-

Posts

1,483 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Namerow

-

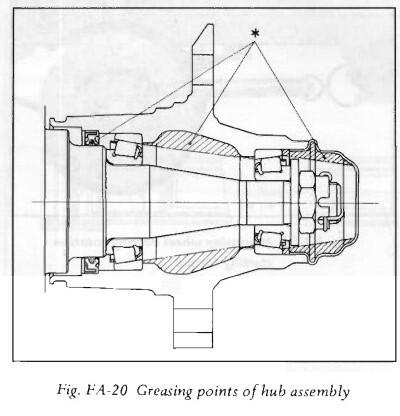

You'll see the same thing in the FSM for the front wheels... I wonder if this has to do with the centrifugal force that acts on the grease when the wheels are turning at speed? There are two grease 'reservoirs' here: one formed by the pocket in the center of the wheel casting, the other along the wall of the dust cap. In each case, the grease will try to flow out to a region with a larger diameter. This would have the pocket inside the wheel casting feeding the inboard bearing and the grease in the dust cap (notice the slightly conical shape?) feeding the outboard bearing. Or... maybe it's not so much a question of having the grease actually flow as it is one of creating some pressure on the grease in the bearing cavities. If it's not one or the other, then the idea of putting grease into these two reservoirs seems kind of mindless. It might also explain why it's not a good idea to over-pack the wheel and the dustcap with grease (the pressure at speed might overwhelm the inboard grease seal). Just my theory. Probably only a chassis or lubrication engineer would know for sure.

-

Interesting. Assuming the same material and coil diameter, the spring constant for a regular coil spring varies as the fourth power of the wire thickness. At 0.116" vs. 0.102", the shorter of your two springs should be 67% stiffer (lb/in). The fully-compressed height of the short spring looks like it would be 3.5 x 0.116" = 0.41". The free height looks to be ~ 75% that of the taller spring, so 0.75 x 1.035" = 0.78". Full compression distance would therefore be 0.78" minus 0.41" = 0.37", so the preload force exerted at full spring compression would be 0.37 x 1.67K = 0.62K, where K is the spring constant of the longer spring. Using the same approach, the longer spring looks like it would have a fully-compressed height of 4.5 x 0.102" = 0.46". Full compression distance would therefore be 1.035" minus 0.46" = 0.58", so the preload force exerted at full spring compression would be 0.58K. So (if I got my math right)... At full compression, the shorter spring will be exerting about 0.62 / 0.58 = 7% more preload force, compared with the longer spring. That's pretty close. In fact, they're probably the same. The shorter spring will be more sensitive to turning the adjustment screw in and out, and it will get from max. preload to zero preload a lot faster... but I can't see that being an advantage. So, why?

-

Hard to see how the Factory counted 5.5 turns for the spring, as it's shown in the FSM diagram. I agree with your count: just under 4 turns (and your long spring matches well with the one on the FSM diagram). Your short spring looks like it's only 3 turns. However, the wire gauge looks like it may be thicker. Did you measure it?

-

IIRC, some Z shift levers use a black rubber/plastic grommet at the top of the shaft. That would serve to fill in the gap that you have with your boot. Not sure where you'd be able to source the grommet. It may take a little patience and/or ingenuity.

-

I fine illustration of a shade tree mechanic at work.

-

My two swiss S30Z Fairlady Restoration build thread

Namerow replied to JDMjunkies.ch's topic in Build Threads

Impressive level of detail. I originally intended to ask whether you have any pictures of what this kit looks like once fully assembled, but then I found this video on Youtube... I'm really impressed. These kits can be disappointing if the proportions are off. This one looks perfect. Except for the wheels... -

My two swiss S30Z Fairlady Restoration build thread

Namerow replied to JDMjunkies.ch's topic in Build Threads

US $899.00 That seems like an attractive price, esp. when compared with the amount of time and labour required for a DIY repair and restoration of a cracked original dash. I wonder what Just Dashes are charging these days to refurb an S30 dash? You'd need to also take into account the fact that their solution requires 2-way shipping, whereas the JDMCP dash cap ships outbound only. -

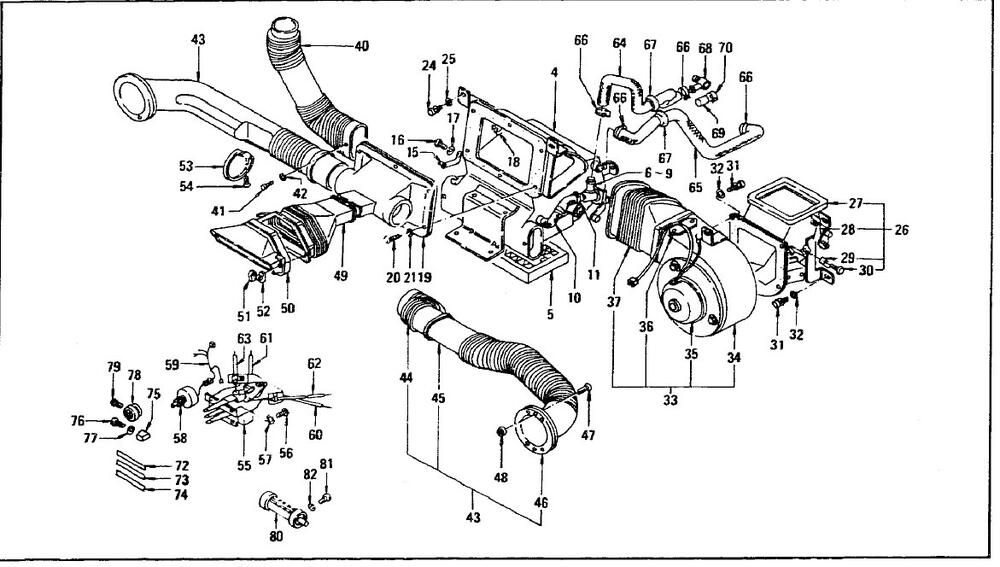

Item 50 in the FSM illustration (exhausts through the rotating chrome grille, Item 80). Cutting and then gluing the foam pieces around the duct's inside surfaces is finicky work. I can only assume that Nissan decided the benefit outweighed the additional manufacturing cost. You need to use open-cell foam for this location.

-

Maybe too late now, but I posted printable templates for all of the heater boxes, flaps and ducts in 'Resources - Knowledge Base'. Might save you some time. Don't overlook the foam liner for the centre air outlet duct. It's there to reduce air rush noise. Also: Be careful with the edges of the vinyl-faced flap coverings. They may need some edge profiling or cutting back to keep them from snagging as the flap moves from 'open' to 'closed' position. You don't want those things coming loose after you've installed everything back under the dash.

-

I don't recall seeing any restoration write-ups that have been specific to the centre console. I think you'll find (limited) discussions on the topic as part of broader write-ups on Interior restoration. If memory serves, the full-restoration thread done by CSCZ member @wheee! was based on a 280Z, so you might find some tips there. Most of the coverage that I remember deals with repairing the consoles for earlier 240Z models, which were prone to cracking where the choke lever assembly attaches. Perhaps it would help if you provide some details about the condition of your console, which will help us to understand why you think you need to replace some of the hardware. As for the removal/reinstallation process, the Factory Service Manual (downloadable for free from the 'Resources' section) should be your first pint of reference. SEM 'Landau Black' paint is generally considered the go-to paint for reconditioning the Z console. Most members use a 'chrome' pencil to restore the trim highlighting. Cracks can be repaired with cautious use of the ABS plastic cement used for plumbing. If its a long crack, you should probably reinforce the back side with a secondary layer (an old credit card or hotel key card works well for this purpose).

-

Agreed. @cgsheen1 Would you mind spending a couple of extra minutes to post your write-up in the CZCC 'Knowledge Base'?

-

Well, the good news -- maybe -- is that Pilkington (Britain-based, with manufacturing operations in several countries worldwide) has been owned by Nippon Sheet Glass in 2006 and now operates as a NSG subsidiary. Pilkington's website describes their automotive business as follows: " Operating as a single global organization serving the Original Equipment (OE) and Local Automotive Glass Replacement (AGR) Aftermarket sectors... The North American aftermarket operations supply laminated and tempered glass for the automotive glass replacement market. All products meet or exceed Federal Motor Vehicle Safety Standards. Products are shipped from its distribution centers in Columbus, Ohio and Phoenix, Arizona to external retailers and wholesale customers and its network of company-owned wholesale service centers throughout the US... Windshields, sidelites, backlites, accessories and specialty AGR products are included in the customer offering of Pilkington North America AGR". The British Pilkington website includes 'Pilkington Classics' products and lists hundreds of replacement items for older cars. That list includes both a 240Z windshield and backlight. It looks like they operate on a custom-order basis and no prices are shown. I suspect they wouldn't be interested in filling single-unit orders, but would be amenable to an order for 20+ from someone like MSA.

-

I believe that the 'XXX"' moniker is Pilkington's short-form for their 'Triplex' line of laminated automotive safety glass. Pilkington has been manufacturing automotive glass products at a plant in Collingwood, Ontario since 1973. Hard to believe that they'd be engaged in short production runs of replacement glass for vintage cars, but you never know. A brief write-up that I found for Pilkington North America says, "Its sales are made up of 70 percent automotive products (57 percent Original Equipment and 43 percent Automotive Glass Replacement) and 30 percent architectural". It would be interesting to know how long ago your MSA-sourced windshield was actually made.

-

Some suggestions for new gaskets: - thin (1/32") , closed-cell neoprene sheet (Michael's craft store) - the material used in those stretchy exercise bands (Canadian Tire - sporting goods section) - lid from a margarine tub (soft polyethylene) I really don't think there'll be an issue with vibration damping, but at least it'll be easy to go back to paper if there is. If you want to try sealant instead, how about strippable window sealant (DAP product, available at CTC). I just cut new ones from paper gasket sheet 🙂

-

Nice to have you back again! Looking forward to your always-insightful assessments and always-creative solutions.

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

Namerow replied to 240ZBUILTBYME's topic in Build Threads

I may be completely off the mark here, but I wonder what it would cost to ship a rough-but-solid 240Z chassis from the US west coast to your location in Perth. I'm going to guess US$10,000. Add, say, $2,000 to hire someone trustworthy in the US (CZCC member?) to act as your buying/shipping agent. Add $US 10,000 to buy the car. Let's say, US$25,000 when all is said and done. Using this approach, the car might need a bit of metal work but it should be within your means as DIY work. I wonder if this might prove to be a much faster route toward your end goal? Keep in mind that you never know where you'll end up if you hire a local commercial shop to do the metal work on your current Z. Unknowns: 1) total cost; 2) days/months/years to complete; 3) quality of work delivered; % of work actually completed before either the price goes up or you lose patience). As tempting as it might be to turn your Z over to a commercial specialist, it may just open up a completely new can of worms. It can be de-risked by using progress payments based on completion milestones, but I doubt that most shops are going to be willing to sign such a contract.- 344 replies

-

- 1

-

-

1970 240Z Works Rally - the road to restoration

Namerow replied to xs10shl's topic in Open Discussions

Thanks for the explanation and photos. It takes a brave man to drill a 3mm-dia hole down the 6" length of a wheel spindle. -

Re Q1 and Q2, go to 'Resources' - 'Knowledge Base' - 'Wheels, Tires and Brakes'. I just uploaded a summary on the topic. Hopefully, it ill provide you with the guidance you're looking for. Re Q3: In its OE form, this hose (comes in two sections: 1) engine-to-check valve; 2) check valve-to-mastervac) is molded to some very shapes. If you go with aftermarket braided hose, you'll need to figure out how to route it so that it clears all of the surrounding componentry. It will be nearly impossible to achieve the bends that are molded into the OE hoses. Both hose sections have the same ID, OD and wall thickness. By my measurements, these are: 9.5mm, 17mm, and 4mm (the fittings over which the hose ends fit measure 10mm OD). I was not able to find any aftermarket braided hose that exactly match these specs. You can go either slightly under on ID (9mm) or considerably over (12mm). The best choice seems to be 9mm, but you'll probably need to soak the hose ends in boiling water prior to installation to make the rubber pliable enough to stretch over the fittings. One vendor selling high-quality braided ('Continental' brand) aftermarket hose is Bel-metric. If you can find NOS hoses, that would be the best way to go (but expen$ive). Good luck.

-

1970 240Z Works Rally - the road to restoration

Namerow replied to xs10shl's topic in Open Discussions

Please explain how the drive for the Halda unit's is accomplished. -

Reading recommended torques for fasteners always makes me scratch my head. It's my understanding that these values are usually* aimed at achieving sufficient 'thread bind' (my term) to prevent the fastener from loosening in service (* notable exceptions being locations like head gaskets, where the goal is to generate a required clamping force). They'll also keep you under the point of snapping the fastener or stripping the threads. It's also my understanding that these recommended torque values are predicated on clean, dry thread surfaces. That's certainly the case during factory assembly, but rarely so after the vehicle has entered service. For those of us who live and drive in the 'salt belt' areas, oiling the threads or applying Copaslip or some other type of anti-seize lube is normal practice (to ensure that an impact wrench won't be needed to take things apart a couple of years later). I can only assume that 'thread binding' goes out the window because of this, leaving just the lock washer to keep things buttoned up. Except that I think I recall reading an article which said that split-ring lock washers don't really work very well... And you can't use thread-locking compound on threads covered with lubricant. Comments?

-

Truly unfortunate that the suspension aftermarket suppliers are so biased toward 'performance' in their choice of the urethane grade they use for these bushings. I suppose it makes sense for a 3000 lb + American muscle car or for competition use, but it's way too stiff for a small coupe of sportscar being used on the street and highway.

-

We'll know the answer to that question after you've located the NAPA kit.😄 I suspect that the internals didn't change over the design history of that valve. Base plate, levers, mounting holes, yes. But cylinder, cap, plunger, rod and seal --- less likely.

-

Here's an informative, UK-based website that explains the process of rubber hardening and offers some procedures for restoration. https://www.martins-rubber.co.uk/blog/restoring-damaged-or-weathered-rubber-seals-a-guide/ In line with dutchzcarguy's comments, they say: "For smaller, lightly weathered rubber seals, a simpler method is sometimes just as effective; boil some water in the saucepan, add a small amount of soap, and submerge the seal. Every 5 minutes or so, remove the seal using tongs and test its flexibility and condition. The time taken for the rubber to be restored will vary from case to case, but it can be just as effective, and less labour intensive than the previous method! Scrubbing smaller, lightly soiled rubber seals with almond oil is also an effective, simple option, restoring lost flexibility and cleaning away dirt and grime."

-

Here's the article that referenced the NAPA kit. Created by 'Palladin' and uploaded to the Zcar.com website many years ago. 280ZX Heater Cock Rebuild (auto-cock, pull type).pdf