-

Posts

1,483 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Namerow

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

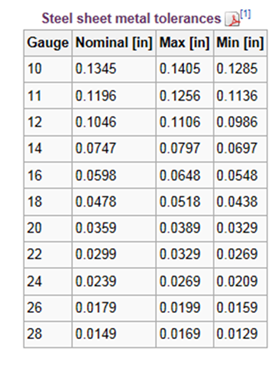

Sorry, I missed this earlier note from @grannyknot. Wish I could remember where I got my gauge chart from (it dates back several years). The discrepancy between GK's values and those from my chart are large, so I just went looking for another source and came up with this one from machinemfg.com (website for a machine manufacturer). I wouldn't call it a definitive source, but the values coincide with the chart that I posted... www.machinemfg.com/sheet-metal-gauge-sizes-chart-inch-mm/#Sheet_metal_GAUGE_thickness_chart So then I searched for a chart for the American Wire Gauge (AWG) and discovered that its values agree with GK's... www.powerstream.com/Wire_Size.htm None of my sources are definitive. If someone wants to post the tables from an accepted engineering reference like Shigley's, that would resolve the issue once and for all (I never could afford that book when I was in school and just used my employer's copy after I got out into the workforce). It appears, though, that we've tripped over yet another facet of wacky world of 'gauge' measurements -- that is, that gauges have different 'thickness' values, depending on whether you're looking a wire diameter vs. sheet thickness. Another vote in favor of metric. -

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

Truly harrowing how such a thick piece of steel can be eaten through by rust. I suppose it has to do with its location (up front and down low) and the moisture-retaining space created in the gap between it and the inner fender apron. Maybe residual warmth from the engine after being parked helped out too. There must have been a lot of salt-belt Z's that were just one pothole-in-the-middle-a-hard-corner away from having the front crossmember part company with the frame rails. On a similar note, I remember back in the day hearing a story about a Z in Montreal that broke in half after a minor fender-bender ? -

I went over to my local small supermarket (would that be a 'mini-market', or just a 'market'?) on Tuesday morning. Arrived at 8:00AM for the seniors' hours (yes, I qualify -- and by a large margin, unfortunately). The store management had decided that they could handle 30 people inside at a time without getting people too close to one another. At 8:00AM (store opening time), the first 30 customers had already been let inside and I ended up at the back of a 15-person queue lined up outside. The speed of the line was painfully slow. Or so it seemed anyway. It took well over 30 minutes before I got into the store, meaning that the line was advancing in increments of about 2 minutes. Next time, I'm going to arrive 15 minutes early so that I can be in the group of 30 who are allowed in en masse when the store opens at 8:00.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

One of the build threads on this site provided a step-by-step fabrication procedure for this exact piece. Unfortunately, I don't remember which thread it was. Maybe someone else will. It basically made up the piece in the form of a set of flat panels. Only straight-line bends and cuts were used. He had to weld in filler pieces to create the floor and the front and rear vertical walls of the pocket. If you think of how you could create the piece using cardboard and tape, you'll get the idea. It's too bad that the answer to this kind of question has to rely on the memory of other readers and contributors. One of the weaknesses of sites like CZCC is that the search tool depends on the words that the tread's author uses to describe their work. For example, what would you call this particular piece? One person might call it a 'doubler'. Another might call it a 'reinforcement' or an 'insert'. There's also the distinct possibility that the author of the build thread that I'm thinking of may have described his procedure without ever giving the piece a name. -

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

I like the second table, esp. the fact that the standard dates back to 1922 and therefore encompasses the period when the S30 was being built. It indicates that the 1.1mm thickness offered by contemporary supplier Parker Steel (see my earlier entry in this thread) is not really relevant to the sheet used for the S30 body panels. It looks, instead, like 1.2mm (0.0472") would be closer to the truth. The JFE brochure provides some interesting insights into the cross-section of sheet steels available to modern-day automotive/manufacturing engineers for body pressings. With techniques like hydroforming and materials like high-strength and ultra-high-strength now available, things are a lot different than they were back in 1969. -

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

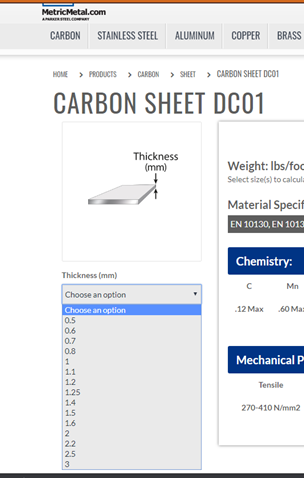

We'll probably never get a better measurement of the factory floor thickness than that. Closer to 1.1mm than to 1.2mm, so let's call it 1.1mm then. BTW, both 1.1mm and 1.2mm are, according to a modern supplier of rolled sheet steel (Parker Steel / MetricMetal.com), legitimate standard sheet thicknesses for bulk metric rolled sheet... Unfortunately, this is one of those cases where the measured thickness doesn't align very well with American gauge standards... 0.044" places the floor panel right at the lower (thinnest) boundary for 18-gauge. Conversely, the upper (thickest) boundary for 20-gauge is just 0.0389". So, we can consider the factory floor panels to be either thin-ish 18-gauge or way-out-of-spec 20-gauge. We can also say that the floor panels are the same thickness/gauge as the main outer body panels (which, interesting to note, are commonly considered to be "20-gauge" but are, per my notes above, closer to 18-gauge than they are to 20). In the end, 1.1mm is probably the correct representation. Comments welcomed. -

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

A key panel not reported on yet is the floor pan. Anyone? Easy to measure by pulling one of the drain plugs, but requires a vernier set up like CanTechZ's in order to measure properly. -

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

Although it's now 30 years old, 'Carroll Smith's Nuts, Bolts, Fasteners and Plumbing Handbook' provides some great insights into fastener technology. Smith was an important part of the Shelby American racing story and a respected member of the American pro racing fabricators' community for many years. He is best known for his 'Prepare to Win' and 'Tune to Win' books, which were racers' bibles in the 1980's. -

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

Updated chart... Panel Location Measured Thickness (t) Source Gauge (derived from ‘t’) Gauge (reported) Source Front Apron (engine compartment) 0.032” Jfa.series1 20 20 Grannyknot Tabco repair panels (all) 20 Manufacturer ConverTT Klokkerholm repair panels (rear quarter) 22 ConverTT Thick-gauge panels & pieces (which ones?) 18 2manyZs kmack Lower Front Frame Rail (OE) 0.050” Carl Beck 18 18 ConverTT Lower Front Frame Rail (ZeddFindings) 0.062” Namerow 16 Upper Front Frame Rail (‘horn’) 0.054” Carl Beck ~ 16 Front Valence Panel 0.032” Namerow ~ 20 Front Crossframe 0.076” Namerow ~ 14 Door – outer skin 20 ConverTT Inner Rocker Panel 18 ConverTT Radiator Support 18 + 20 ConverTT -

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Namerow replied to Namerow's topic in Body & Paint

Well, it could be a lot worse, you know. In England, they came up with something called the 'British Whitworth' system for fastener threads and that is a standard that defies comprehension (I can hear keyboards in Britain warming right now and I expect that we'll shortly be seeing explanations about why BW is actually the best system in the world ?). Here in Canada, our government decided way back in 1967 that metric was the way of the future and decreed that it would be the national standard from that point forward. Unfortunately, our neighbours to the south didn't completely agree (although large parts of the American industrial community did, including the auto manufacturers). Canadians of my generation (boomers) have adapted reasonably well to jumping back and forth between pounds and kilograms, and inches/feet vs. centimeters/meters. Depending on what you're shopping for, the preferred measurement could be metric or it could be fps (sometimes both!). Some of our food containers have truly unfortunate metric sizings (454ml, for example), because the container is actually sized in the old 'quart/ounce' system but labelled to adhere to the legal metric requirement. Speaking of quarts and ounces, did I mention that our 'Imperial' quarts and ounces are not the same as our American neighbours' quarts and ounces? I suspect that younger Canadians can only function in metric. All of these measurement standards have been made to work acceptably* when kept confined to their own geographic sectors. It's only when you start mixing them that things get difficult. (* Well, sort of acceptably. In engineering calculations, the fps system requires an unfortunate concoction called 'slugs' in order to make things work out.) -

I've been reading another thread that focuses on the new floor and frame rail stampings being offered by a shop in Florida (name?). I noted that there seems to be uncertainty over the actual OE panel thicknesses used for the S30's panels and stampings. Given the shear number of experienced S30 restorationists who have been participating in the CZCC website over the years, I'm a little surprised that we don't already have an in-place consensus on the gauges of the factory floor and rail stampings (not to mention all of the rest of the S30 structural and body panels). One would have thought that this would have been discussed and agreed upon long ago? @Patcon @ConVerTT @grannyknot @240260280 And yet... I've never come across a posting that pulls all of this information together in one place. So... here's a table that shows information that I've either collected from others in old posts or measured by myself from pieces from my 1970 and 1972 Z's (and the replacement frame rail that I ordered from ZeddFindings) (worth noting that measured thicknesses don't always line up cleanly against American gauge specs. My guess is that its because the Nissan OE panels were created from metric-spec steel sheet sourced from Japanese steel mills.) If you have a panel thickness measurement that you'd like to offer for any of the S30's panels or major stampings, maybe you'd like to consider posting it here so that we can build up a more complete library. Or, if you already have your own table of panel thicknesses, why not post it here so that everybody else can benefit? Panel Location Measured Thickness Gauge (reported) Gauge (derived by Namerow) Measured (or reported) by Front Apron (under Battery Tray) 20 Grannyknot Tabco replacement panels 20 manufacturer Thicker-gauge panels & pieces (locations?) 18 2manyZs, kmack Lower Front Frame Rail 0.050” 18 Carl Beck Lower Front Frame Rail - Zeddfindings 0.062” 16 Namerow Upper Front Frame Rail (‘Horn’) 0.054” ~ 16 Carl Beck Front Valence Panel 0.032” ~ 20 Namerow Front Crossframe 0.076” ~ 14 Namerow

-

In all my years living in various parts of Canada, I don't think I've ever seen anything like that. Thanks for sharing. BTW, snow-packing in and around air inlets can be one of the most challenging aspects of vehicle design and development. It's really difficult to simulate properly in a test chamber and climatic wind tunnel and field testing can be a hit-and-miss affair.

-

Probably a lot stronger than most Z's are when they first go up on a rotisserie!

- 439 replies

-

- 72 240z

- frame rails

-

(and 1 more)

Tagged with:

-

The numbers are probably accurate but, as CO has pointed out, may be difficult to apply real-world results. Perhaps we should get back to your experiences with your equipment. We can draw conclusions (possibly wrong ) afterwards about how they relate to the specs. The choice between spot-welding vs. MIG stitch-welding seems a really under-discussed part of the hobby-restoration process.

-

I'm inclined to agree. It can be really challenging to translate engineering specs into real-world outcomes. However, some of us like playing with numbers, so... The duty cycle (%) means that the machine can sustain the stated power output for x% of the time. If the machine is rated as 1.6kVA with a 50% duty cycle, it means that it can produce a stated output of 1.6kVA for, say, 2 seconds, provided that it gets a 2-second dwell time before the next actuation. Or at least, that's the way you'd interpret it for a MIG welder, where the operation tends to be somewhat sustained (as in running a 1/2"-long bead). However, for a spot welder it's a little different. Here, the normal electrical operating mode (selected by the operator, but controlled by the machine) is a continuous and rapid on-off cycling (1 time unit 'ON' followed by 1 time unit 'OFF' = 50% duty cycle). For reference, notice the 'square wave' icon next to the green indicator light on the machine shown in the video. So: the 'n' in 'Sn' means 'normale'. This is written as 'conventional power' on British-spec welders. Probably stated as 'regular operating power' or 'regular duty cycle' in North America. I do not know what the 'p' in 'Sp' means for your machine, other than the fact that it's probably tied to the 'I2p' current rating. I do know that 'I2 cc' refers to the machine's closed-circuit (or 'short-circuit') current rating.

-

I lifted the '1.6kVA' rating from your photo, which I took to be the unit your are using. There are two things in play with these welder ratings: When an electrical device relies on power bursts to do its job, the basic electrical power formula of 'P = V x A' is too simplistic and doesn't (directly) apply. That formula is most appropriately used for continuous conditions, such as calculating the power delivered by an electrical transmission line. And even in that case, there are correction factors that need to be used. The power rating for a welder only makes practical sense if it's measured and stated specific to a particular duty cycle (50% in this case). You`ll see a similar approach used for MIG welder ratings. Back in my days as a mechanical engineering undergrad, electrical engineering ratings and calculations always gave me a headache. They still do.

-

Suggest you just go to your local ATV/motorcycle shop and buy a pair of the Kawasaki u-joints. They work fine.

-

SEM 'Landau Black' vinyl paint. You'll need to clean the color area carefully (follow the instructions on the can). SEM products can usually be found at local auto parts suppliers. It might be easier (and even cheaper), though, to just buy a replacement lever -- new or used -- that's in better shape..

-

I decided to create a separate, new Topic to better explain the repairs that I did for my 70 Z's ashtray. It's posted (with a few pictures) in the 'Interior' section. More, and more accurate, details about what I did.

-

Written in January 2020 This little mini-article documents the repairs that I made to my 70 Z's ashtray. Pictures follow at the end. Like many of these ashtrays, the hinge pieces had failed, causing the lid to come adrift. The ashtray isn't much good in that shape. In fact, it doesn't even look good cosmetically. If this is the case for your ashtray, your options are pretty straightforward: Repair or Replace. I think most owners take the 'replace' route, but NOS ashtrays are pretty $pendy (US$1,200 new or $1,000 refurbished from JDM-Car-Parts.com, as of January 2020)). If you don't have the budget, you do what you have to do. No one wants a gaping hole in the console of their otherwise-perfect Series 1 interior. I chose the 'repair' strategy partly because I was trying to keep my project budget under control, but equally because I get a lot of satisfaction out of restoring things. Before I discuss the details of what I did, I think it would be worthwhile to briefly discuss why these ashtrays fail in the first place. There seem to be a few culprits at work: The little helical spring is too strong. This not only overloads the plastic hinge bosses as the lid opens and closes, but also creates an high shock load in those parts when the lid is allowed to snap open (as is usually the case). The type of plastic used to create the main ashtray molding is really brittle (it seems like a 'bakelite'-type material, presumably chosen for its ability to withstand cigarette and cigar burns). That means that it's extra susceptible to stress cracking where high loads exist -- and that seems to describe the situation for the loads that the molded-in bosses take from the tray lid's hinge pins. The tray lid's pivot arms (or 'ears') are molded with sharp interior angles where they meet the underside of the lid. More stress risers. More cracking. In the case of my ashtray, all three problems were on display. 1) The hinge-pin bosses were cracked on one side. On the other side, the top of the boss was missing altogether. As an added nuisance factor, a PO had attempted to repair the one of the bosses using what appeared to be contact cement (now there's an optimist!). 2) The tray lid's RHS pivot arm had snapped off at its root. 3) Both of the threaded hinge pins were missing. These are parts that don't show up on eBay. In fact, I couldn't even find a picture to let me know what they looked like. All I knew was that they threaded into the bosses (presumably to allow the lid to be assembled to the tray). Replacement Spring The little hairpin spring has a required 'relaxed' configuration to make it operate with the right over-centre action when the lid reaches the half-open position in its travel. Too much tension and the lid will slam against its stops (see above). Too little tension and the lid action will feel 'floppy'. Also, there are little 90-degree tangs at the ends of the arms that fit into holes in the tray wall and the lid arm. I didn't expect to find anything suitable in my little box of oddball springs. I also didn't expect to see a replacement OE spring up for sale on eBay. And it isn't exactly an over-the-counter item you can order from a hardware jobber. The only way forward was to make my own. This isn't as hard as it sounds. Regular, untempered steel wire works fine for little springs like this. With limited travel, the spring material never gets taken past its elastic limit, meaning that it never takes a stretched set and always stays 'springy' (note: in cases where the required extent travel is more extreme, it's easy to put a bit of temper into the spring after you've formed it by heating it red-hot with a torch and then quenching it in an oil bath). As mentioned earlier, evidence suggests that the Nissan OE spring is too strong (tempered wire, and also too thick), so there was no point in trying to slavishly copy that part of its design. After some trial and error, I ended up using 0.044" wire (that's a bit under 1/16" and roughly equates to AWG 18 or ~ 1mm). I wanted my new spring to have about the same coil diameter as the OE spring -- that is, an OD of ~ 3/8" or 14mm. As a forming mandrel, a 1/4" drill bit looked about right. I clamped the bit in my bench vise so that the shank (smooth part) projected horizontally out one side of the jaws. Then, holding a 12" length of wire in my hands, I wrapped a double* coil around the drill shank and then examined the relaxed shape. The legs had to form a 90-degree angle a. The coil had to have a reasonably accurate OD and have a tight 'stack'. It took several tries to get this to come out right, but in the end I was happy with my result. (* My first try duplicated the OE spring by having only a single-wrap coil, but it was too stiff -- I eventually found that a double coil worked better.) Now it was time to bend the tangs onto the ends of wire extending from the freshly formed coil. This easily done in your bench vise, but first you need to know how long to make the legs. It turns out that this doesn't have to be precise. In my case, I made the bend point for the tangs so that the finished length of each leg was 1/2" (measured along the leg, from the tang back to the point where the leg starts as a tangent off of the coil). Make sure that you bend the tangs in the right direction (they should both point outboard relative to the spring coil's centreline). Otherwise, you get to start all over again. Once you form the bends for the tangs, you complete the spring by snipping the excess wire off each tang. The tangs should be at least 1/8" long. Replacement Hinge Pins With the OE pins MIA, I had to make my own. I started with a pan-head 1/8" machine screw, about 1" long. I chucked about 1/2" of the threaded length in my drill press and then used a mill file to reduced the OD of the screw head to about ~ 1/8". With the screw still mounted in the drill press, I then used the file to take the height of the screw head down to ~ 1/8". I now had a cylindrical screw head with a flat top, but with very little slot depth left to accept a screwdriver. I now clamped the screw in my bench vise (using plastic jaw inserts to protect the screw thread) with the screw head sticking out and used a thin hacksaw blade to deepen the slot. Then I reversed the orientation of the screw in the vise jaws so that I could cut off the excess threaded length. The finished length of the resulting hinge pin needs to be ~ 5/8". Get these too long and the heads will stick out of the side of the tray too much and you won't be able to insert the tray into the receiver hole in the console . Get them too short and the pins won't project far enough into the tray to engage the lid's pivot arms. Repairs to the Lid 'Ear' As noted earlier, the ear on one side of the lid (RHS) was had snapped off. I wasn't overly optimistic about just gluing it back in place. It was going to need some structural reinforcement. To achieve this, I marked and drilled 2 sets of opposing 1/16" diameter holes in the ear and the underside of the lid. Short plastic pins were then cut to length and glued in place as part of the overall joining of the ear to the lid. Since the time when I did this repair, Steve Nix at 240Zrubberparts.com has begun offering a replacement lid*. That's probably a safer route to take (January 2020 price is US$100 plus shipping), but my results show that with a little attention to detail these lids can be repaired successfully. (* To the best of my knowledge, no one at this time is offering a replacement tray (tub) as a standalone item. Nor am I aware of any sources for the threaded hinge pins and the little hairpin spring.) Repairs to the Hinge Pin Mounting Bosses As noted earlier, the boss on one side (LHS) was intact but cracked. On the other side, the top of the boss was missing. Although I've always been suspicious of the ability of epoxy-type glues to take much in the way of side loads, they've improved over the years (the JB Weld product lineup is impressive) and I decided to give it a try. Of course, each repair needed to include a threaded hole for the pivot pins. I didn't like my chances for drilling and tapping in epoxy, so I instead did the epoxy repairs with the lid and the pivot pins (but not the spring) in place. The idea was to let the epoxy flow around the pins and their threads. To keep the pins from being glued stationary, I wrapped them with a turn-and-a-half of plumber's teflon tape. After the glue set up, I was pleased to find that - with a little careful coaxing - the pins could be freed up and then screwed in and out within their new epoxy-reinforced homes. That allowed me to adjust the slop out of lid mounting. Installing the New Spring This was a little fiddly. The tray lid needs to be slid over to the right to get enough space to fit the spring tab into the its hole in the lid ear. Then the tab on the other leg of the spring needs to be inserted into its hole in the wall of the tray. This means putting some tension on the spring while also guarding against letting the sharp end of the spring tab scratch the inside wall of the tray. Just takes patience. End Results Unfortunately, I didn't take any in-progress pictures while I was doing these repairs. Hopefully, the finished-result pictures below will provide adequate details. As I write this, the repair was actually done four years ago. I'm pleased to report that all of the epoxy repairs have held up well and the lid still flips open and shut very nicely. The work took me a couple of workshop days and let me direct over $1,000 towards other costs and purchases. If I had the job to do again, I would add a pair of soft-rubber snubbers to the places where the front edge of the lid contacts the inside walls of the tray when it snaps open. I think this is where the parts experience undesirable shock loads and it would be really nice to damp them out. I may just try to insert a couple of strips of adhesive-backed sponge-neoprene sheet in there to make that happen (wish I'd thought of this before I final-assembled the ashtray).

-

Don't have any exploded-view diagrams handy. Is the open-box section at the bottom the pocket for the seat-belt retractor?

- 439 replies

-

- 72 240z

- frame rails

-

(and 1 more)

Tagged with:

-

The diameters for the wire and the drill bit were based on my sometimes flawed memory. You may need to experiment a bit (wire and old drill bits are cheap). I'll try to post a photo of my restored ashtray later today. It had broken in the usual way -- the plastic boss for one of the door hinge pins had failed (perhaps due to the over-aggressive spring tension mentioned in this thread). I rebuilt that area using scrap plastic and JB Weld. After completing the repair, the OE spring looked to me like it was going to overload the area. That's what made me decide to make a low-tension replacement.

-

It's quite easy to make your own low-tension replacement spring. Start with a 12" length of regular (non-tempered) steel wire (stainless preferred), about 1/32" diameter. For a forming device, clamp an old 3/32" drill bit in your bench vise. It should be clamped vertical, with the shank (smooth end) exposed and the cutting end clamped. Now take the length of wire and wrap it ~ 1-3/4 times around the drill bit, so that the two legs form a 90-degree angle when the coiled part of the wire relaxes (it may take you two or three tries before you get the finished angle right). Once you're happy with your result, trim the two legs to the correct length. Remember to form the 90-degree bend on one of the legs before you cut away the excess wire. The lack of temper in the wire won't affect the action of the spring. There's not enough flexure created in the coil or legs to take the wire past its elastic limit. I made my own replacement spring this way several years ago and it still works fine.

-

Especially interesting to see how the hinged arm managed to bend (noticeably) along its long axis. If it was just a flat piece, that would be hard to do. The stamped-in kink near the centre pivot point seems to be the culprit.