Everything posted by beermanpete

-

Intake Backfire:Doing intake & exhaust gasket Exhaust stud busted off flush w/ head

The Heli-Coil will be fine as long as it is installed correctly. Because you end up with steel threads instead of aluminum it will be better than the original threads. The main issue is locating the hole. If you get the pilot drill near enough to the true center you might be able to use a tap for the original thread size and end up with the original threads. If the pilot is off center or at an angle you will need to install the Heli-Coil. Using solvents to clean the back side of the valves should be ok. Remove what you can before installing the manifolds. If significant amounts of solvent go into the cylinder through an open valve you should crank the engine with the plugs removed to prevent any chance of hydraulically locking the engine and bending rods. If the solvent is in the cylinder long enough it could run past the rings into the oil so you should consider changing the oil. You might want to put some oil in the cylinders since the solvent will remove the oil film. Use old plugs at start up as the solvent will likely foul the plugs.

-

Waterpump, alternator, or ???

Despite the danger (real or apparent) the use of a long screwdriver as a stethoscope is common in my experience. A safer tool to use is a stethoscope designed for automotive diagnostic use. Here is an example: http://www.autozone.com/autozone/accessories/OEM-Mechanic-s-stethoscope/_/N-26gd;jsessionid=667EE9C7C8E07AAF4A9687F8649B8E81.diyprod3-b2c13?counter=0&itemIdentifier=70131_0_0_

-

My shifter runneth over -- oil in shifter assembly. Normal?

Driving up and down hills, at various altitudes, extreme weather conditions, etc., are all part of what is considered during the design process. The oil level is set at a point that will accommodate anticipated conditions. This is why the fill plug is located where it is. A sight glass or dipstick would certainly be a useful feature but impractical to implement in the case of many car designs. You fill the gear box until the oil level is even with the bottom of the hole, or nearly so at least. I have worked in automotive and motorcycle service shops and the general practice has always been to fill until the oil is even with the hole. Level checks during routine service involve poking a finger in there to feel for oil. If none is detected it gets oil until it runs out. Precise? No. Suitable? Yes.

-

Is it the Master Cylinder?

Two other things that could cause the same problem are: the adjustment between the MasterVac and the master cylinder and the little bleed hole in the master cylinder is blocked. When checking the pedal free play you should be able to detect 2 distinct points where free play is taken up. The first is the pedal to MasterVac free play; the second is the MasterVac to master cylinder free play.

-

My shifter runneth over -- oil in shifter assembly. Normal?

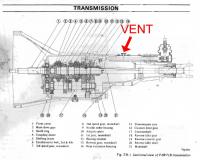

The breather vent is on top of the transmission a few inches forward of the shifter. See the attached diagram. I doubt you will be able to do much with it while the trans is in the car. If the oil was checked/filled while the car was on a service lift the car was most likely level and therefore the oil level is likely correct. My comment about this was thinking that the oil was filled with the rear end on jack stands and the front wheels on the ground which places the trans at angle, raising the check plug in relation to the front of the trans. And yes, you simply fill with oil until it starts to run out at the bottom of the check plug hole.

-

diff fluid

Bonzi Lon, The 1973 Nissan factory service manual, in the differential section, specification section, page PD-12 states, "Oil capacity (about)...". I always fill gear boxes (trans, diff, whatever) to the check plug. If there is a dip-stick I fill until it indicates full. I only use the capacity specification to determine how much oil to buy. Running the engine, gear box, or differential with slightly less or more oil is not a big deal anyhow. It only matters when the oil level is so low that it overheats or cannot properly lubricate the bearings, or if the oil level is so high that the oil foams or expands until it flows out the breather. In between these two extremes it is not terribly important exactly how much oil is in there.

-

diff fluid

The differential and transmission should always be filled until the oil level is even with the check plug bore. The oil capacity listed in the manual is approximate and is for reference only.

-

My shifter runneth over -- oil in shifter assembly. Normal?

It does seem like it should but the shaft is horizontal, or nearly so. Any oil that gets on the shaft from oil sling or vapor condensation could (and apparently does) run to the back of the shaft. The striking guide has a pocket in it that will allow the oil to puddle rather than run back into the gear box when the car is parked. Also, the seal will attempt to prevent oil from going past it in both directions (as it should). There are several forces at play trying to push oil out and only gravity trying to push it back in. Make sure the oil level is correct, an over-full condition will aggravate the problem. Check the oil with the car level. Don't lift only one end of the car when crawling under there to check the oil. Another contributor to oil in places it might not normally go is a blocked vent. Check the breather vent for free flow. If it is blocked pressure will build in the transmission as it heats pushing oil out anywhere is can manage to flow.

-

No fluid getting to rear brakes

The emergency switch (pressure differential switch) is suppose to reset itself upon correcting the problem that caused the imbalance in the pressure. It has been mentioned in other posts on this subject that it is capable of blocking, or at least restricting, the flow of brake fluid. I doubt that it would because that would interfere with bleeding the brakes.

-

My shifter runneth over -- oil in shifter assembly. Normal?

The shifter is sealed from the gear box. It should not have 90W in it. You probably have a bad seal on the striking shaft. See the diagrams in the service manual.

-

No fluid getting to rear brakes

Directly below the master cylinder, attached to the inner fender. It has 5 brake lines and 1 wire attached to it.

-

No fluid getting to rear brakes

It sounds like your master cylinder is bad. It has two circuits, one for the front and one for the rear. Inside the master there are two pistons, one for each circuit. The "first" piston is connected to the brake pedal via a push rod. When you push the brake pedal the piston is pushed forward and creates pressure in the cylinder. The second piston is pushed by the pressure created by the first piston. The brake pedal stops moving when the pressure in both systems is high enough to push all the brake pads and shoes into the rotors and drums. If the first piston does not create pressure it will move until it physically touches the second piston. When this happens the second piston begins to move and create pressure. If the second piston does not create pressure (but the first one does) it will move until if bottoms out in the cylinder and stop, at which point the first piston will create pressure. In either of these cases the brake pedal moves futher, about 1/2 way to the floor, before the pads or shoes for the functioning system are pushed into the rotors or drums. Try bleeding the master cylinder. If you cannot get fluid to flow from both the front and rear circuits the master is bad.

-

Gauge I.D.

They both look the same as the meters from my 73.

-

Best Place to Tow a Z

We tow our 73 240Z by the bumper brackets without any problem. They are pretty beefy looking. Perhaps the 72 is not as strong? We removed the bumper and drilled new bolt holes in the brackets to attach the clevises for the tow bar. If you want to tow the car without any mods then the dolly is probably better and easier.

-

new to z need some help with experience z owners! please

It is not an absolute requirement to change both at the same time. However, it is a good idea because it is common for one to fail soon after the other.

-

need help please - engine died will not start - i am at wits end

I agree with Zed Head. Check the resistance of the pick-up coil with an ohmmeter. Look in the service manual for the year model your distributor is from. It will have a specification for the DC resistance of the coil.

-

new to z need some help with experience z owners! please

Yes, the clutch master cylinder is the furthest to the driver's side. Add some brake fluid. It should help, at least temporarily. You seem to have identified a leak at the slave cylinder (on passenger side, near the starter). To fix the leak you will need to replace the slave cylinder. You should also replace the (clutch) master cylinder at the same time.

-

Slight Groove In Cylinder Wall

From what I can see in your photo it looks too deep to clean up with honing. Either way you need to do a full tear down. At that point you should do as Walter suggested and let a machine shop inspect the block and render an opinion.

-

Mid Range RPM Hesitation

If your problem is fuel related it is more likley from poor fuel flow rather than float level adjustment. You should check all the fuel filters. The main filter in the fender of course and the screens in the fuel inlet to each carb (in your favorite float bowl covers). If there is no problem with the filters perform a fuel flow rate test (capacity test) as instructed in the service manual.

-

73 240z rear drums won't bleed.

Hurray!! Success!

-

Draining Brake Fluid

Yes. The procedure is the same as bleeding the wheel cylinders except you are working at the master.

-

73 240z rear drums won't bleed.

Have you had the adjuster out of the wheel cylinder to clean and lube the threads? Perhaps it is full of dirt, rust, or other foriegn matter that is binding the threads. If not, do so. When you put if back together leave the adjuster out near last few threads so the shoes are at the maximum diameter. If you can still put the drum on you have a problem with the parts or assembly.

-

Tokico Coil Springs - Is this right??

We have Tokico springs on our 73. I do not recall the part number but they are whatever Tokico sells as a 240Z spring for the early 1973 model. All are loose at full droop with about 1/2" or so of gap between the spring and the spring seats. With the car on the ground (at rest) there is only about 1 1/2" of bump travel to the bump stops.

-

73 240z rear drums won't bleed.

Also, make sure the brake shoes are adjusted to be close to the drums. You should be able to detect a little drag here and there as you turn the drums by hand. If they are too loose it will cause a low pedal.

- Weird compression test results