Everything posted by steve91tt

-

240Z good for tall people?

I know the cat bump in the later cars was an issue but I thought that the 240Z's didn't have that problem. My track car is a 1971 and I didn't do anything to the tunnel. Just cut the mounts out.

-

240Z good for tall people?

I cut the seat mounts out of my track car and mounted my racing seats directly to a reinforced plate on the floor. The driver's seat is a side mounted Cobra Monaco Pro and the passenger seat is bottom mounted Prosport from Jegs. I'm 6'3" and the driver's seat is perfect with a full cage and helmet. There is no way my head can get anywhere near the cage when belted in. The passenger seat is too low for me to comfortably see out. If I'd mounted that one on the drivers side I'd have to shim it up an inch or so to see well enough to drive.

-

Best Camera Setup for Z Cars

I've shot professionally for the past few years and I agree with the comments above. You aren't likely to push the abilities of a modern camera at a car show so any modern SLR body will do just fine. Lens choice is a personal taste. I like narrow depth of field shots to isolate the subject from the background. The faster the lens (F/2.8 better than F/4) and the longer the lens (200mm better than 18mm) the narrower the DOF. I also like the perspective you can get with a very wide lens like a 18mm on a full frame 5D, 7D, D700, etc. If you go with a crop sensor like on a D60 or D90 then you will need a wider lens to get the same effect. Camera shopping is fun! Good luck.

-

Your kids' favorite thing about your Z?

-

Your kids' favorite thing about your Z?

My kids (10,10 and 12) love being my pit crew at the race track. They torque lug nuts, help me get belted in, record every lap with a stop watch and they cheer as I work my way by the Porches and BMW's. When the twins were younger I used rides in my 91 twin turbo 300ZX as a potty training reward. Worked like a charm!

-

Triple Mikuni thread

Good news, easy fix! I like your heat barrier idea. Let us know how it works out. I'm always looking for anything that will keep the carbs cooler here in Texas.

-

Mallory Unilite Distributor Wiring

Sorry, you are right. The tach adaptor was needed for my MSD box...not my distributor.

-

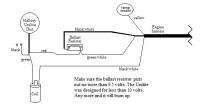

Mallory Unilite Distributor Wiring

This is the wiring configuration that I am using with my Unilite. You are correct, you don't need the OEM ignition module. I also had to purchase a Mallory adaptor to get my tach to work but that's on a 240Z. I can't speak for the later Z's.

-

Looking to do a major engine/transmission switch. Need help and expertise!

V8 swaps are very popular for these cars. However, the information on this site is mostly geared towards cars with original-ish drive trains. Hybrid Z is the place to look. They have compiled a wealth of information on how to stuff almost any powerplant you can think of into these cars. It will take you some time to read through it but I think you'll find the information you are looking for at the following link... http://forums.hybridz.org/index.php/forum/38-faqs/

-

[2012] What did you do to/with your S30 today?

Rebuilt the trans on my 1971 240Z race car. New bearings, seals and and syncros. Should shift much better now.

-

Triple Mikuni thread

Sounds like you found your problem. I'm looking forward to hearing what's stopping flow to some of the accelerator circuits. Keep us posted.

-

getting more HP in 78 280z

Will the stock EFI will handle any significant increase in HP? I thought that if you start putting go-fast parts on the early FI cars you had to go with an aftermarket system like Megasquirt.

-

Differential swap

I beleive the 90+ cars have R230's. This will require some work to convert to use in your car. This thread goes into the details of the various rear end choices nicely... Differential / CV / LSD / HP / Torque / R160 / R180 / R200 / R230 / Diff Mount - HybridZ

-

Triple Mikuni thread

I have the following setup on my L30... 44mm carbs 34mm venturis 150 fuel jets 210 air 57.5 pilots (1.5 turns out) 1.8 needle/seat 45 pump jets I ran the same setup on a bone stock L24 with a set of 145 fuel jets. You can work the air out of the accelerator system by opening and closing the throttle while the fuel system is pressurized. You can do this when the engine is on or off. I did it by driving around stabbing the throttle periodically. It's a little tricky to see if the accelerator pumps are working but you might try taking off the air horns and using a mirror to look down the bore. If you are lean at idle at 3 turns out then you might need bigger pilots but Todd is the guy to ask. Does your idle change the same for all 6 cylinders as you close your adjustment screws? On my L24 I found that some cylinders reacted differently than others. Eventually I found that I could get the smoothest running engine by adjusting each cylinder individually so that screwing the pilot adjuster in 1 turn had the same effect on the engine. In other words, I'd turn the adjustment screw in 1 turn and record the idle change for each cylinder one at a time. I would then adjust the individual adjustment screws so that one turn in resulted in the same effect on the engine. This resulted in some cylinders being set at 1.25 turns out while some were set at 1.75 out. I don't think this is your issue but you can use this technique to determine if all of the idle circuits are working the same. If you have a vacuum leak or some other sort of issue with one carb you may be able to spot the problem child this way. Just my $0.02.

-

Triple Mikuni thread

What is your wideband telling you? I had a fairly bad transition stumble when I first installed my Mikuni's. I solved my issue by adding more fuel to both the idle and main circuit. I also had to purge the air out of the accelerator pump system as Todd mentioned. With a few minor jet tweaks I now have zero hesitation at any RPM or throttle position. It's been my experience that these cars tend to idle and accelerate/transition best at 11-12ish AFR with Mikuni's. Keep at it, once you get them tuned you will love them.

-

Can't get transmission apart

The bolt through the pivot ball trick worked like a charm on the front cover. I then threaded an extra long bolt into the center section and beat on it with a dead blow hammer and a block of wood. It finally came apart. There was no gasket material between the sections. Just some sort of glue. Everything looks new inside. I may not replace the syncros but I will do the bearings while I have it apart.

-

Can't get transmission apart

Thanks Zed Head. I think that this trans has been rebuilt before and assembled with some sort of glue on the gasket material. I've never taken one entirely apart but I've taken the front cover off of my other transmission with no issue at all. This one is very different.

-

Can't get transmission apart

I have been following the FSM and all of the external hardward that you describe is off. I haven't been able to get to the bearing snap ring because I can't get the bearing cover to budge. I've been hitting it through the clutch shift fork hole in the bell housing but I've only managed to ding up the side of the plate. I'll try the bolt in the pivot ball location trick to see if I can get it to move. After that I guess I'll start beating on the case with a deadblow and block of wood to get it to let go.

-

Can't get transmission apart

I'm in the process of rebuilding a 2nd generation 4-speed transmission and I can't seem to get the case apart. All the bolts inside the bell housing and from the center section came off easily as did the pin in the rear section, the speedometer tap and the various plugs. I can't seem to get either the plate inside the bell housing or the case to separate. Am I missing something? Has anyone else had this issue?

-

Initial review of MSA weber 40 DCOE carb kit

Sounds great. I'm going to give it a try on my track car. Thanks for the tip.

-

Initial review of MSA weber 40 DCOE carb kit

Michell, do you have any photos of the Thermo Tec-13575 installed? I'm thinking of doing similar myself.

-

Initial review of MSA weber 40 DCOE carb kit

The "extra wires" near the fuel sending unit need to be energized to support a fuel pump on a 1971. You will find an empty plug near the fuse box that needs to have a hot wire and fuse added to it. Once that is done you should be good to go. I don't remember the color of the wire leading to the empty plug and I don't have access to my car today so maybe someone else can help with the details.

-

Triple Mikuni plumbing questions

I get fuel boiling if I don't open my hood to let the motor cool down after a hard run in the Texas summer. I also get a stumble if I sit in traffic for extended periods of time. Is this because I don't run a return line?

-

Triple Mikuni plumbing questions

This is the one that I use with my Mikuni's... http://www.amazon.com/gp/product/B00029JC6M/ref=wms_ohs_product However, I don't run a return line so I'm not sure it's much help. I used to run an in-line pressure gauge but I removed it after I found it to be very inacurate. I may have just got a bad gauge. I mounted it on a t-fitting with two barb conectors for the fuel line and a female NPT connection for the guage.

-

Clutch recommendations

FYI...If you go with an aluminium flywheel, take care when using the stock clutch bolts. On some flywheels the stock bolts will bottom out in the hole therefore not allowing the pressure plate to suck up tight to the flywheel. I ran into this problem myself and solved it by installing slightly shorter bolts. I didn't notice anything unusual when I first installed the clutch as the bolts torqued normally but when I put the car back together the engage point for the clutch pedal was very low. The clutch worked normally but I could never get the engage point adjusted to where I wanted it until I figured out the bolt issue.