the dropping resistors anyway, they only need enough to open consistently. Gauge power could be put on a separate circuit also.

-

71 Garage Find

Did you leave out a link? Your original link ended, sold, at $10,200.