Everything posted by S30Driver

-

Putting in a replacement L-28

The cat is worth $50 to any scrap dealer and they will pick up. Put it toward your motor swap to defer cost.... Might make the wife happy

-

Waterless Engine Coolant?

I think you are being a little hard on Mr. Leno. He is a true enthusiast. His only interest in putting up a video on the Evans product is because he looks for interesting products that can be of benefit the classic car world. I would imagine he received no compensation from Evans other than probably some product to test and possibly endorse it. As far as being a "car expert", his record on marques he cares about speaks for itself. My 2 cents ....

-

Putting in a replacement L-28

If you have the correct tap, maybe its worth chasing and cleaning up the threads on that intake bolt hole and see if that improves the bolt threading in. The torque for the big intake bolts is about 25 ft lbs.

-

Putting in a replacement L-28

#2 Only if the trans mount rubber is split, torn, or perished would I replace it. If it looks ok, just re-use it.

-

ZCON 2021 Roll Call

Sorry to hear you're hurt Charles. Looking forward to seeing you next year.

-

Filter Bypass Valve

-

Filter Bypass Valve

Alright, two concurring votes of confidence is good enough for me!! I'll leave it alone and go with it. Thanks guys!

-

Filter Bypass Valve

That is reassuring.... I have the Zcon drive of about 1600 miles roundtrip coming up. Are you saying not to worry about it and leave it alone for now? Thanks for your input Bruce.

-

Filter Bypass Valve

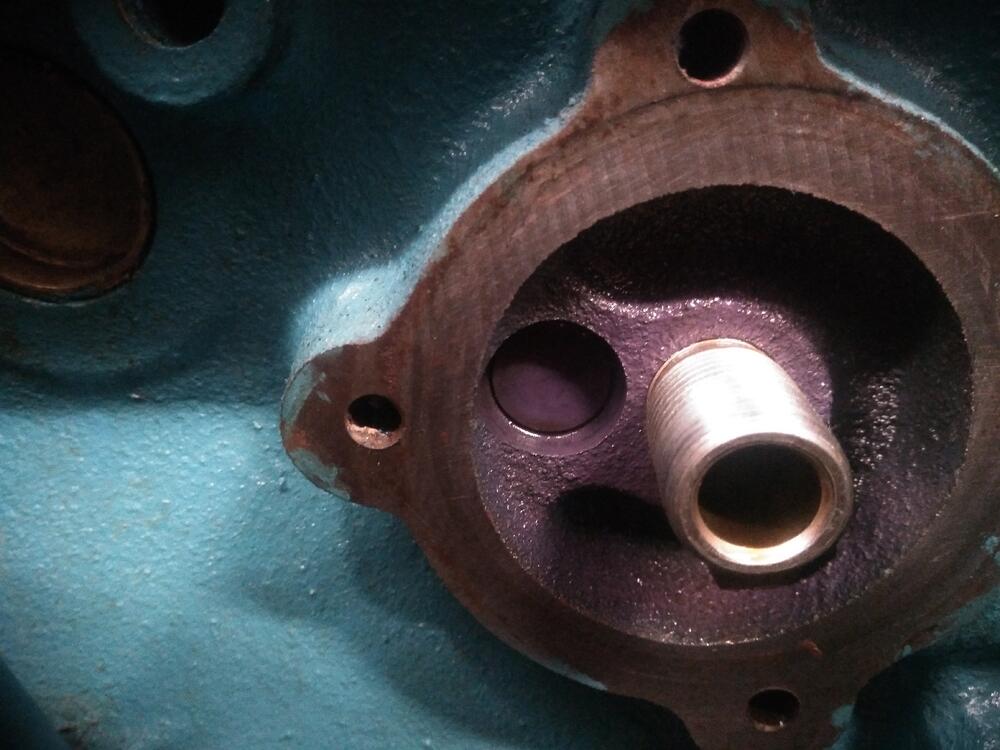

When I recently built up the new motor which now has 300 miles and running well. I somehow missed the plug in the oil filter boss which normally has the spring loaded bypass valve. I changed the breakin oil / filter the other day and noticed it. I must be getting older.... I know it is important should the flow become blocked thru the filter to not let the motor starve for oil. My question is, can I safely drill out what appears to be a plug,then pull it out with something, mabe use a magnet and vacuum to not let any metal chips get ingested and replace it with a new bypass valve? Its a F54 block that was originally set up for a turbo if that makes any difference. Also, my oil pressure seems high compared to my original motor. 40 psi at idle and goes up to 85 psi while driving, varies with engine rpm of course. I think this is normal for a new motor and the bypass valve missing should have nothing to do with it. Turbo oil pump is installed as well. Please ignore the purple paint.... lol

-

Z's on BAT and other places collection

I have seen the pass side drain plug on 70 71 240z's. Not sure when the change to rear sump drain was made. Must have been tough to get those 17mm TC rod nuts started....

-

We're bringin' back the Flat Tops!

Very Nice! My kind of tire shop... Car looks great, looking forward to seeing it again next month.

-

ZCON Colorado

Will you be there this year Bryan? it's only a easy 1700 mile drive. If so, I'll watch for you...

-

Sanden Compressor Upgrade Completion

You're most welcome Greg. In the meantime, keep your eye out for a zx alloy compressor bracket. Easier to modify and far lighter that the cast iron version.

-

Flushing the evaporator

Out of interest ... why do you feel the need to flush the evaporator? You have a new compressor, condenser, & drier, if you kept the system sealed up and not exposed to the atmosphere and the old compressor was not sending chunks of debris thru the system, if it were me, I would leave it alone. Just draw a vacuum down for a few hours to remove any moisture. Just my non ac expert opinion....

-

ZCON 2021 Roll Call

Darn It! Maybe next year ....

-

Sanden Compressor Upgrade Completion

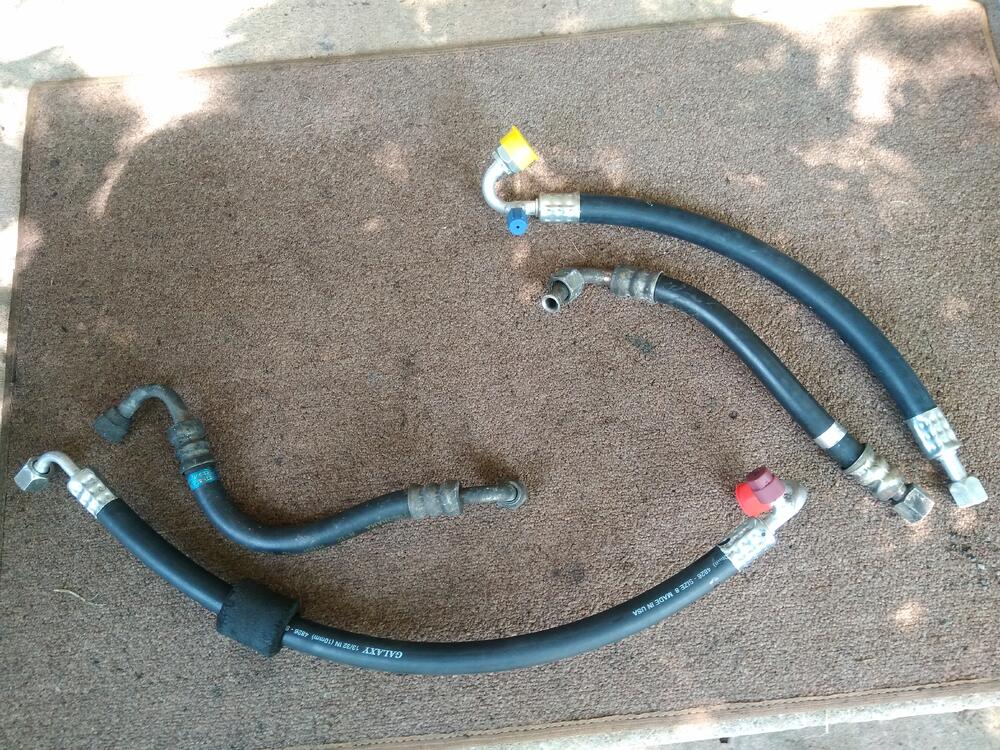

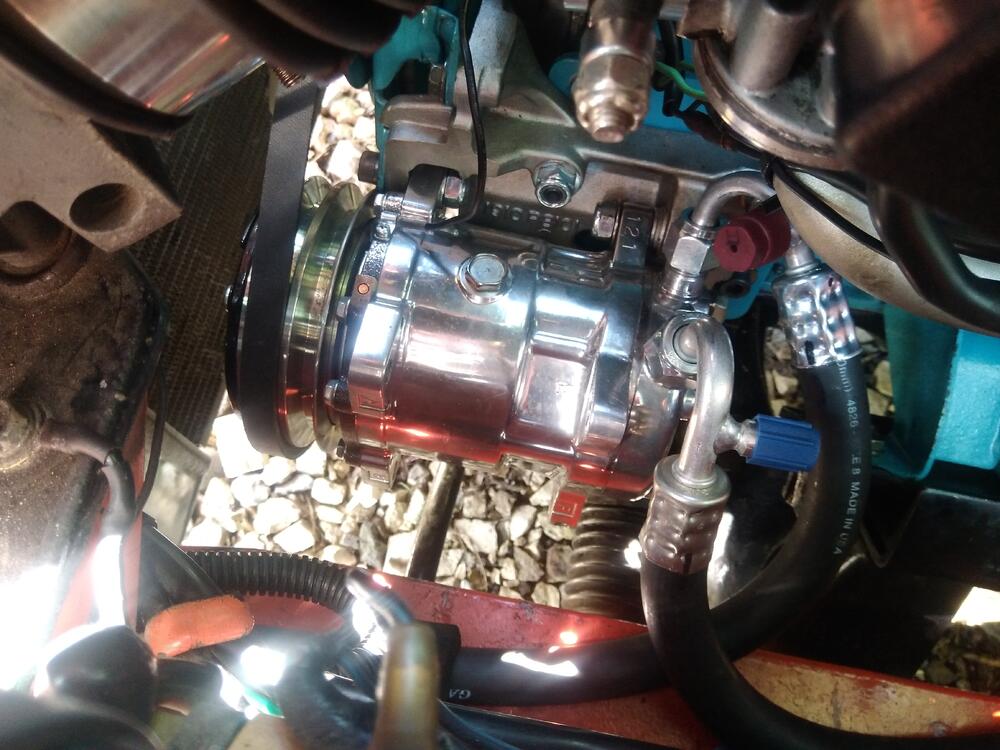

Last Wednesday, I completed the final phase of my fresh motor rebuild with the AC system upgrade to a new Vintage Air Sanden 508 compressor and replacement of the air drier. (my system was already converted to r134a by Nissan years ago) All went well, drew down a vacuum and let it sit overnight - no leaks, charged the system with 27oz of r134a, and now have 42 F air out the vents. Below are the original and new flex line hoses I needed to complete the hookup to the new compressor. Parts needed are 2' of number 8 and number 10 ac hose, a #8 135 degree o-ring fitting with service port on left, #10 135 degree o-ring fitting with port on right, 90 degree #8 flare fitting, and a straight #8 step up to #10 fitting. I was able to use the hydraulic crimper at the local Prairie Grove auto parts store. After cutting the hoses to size and test fitting, be sure to mark the clocking on the 90 degree line at both ends before crimping. The AC lines are not very twistable. Only other issue is I extended the compressor clutch wire about a foot in length as it was just long enough to reach the stock wiring connection and wanted a cleaner look to the wiring. Below is the air drier mounted in the stock bracket with new switch. Compressor mounted and running with stock belt and tension provided by stock idler adjuster. Note the reason for the left / right 135 degree compressor fittings. Could not clock the compressor 90 degrees for better access as the low side fitting comes too close to the frame rail in that position.

-

Wiper Mechanical Failure

Recently, I have noticed a decline in the movement of my passenger side windshield wiper. I had time to investigate it today, and found the source of the problem. The passenger pivot arm that connects to the linkage was slipping and not allowing the wiper to sweep more than a few degrees. After getting access and removing the pivot assembly, I discovered the two welds that connect the shaft to the pivot arm were broken. There is also a spline on that end of the shaft, but had worn, probably sometime after the welds failed allowing the shaft to slip. Cleaned it all up, welded the shaft / arm, lubed and cleaned up both driver & passenger sides, the entire mechanism, all is well in the wipe world again. 😊 Before repair of the 2 welds seen below

-

Drier recommendations

That all makes good sense. Replacing many of the #8 flares that Nissan used with o-ring fittings should be more resistant to any future leaks in the system, which is a very good thing. (although cgsheen1 likes the flares which makes me happy since the only o-ring fittings in my system are on the new compressor) Should get the last fitting I need to crimp the line to the low suction side of the compressor today. It is a #8 flare to #10 hose straight beadlock fitting. Then I should be able to draw down the system and recharge it. Interestingly, I purchased the o-ring 135 degree compressor fittings with service ports from Cold Hose. Nostalgic Air did not have them with the option of the service port either left or right side, only one side. I wanted ease of access to the service ports with the low side clocked left and the high side right.

-

What is the best carpet kit for my 1976 280z

As Zup has mentioned in the past, check with Jim at Chester & Herod Auto Carpets in El Paso TX. They have supplied his carpet and mine. Been in business a very long time. Have all the patterns for the Z cars. You can even get the carpet in wool. Another of the many helpful Jim's in the world.... For the OP's 280, I believe cut pile is oem, not loop like the 240's had.

-

Drier recommendations

You need to find out the fitting size on your new condenser. #10 or #8. The flare fitting on the drier is #8. I am waiting for the adapter from Nostalgic Air to convert from the evap hard line #8 flare to #10 hose for the compressor suction port. You cannot use hard lines directly to the compressor ports since it is bolted to the motor block and can move. That is why Nissan used 1 foot flex lines which I need to extend 4 or 5 inches with o-ring fittings and service ports due to the new and different compressor.

-

Drier recommendations

To clarify what I have done, I have or had a working converted to R134a system but had a very slow leak requiring me to recharge the system every year or so. I have just rebuilt and installed a fresh motor and as part of that, I purchased a new Sanden 508 compressor to replace the factory unit. (the source of my leak) With the new compressor installed, I have to replace the 2 flex lines that connect to the compressor which has the high / low ports in a different location requiring about 5" longer lines and connections with modern o-ring fittings. Nissan used most all #8 flange fittings in the factory system. Currently waiting on delivery of the parts to build and crimp the new flex hoses, then... I can re-charge the system. If I remember right, I think I used close to 2+ 12oz cans to charge the evacuated system. Looking back, the drier was the easiest part of my upgrade, the copper hardlines connected easily, and fits perfectly in the stock bracket.

-

Drier recommendations

You may be right. The switch is another difficult to source part in a high pressure version. I looked and could not find one. My oem switch had a broken contact tang so I had to replace it. If your original switch is good, maybe you can transfer it to the new drier. Maybe someone with more AC expertise will chime in here. @Captain Obvious what say you ....

-

Drier recommendations

Here is the drier I installed, I used a cut off wheel to remove the bracket, ground the weld down, painted gloss black, fits perfect. https://www.amazon.com/gp/product/B003R3PX0Y/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=UTF8&psc=1 I also put in a new switch and removed the factory paint covering the sight glass ... lol https://www.amazon.com/gp/product/B000C2M9NM/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=UTF8&psc=1 I am just completing the refresh of my ac system with its new Sanden 508 compressor, waiting on parts for the new flex line which need to be slightly longer with o-ring ends for the compressor. Got most of the hose parts from Nostalgic Air.

-

Parts Wanted: Need Series 1 Front Fender Supports

The guards / supports have been sourced, awaiting shipment. Will close advert when they arrive. Thanks to all that responded.

-

Parts Wanted: Need Series 1 Front Fender Supports

Thanks much, I'll let you know ....