Everything posted by Zed Head

-

High RPM problems.

Isn't one advantage of the Pertronix, over other electronic ignitions, that you can pop the points back in easily? Might be a quick way to test the Ignitor.

-

Georgia on my mind

Don't you want to know about moving to Georgia? It's not Arizona. They got skeeters and snakes and tings that make weird noise in the night.

- Help with Throttle Position Sensor 78 280 Z

-

Help with Throttle Position Sensor 78 280 Z

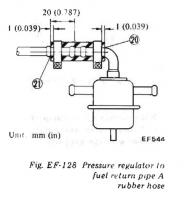

Pictures look great. Well-sized. Looks like someone installed a 75-77 FPR on your 78 fuel rail. It should work fine, but that's why it's not attached properly and has the blocked off port. Not the safest set-up either since the only thing holding the FPR on is the hose clamps on the inlet and outlet ports (unless there's a bolt that I can't see in the picture). If the clamps loosen it could pop right off and the engine would get dowsed with gasoline. Check those clamps and see if you can get a bolt in to the bracket. The part of your situation that seems most important is that the engine died and you had to have the car towed. If it was a simple tuning problem, you should be able to drive around with low power all day. Does the engine start now? If so, it could be a heat-related problem, if not, maybe something broke unrelated to the low power problem.

-

Checking Timing Chain Stretch

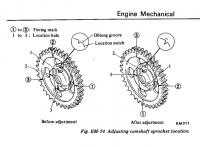

You should be able to just put the new sprocket back on using the same dowel hole - 1, 2 or 3. Assuming that the flaw with the old sprocket is just the fact that they didn't cut the notch in it. Once it's on, you can determine if cam timing is retarded or not. And, if the old sprocket isn't worn out, the only reason to install the new sprocket is to check cam timing. So, you could also get a used one and stick it up next the old one, aligning teeth and 1-2-3 holes, and check notch alignment. Or, if you're good with measuring tools you could even transfer the notch location to the old sprocket and just leave it on. Just offering a new view. Nissan stopped referring to chain stretch in the later ZX FSM's. I wonder if it really has that much effect, considering all of the other things that wear. The funny thing about it is that it moves the power peak to higher RPM (as I understand things). Which is what people who modify usually want to do. My thought has been that one cheap way to make a higher revving engine is to put a used chain on.

-

Turn signal flashing time

How fast are yours now? Maybe they're abnormally slow and a stock replacement would do the job. Need numbers.

- just bought my self a 73 Z having a few issues

-

just bought my self a 73 Z having a few issues

I've found that a hook-shaped pick does the job for the door handle retainer. It's on the splined shaft, you can see it if you try. You can get something like these almost anywhere. The screws for the door handle are deep in the holes on the bottom of the arm rest, plus one under the chrome piece at the top front, which pops off. Big head, about a #3 screwdriver.

-

This guy asks 14.5 k for 24 Valve Goerz Paeco DOHC Head

He'd have to throw in the other head (looks like an N42 with a later cam, internally oiled) to to make it worth considering. And the little stand.

-

Checking Timing Chain Stretch

Found a link on ratsun that suggests some sprockets don't have the mark. Still wouldn't makes sense to have the 1, 2 and 3 numbers, but no mark. Post #12 - does this cam timing look correct? - Engine - Ratsun Forums

-

Checking Timing Chain Stretch

Something seems weird then. One of those three holes should be up near the top so that you can look through it. I think that each one has a notch. And one of those three holes that was under the bolt washer should have the can shaft dowel in it, you can check that. Maybe someone in the past broke the dowel and eyeballed the camshaft sprocket in to place, locking it down with clamping pressure. One of the guys on here who's done more engine work should have an idea. Doesn't look right (to me) for the settings you described.

-

Checking Timing Chain Stretch

Is that picture from when you had everything set to zero? No sprocket bolt, and the holes in the sprocket aren't at the top where the groove is. You might be on the exhaust stroke for piston position. The timing mark actually passes zero twice for each chain sprocket revolution. Check that the cam lobes are both up, not contacting the rocker arms. The sprocket has the 1, 2 and 3 adjustment holes so it should have the notch also, to show the need for adjustment. The first is not much good without the second.

-

Help with Throttle Position Sensor 78 280 Z

What does it do when it lacks power? Does it cough and buck and backfire, or just "bog" when you give it gas, or blubber and choke like it's flooding? With 45 psi you might have been running rich with fouled plugs, and finally fouled too many on the way for the engine to run. Coughing and back-firing is typical of lean, fouling plugs can happen if it's rich. "Bogging" could be timing. I would pull the plugs to see what the few miles of driving did to them (keep them in order 1 - 6 in case you have cylinder-specific problems), test all of the EFI components from the ECU connector that you can figure out from the FSM so you'll know from the start what the ECU sees, and check the timing (pretty common to have someone turn the distributor to see what happens and get the timing either way retarded or way advanced). Didn't realize it was that bad. Good luck.

-

SS Voltage Regulator

I think that the fact that you knocked the cap off with your hand shows that it wasn't properly locked down anyway. So, probably lucky in the long run. You could have spent hours trying to find the source of a random miss, caused by the cap moving around. All of the Z's seem to be on the edge for amps at idle. An extra 100 engine RPM can make a big difference. I've also found that the factory made alternators seem to put out more idle current than the typical aftermarket alternator. Personally, I will always run old Nissan alternators until I run out, over "new" refurbished parts store alternators, but I have several wrecking yards in the area to choose from. And there's no guarantee that more peak output will produce more idle output, the output curve slopes seem to change between various alternator brands. It's a dilemma.

-

Do spindle pins need to come out for springs/insulators?

To add a little to what Jon M. said - on the 280Z you'll need to loosen the control arm inner mounts a little bit to get the top of the strut out from under the fenderwell (I think JM has a 240Z). The 280Z strut is taller than the 240Z so it needs to drop down farther to clear (Blue's three 240Z links may not apply directly). But it is doable, I swapped my rear springs a while ago doing it that way. I think that I might have left the brake lines attached too, but it's risky. If things slip you can damage them. If I recall, I also had to disconnect the halfshafts because they wouldn't drop down far enough otherwise. The thing about these time-savers though, is that after your first try you'll probably get done and say "it would have been faster if I had just taken it out completely". You'll forget something or something will slip or you'll get in a bind and spend time thinking instead of doing. After you've done one, the short-cuts make more sense.

-

280Z Full Restore in 5 months, hopefully.

Whose Goat? rcb is right. Topsy-turvy.

-

Starter question

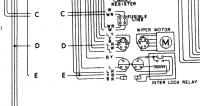

You could reconnect everything to see if the switch is bad. If it still does it, ordering a switch might be a good idea. If not, you've ordered an extra switch. I copied the relay picture. I didn't follow all the traces but yellow/black is power to the starter solenoid (it's where "E" goes). Black/yellow is the other side of the relay, which I think is what needs power. SteveJ probably knows but maybe you went yellow/black, when you should have went black/yellow, and connected switched power to the solenoid.

-

Starter question

I'm going to guess that you jumped the wrong wires. Just because everything worked fine before. On the 76 cars, the power to the starter solenoid and the power to the ignition system are all on completely separate circuits, initiated at the ignition switch. Odds are you've jumped switched power to the starter solenoid wire The wiring diagram for the 260Z is harder to look at but here's a link if you want to dig in - http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/74_260z_manual_wire.gif

-

GM HEI Module Install

Just offering a counterpoint - there are numerous discussions around the internet also about the possibility that the high RPM weakness is either just a myth or is an early problem that was solved quickly. Many, many stories out there about no signs at all of high RPM problems. The cynic in me says that the aftermarket ignition module and coil companies have benefited greatly from this myth, and actually keep it alive with their unsubstantiated advertising claims. If you search, I think that you might find one decent article about the GM HEI system having a high RPM problem. I looked all over and there's very little real evidence of a problem, just repetition of something heard (no offense). I also found a reference somewhere quoting the guy who inadvertently started the initial rumor (might have been David Vizard) saying that his initial comments had been blown out of proportion and the GM HEI system was a good one. It was in a newer fuel injection tuning book in a book store so I may never see it again though. Edit - here's a link to a comment about Vizard and what might have been the book I was browsing. Not FI, but small-block chevys - http://cyberdave.org/HEICoilInfo.html If you read the whole link though, you end up with someone postulating again, with no evidence. It's like the perfect endless discussion topic. Lots of evidence for and lots against, and infinite combinations in between. On the coil - GM actually made an external coil for the early Novas and trucks (late 60's). You can buy it from Rock Auto or a parts store. This gives you the actual GM system, except for the triggering system in the distributor, which is based on the same principle. I have the standard (BWD, not high performance) HEI module and the GM coil on my engine and it works fine with no issues. Not even a sign. But my stock L28 is done pulling by about 5,500 RPM so I never go higher.

- Help with Throttle Position Sensor 78 280 Z

-

Problem removing trans rear extension

Just realized that my comments about the shift rods sliding out of the adapter are for the front cover coming off. Eurodat's comments are more relevant I'm sure, he's spent more time inside these transmissions than I have.

-

Stumped in New Mexico

The procedure is described in the FSM, Engine Mechanical chapter, about pages 18-20. Any 280Z FSM should work. I've found that Nissan changed the shape of the notch to a square groove for the ZX engines so you might look for that also. It's on the back of the timing chain sprocket, right above its hub or center, right in front of the camshaft retaining plate. The oblong groove is stamped or engraved in the plate. I attached a picture of the plate with the notch (it's right below the "4") and the illustration of what to look for. It's something that's easy to do and will confirm proper orientation of many different engine components, all in one shot.

-

vibration

I replaced my chattering Zoom Perfection (from NAPA) clutch with a Rhinopac. I can't say if the chattering of the Zoom clutch came from the clutch or the flywheel (I did not have it refinished before installing) but I can say that the Rhinopac is very smooth and has a lighter pedal (less pressure required). They're both OEM spec. so I think that the Rhinopac might be more precisely made to allow more leverage on the pressure plate. In short, I like Rhinopac over Zoom Perfection.

-

Help with Throttle Position Sensor 78 280 Z

Did he say that you needed a new TPS or are you assuming? You might be misunderstanding what his remarks mean. There are only three positions for the throttle valve (aka position) switch - idle, wide open throttle and in-between. If he ran the check in the FSM and got the right values, then you don't need a TPS. Don't buy a new switch. It's not a variable sensor like on some modern engines. You might need a new mechanic. It sounds like he's guessing and not using the FSM or EFI Handbook, because 45 psi fuel pressure is normal for some modern engines but is way too high for these engines. 36.3 psi is the proper number and he should have known that. High fuel pressure would cause the engine to run rich and the exhaust to smell like gasoline. Old skilled mechanics are sometimes over-confident and will try to figure things out by looking and testing, instead of doing things the right way.

-

Double checking ball joint to control arm torque??

Look at Post #18 here - Suspension Bolts - Inventory - Brakes, Wheels, Suspension and Chassis - HybridZ Looks like there's a mistake in the FSM. You'll need to convert Newton-meters to foot-lbs. Newton Meter Conversion Chart (Torque Units Converter, Metric)