Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

I think I am going to take the ignition switch and combo switch all together since I know where that ignition key is 🙂 I have a 5 speed that I took out of the brown Z that will go into Lily. Haven't really ever taken the time to ID it

-

1971 HLS30-14938 "Lily" build

I saw atleast one of those today. I will look tomorrow and check car parts manual. I was hoping the same thing based on the 140psi gauge. Although the cigarette lighter location makes me wonder. PS my daughter gets married next weekend in Ohio. I hope to have time to come visit shortly after that

-

1971 HLS30-14938 "Lily" build

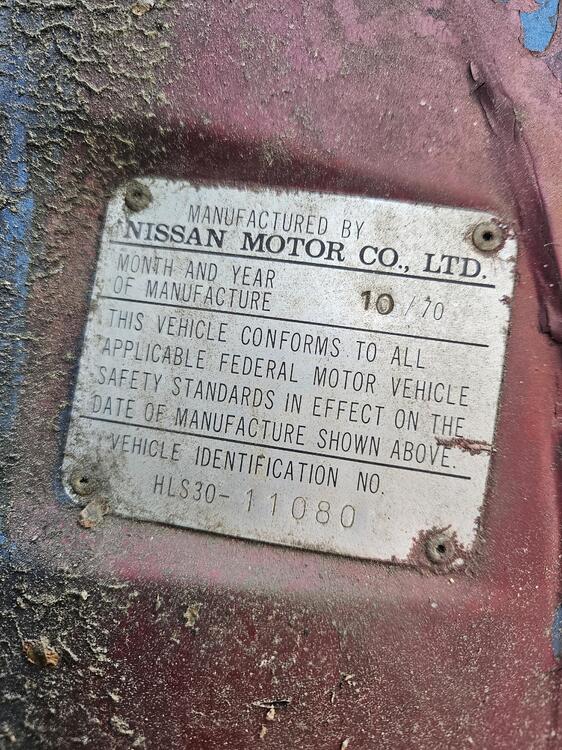

So later dash in an early car? This is in the "Brown Z" Cody had suggested a great plan. Cannibalize the Brown Z for the dash harness I need and anything else so I can get Lily done for now. They are only a month apart. But I saw the dash and hazard label and then I started wondering what was what?

-

1971 HLS30-14938 "Lily" build

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

I like the spot weld cutters like this or this I do not like this style A little oil helps. Be careful with the bit corners, they are brittle and easily damaged. Constant pressure helps. The carbide or specialty coated ones last a lot longer. My tool of choice for spot welds is a die grinder with one of these That section of the frame is pretty stout. It's thicker than a lot of other areas of the car

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

I would drill out the spot welds if possible. I would think that would be the best method for the most invisible repair

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Ideally, you would remove the whole tower and replace it. Or you could just move the center mount of the shock tower and patch in the metal around it to make it look right

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

It would be pretty easy to make those shock towers stock again. Provided you know how to MIG. Just make sure you get the front end on level and square. A frame rack would be best for that

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Holes can be welded up...

-

My 240z that's been sitting

Just the remember the float bowl hoses are unique. They are not standard fuel line. They are softer and more flexible

-

Machine work on SU for roller bearings

So is the throttle shaft a custom part too?

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

I think the upper frame rail at the hood hinges is available as a repop. I don't think the front inner fender area at the radiator support is available but KF vintage might make it if asked

-

1986 300zx detonation sensor question (running a 86 ecu on a 280zx turbo engine).

All of that is above my "paygrade" 😉

-

73 240z won’t start. Have spark

@Zed Head you've done great. Very patient, very tenacious!

-

73 240z won’t start. Have spark

I may be missing something but both cam lobes on #1 don't appear to be up in that picture...

-

Restoration of BringaTrailer 240z - HLS30-35883

Where's my build thread for Mr. Rusty???

-

L28 NA N42 Engine (Block and head)

Radiator cap could also be weak. Not holding proper system pressure

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I reused my mainshaft nut. Many times they don't end up in the exact same orientation after torquing with new parts. So you're peening down a fresh section. I believe the LH(?) thread ones are NLA. Some people have machined batches in the past and made them available to the forum.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I used black rtv

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I don't use the search feature on the forum. I use a Google search and use "site:classiczcars.com" at the end. It will crawl this site alone for results. I get better results this way

-

1971 HLS30-14938 "Lily" build

I believe it was the really early cars, like pre 9/70. I believe my car is later than that

-

1971 HLS30-14938 "Lily" build

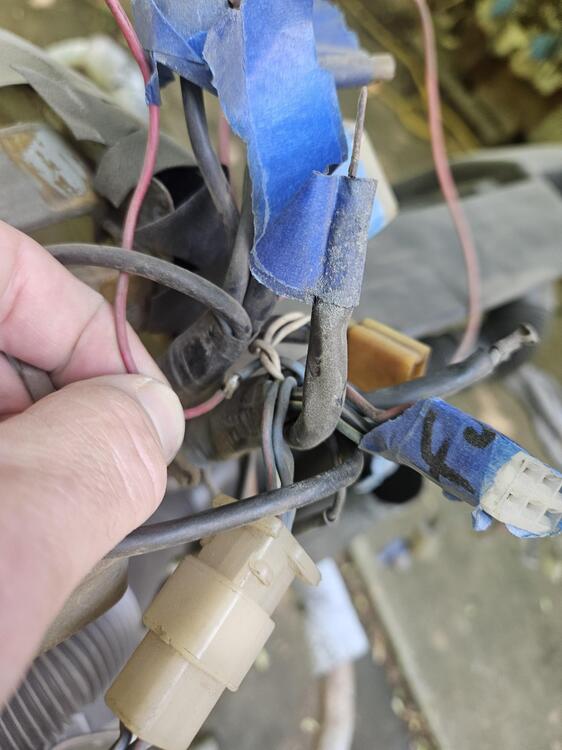

Now for my next challenge is the dash harness. I'm really starting to dislike PO'ers. The dash harness has lots of hacks in it. There appear to be 3 different dash harness from 9/70 - sometime in 71. I have other dashes I could use harnesses from but I don't know if they would work. Can anyone give me details on what changed and how hard adapting a 71 dash harness would be?

-

1971 HLS30-14938 "Lily" build

-

1971 HLS30-14938 "Lily" build

Yeah, I don't know what month that changed during production

Subscriber

Subscriber