Everything posted by Zed Head

-

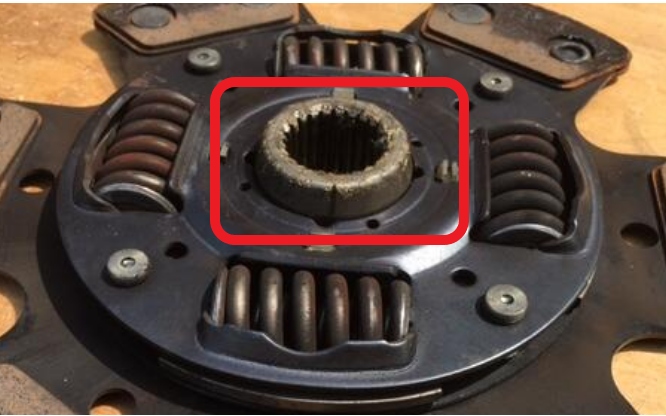

Need clutch disc, not kit

-

Need clutch disc, not kit

A picture would be neat. You're saying that Mcleod's products are of low quality. Which do you have, it looks like there are two types of disc. https://www.mcleodracing.com/sport-compact/c28 Any aftermarket disc should work. Pick your favorite brand. https://www.rockauto.com/en/catalog/nissan,1976,280z,2.8l+l6,1209226,transmission-manual,clutch+friction+disc,10605

-

Clutch Won't Disengage

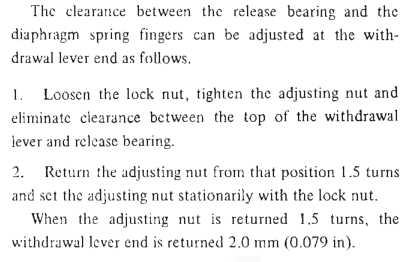

The play looks okay, but does it work? Don't forget to put the return spring back on. Also, with the rubber boot off it's more apparent that you probably have a short throwout sleeve/collar. The fork should start a little ahead of the middle of the hole. Yours is pretty far back. Probably close to hitting the back of the hole at full stroke. It will probably work. Earlier I think I said that problems might happen as the disc wears. But actually things should get better since the fingers get closer to the TOB as the disc wears.

-

Clutch Won't Disengage

The leak in the MC would be internal. Unable to build pressure at a certain point in its travel, then lets the fluid back in to the chamber as the piston retracts. The slave cylinder can contain a lot of fluid inside the dust boot without leaking. You need to get proper travel from the hydraulics. It's critical.

-

Clutch Won't Disengage

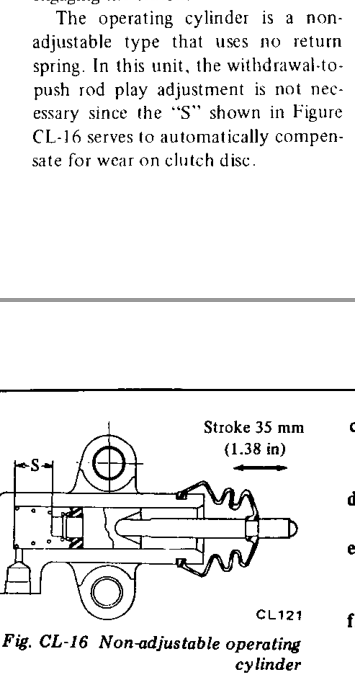

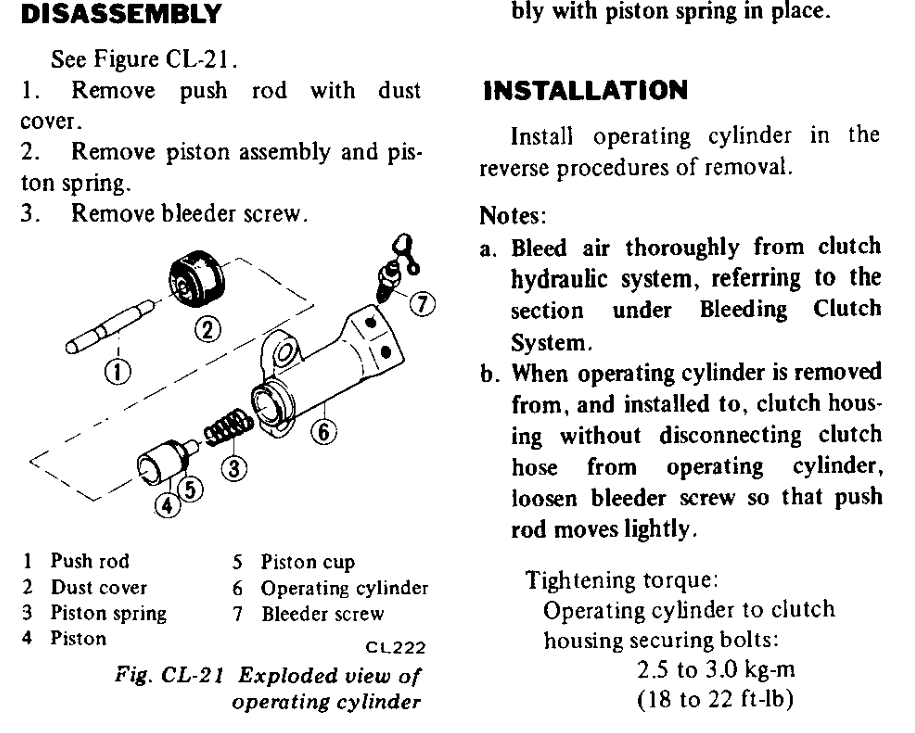

I had a weird situation where the slave cylinder was leaking and I only got 1/2 of the expected travel from the cylinder. It moved when I watched it but it wasn't moving far enough. Could also be a leaky spot in your MC. I would measure the travel distance to be sure that you don't have a hydraulic problem. I think that EuroDat has published the distance that the slave piston should travel. I haven't figured out if Nissan meant that available/possible travel was 1.38" or if the piston was supposed to travel 1.38" when the pedal was pushed. Not clear.. I think that they must mean that it should be 1.38" when you press the pedal, since the end of the bore is open, and full stroke would be essentially unmeasurable. Either way, it would be good for you to know the number. And, if you do take it apart consider getting a later clutch fork and use a self-adjusting slave cylinder. It's an improvement.

-

Clutch Won't Disengage

Never mind. That wouldn't work.

-

Clutch Won't Disengage

-

Clutch Won't Disengage

-

Clutch Won't Disengage

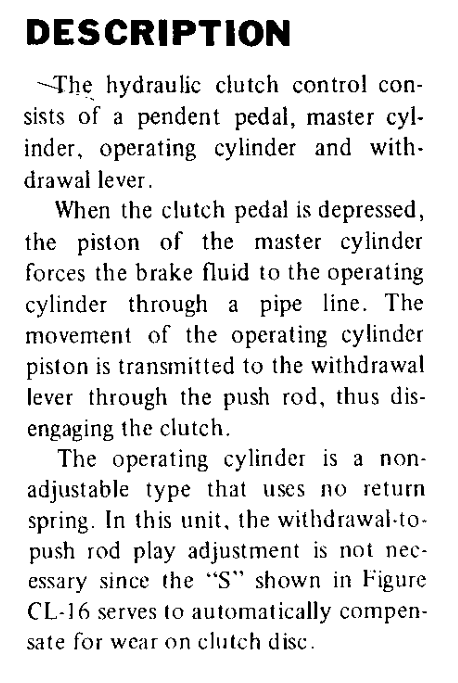

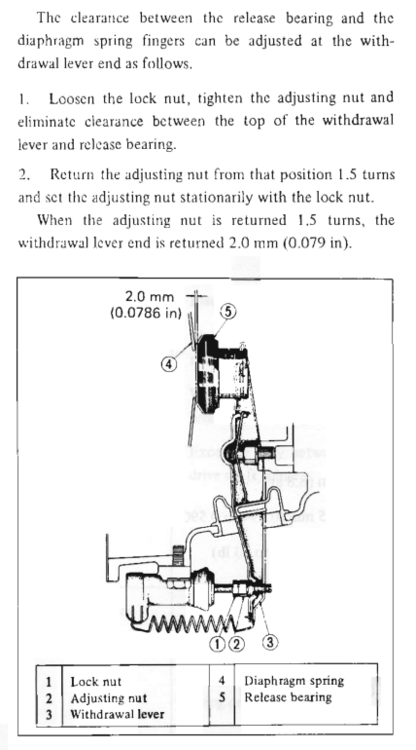

It's interesting that when Nissan went to the self-adjusting operating (slave) cylinder that they put a very light weight spring in the cylinder to take up the play. Which means that the gap gets reduced to zero, but with no significant force. I wonder if that has something to do with the noise that people often hear, that many have assumed is the countershaft bearing. Maybe it's the clutch fork rubbing on the throwout bearing. A person would have to hear the noise, open the hood and reach down to the cylinder and pull the rod back to be sure, I'd guess. Or get a helper to do it. Just a thought I had when looking at how the self-adjuster works. There is no 2 mm gap.

-

resurrecting a 1977 280Z

There's probably no countersink.

-

Clutch Won't Disengage

There's no real "sweet spot" to find. Pressure cannot be maintained on the clutch fork once the pedal is released because the fluid will return to the reservoir. The beauty of the hydraulic system. In other words when you make the rod longer once it touches the fork, (edit) and the fork is touching the pressure plate fingers, you're just using up potential travel if you extend it further. There's no reason for the clutch to slip. If it is releasing fully you should be fine. Good luck.

-

resurrecting a 1977 280Z

There are several. They call it a "friction kit". Use that term. https://www.fidanza.com/pages/catalog-search-sd

-

resurrecting a 1977 280Z

Fidanza's web site is pretty poor, the search engine doesn't find anything, but Google did. Here's an example of a replacement plate. Not sure if it's right for yours or not. Probably best to call them. https://www.fidanza.com/products/copy-of-flywheel-friction-kit-229501?variant=14995559841835

-

Which GM HEI Module ?

1976 Camaro will work. https://www.rockauto.com/en/catalog/chevrolet,1976,camaro,5.0l+305cid+v8,1035065,ignition,ignition+control+module+(icm),7172

-

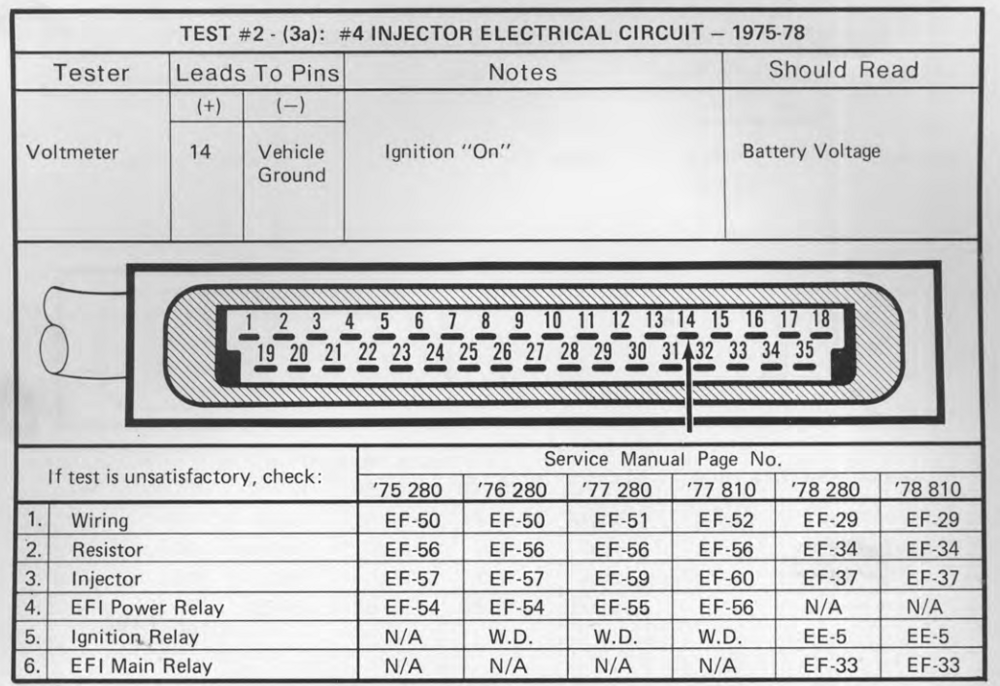

Injector Voltage

Low fuel pressure comes to mind. Clogs, bad pump, bad filter. Easy to check. Very important.

-

Injector Voltage

The gasoline was fine. The injectors just didn't flow evenly. I drove it that way for quite a while. If you told use what "not great" means we could have more fun.

-

Injector Voltage

How long has it been sitting? Here is what my six injectors produced at full flow on my engine after I bought a long-sitting car. That's gasoline.

-

Injector Voltage

Have you calibrated your eyeballs?

-

Injector Voltage

-

Clutch Won't Disengage

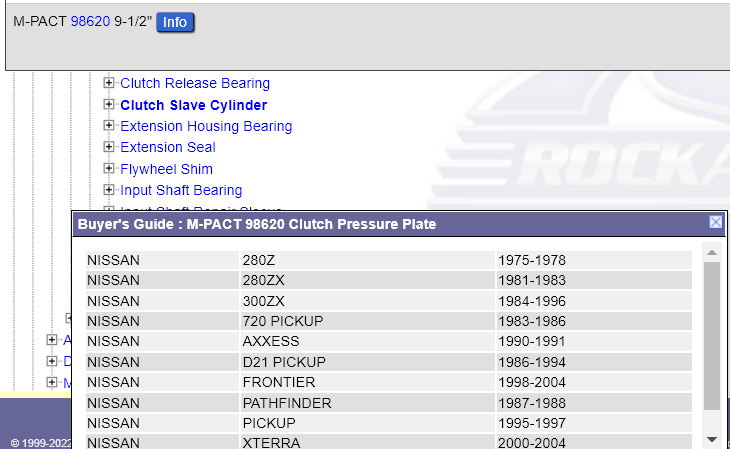

The last 1/2 inch might be the pilot bushing in the crankshaft. You haven't said if the fork is hitting the back of the hole. Looks like the vendor might be right. The 240 mm pressure plate does fit many different applications. I think I might have known that once in the past. https://www.rockauto.com/en/catalog/nissan,1990,300zx,3.0l+v6,1209686,transmission-manual,clutch+pressure+plate,1988

-

Clutch Won't Disengage

Could you post a picture of the receipt? Delete your personal info. Or post the link that you bought it from. Where did you get it? Fidanza drills their flywheels to fit multiple pressure plates. Might be that that kit will work with Fidanza's wheel. But if you were jamming the disc forward while bolting the transmission down it would be held against the flywheel by the shaft. That would be a problem.

-

Clutch Won't Disengage

I found the numbers at the end of that thread. Also added a post. I pulled the numbers from Terrapin Z's measurements, from the ears to the bearing surface. Wonder why there are four. Doesn't really make sense. 32.3 37.3 42.9 46.8

-

Clutch fork throw

I pulled the numbers from Terrapin Z's measurements, from the ears to the bearing surface. Wonder why there are four. Doesn't really make sense. 32.3 37.3 42.9 46.8

-

Clutch Won't Disengage

I'd measure first. The labels in that picture of the four TOB's doesn't actually mean much. It's the pressure plate size that matters, for the Type B transmissions, not the car or transmission. I think that there is a 225 mm version and a 240 mm version for the 280Z's, and probably an early monkey motion 4 speed version for the 240Z's. Basically there's a tall and a short for what you're working with. Anyway, if you take a measurement and know what you need I think that somebody like @Terrapin Z would have one. He actually measured several in the recent past and posted the numbers. I'll see if I can find the thread. It might be at the end of that one I linked, not sure.

-

Clutch Won't Disengage

Just remembered that there is an assumption that the surface of the flywheel is the same distance from the back of the block across all engines and flywheels. It seems reasonable but maybe Fidanza's is not. I doubt that Fidanza would change that critical distance but you never know. Regardless, if the fork is hitting the back of the hole and the clutch fork is solid you need a taller sleeve.