Everything posted by Patcon

-

Vapor Tank Question

Then the vapor tank is cracked or you have hoses that are leaking. If your vapor tank is metal then you can tighten the hose clamps with no fear...

-

Vapor Tank Question

Or you smell gas from another source, not the canister...

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

30 amps is alot of Draw. Any ideas?

-

ZCCW Maryhill Loops Drive 2024

Looks like fun!

-

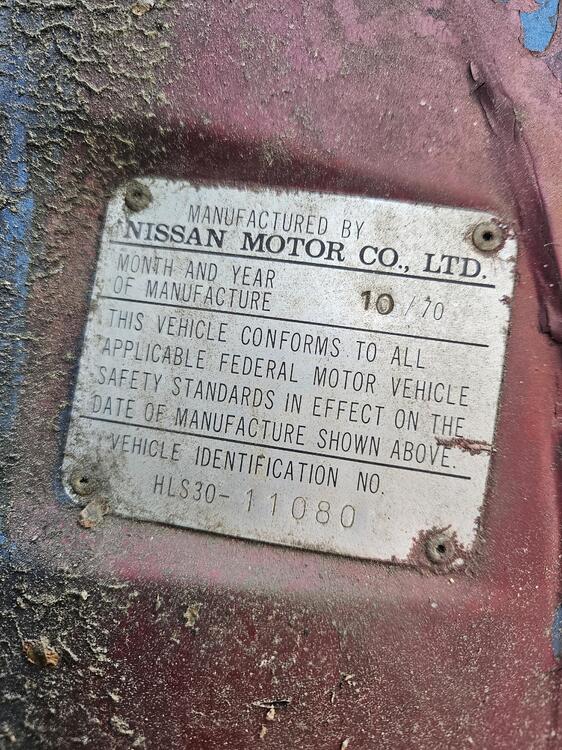

HLS30-00684

It's #684! A potentially valuable car. Plenty of donors available for upper area metal. I would try to save it, if I could, based on Vin number alone. If the A pillars, roof structure and most of the firewall was good, I would probably give it a shot. It would also be nice if the tunnel was good down to where the floor pans would meet it. I would probably want to dip that chassis before the final decision got made I've got one worse than that in the driveway. The rusty one I have is beyond saving but it's also not a super early car

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

It takes a long time to not feel tired after Covid. Which way are you cutting the walls? Cutting the corner brown in or cutting the siding color back against corner. I would typically paint the corners and then cut the siding color in. I find that easier

-

Seat Belt Release Access Solution

Love the seats! Love the console! And seat heaters?? More info please, maybe in the 510 section?

-

Conflicting info on Voltage Regulator delete wiring

@SteveJ

-

Advice on selling Mikunis

I would think they would be worth more than $900. I would suspect more in the $2,000 range based on this https://www.ebay.com/sch/i.html?_from=R40&_nkw=datsun+mikuni&_sacat=0&LH_Sold=1&LH_Complete=1&_sop=16

- 240Z SU Throttle Cable Kit

-

Which Oil Pan Will Fit?

What did you do for the muffler? How does the race header compare to Sean's other headers?

-

MZR

Depends on the RB. An RB26 was about 276BHp stock. They can make in the 400's. Supposedly about 500 HP things start to break internally

-

MZR

I tried to find current pricing. The sport design was about $97,000 The evolution was starting in the $232,000 range. I suspect those numbers have gone up recently. I'm not a huge fan of the carbon fiber exterior. I have thoughts like bonding strength. Fatigue over time and how does the unit work as a whole. Layup orientation and weave. Ease of repair. Etc. I get there is some weight savings but is seems like a little more horsepower would overcome the excess weight easier than reskinning the car. Cody wants to build a crazy S30 RB powered car. I would think an RB powered MZR would be a good option if you stayed with the all metal car. I know they are working on an RB car. There would be a cost premium but even DIY it wouldn't be a cheap build. The MZR might also retain value better because of the name recognition

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Thanks for the tip. Just ordered some. It's amazing how expensive so many of these items have gotten

-

anti backfire valve

Valve adjustment would also be low hanging fruit

- MZR

-

Datsun-240z Vs Fairlady-z432

That's all great progress. The plating looks really good! In almost 40 years I don't think I've ever take the exhaust manifold/down pipe joint loose without breaking at least one of those studs.

-

How to remove clutch pedal pin??

Take a picture of what you really have. I have never seen one welded in place

-

1971 HLS30-14938 "Lily" build

I don't know. Maybe somebody with a more complete parts database will chime in. It would be nice to know but for now it appears to be an original harness in a car a month earlier than Lily. The brown z was my daily driver 30 years ago, so I should be able to get Lily going with the donations

-

Can you bleed clutch without lifting car?

Yes, it can probably be done from the top. Easier with two people though. The clutch isn't as sensitive to air bubbles as the brakes are. Get most of the air out. Make sure you have good clutch lever movement. Make sure it changes gears properly once it's running.

-

1971 HLS30-14938 "Lily" build

Fascinating, it looks like it's got a 9/70 manufacture date. The Exx50 makes me wonder if it was a small revision somehow?

-

1971 HLS30-14938 "Lily" build

So I need someone with the factory parts book to check something for me. I looked on car parts manual but they don't show a corresponding number for these dash harnesses. They are close to the early car dash numbers but not exactly the same. 24013-E4650 & 24013-4651

-

1971 HLS30-14938 "Lily" build

I think I am going to take the ignition switch and combo switch all together since I know where that ignition key is 🙂 I have a 5 speed that I took out of the brown Z that will go into Lily. Haven't really ever taken the time to ID it

-

1971 HLS30-14938 "Lily" build

I saw atleast one of those today. I will look tomorrow and check car parts manual. I was hoping the same thing based on the 140psi gauge. Although the cigarette lighter location makes me wonder. PS my daughter gets married next weekend in Ohio. I hope to have time to come visit shortly after that

-

1971 HLS30-14938 "Lily" build

So later dash in an early car? This is in the "Brown Z" Cody had suggested a great plan. Cannibalize the Brown Z for the dash harness I need and anything else so I can get Lily done for now. They are only a month apart. But I saw the dash and hazard label and then I started wondering what was what?

Subscriber

Subscriber