Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

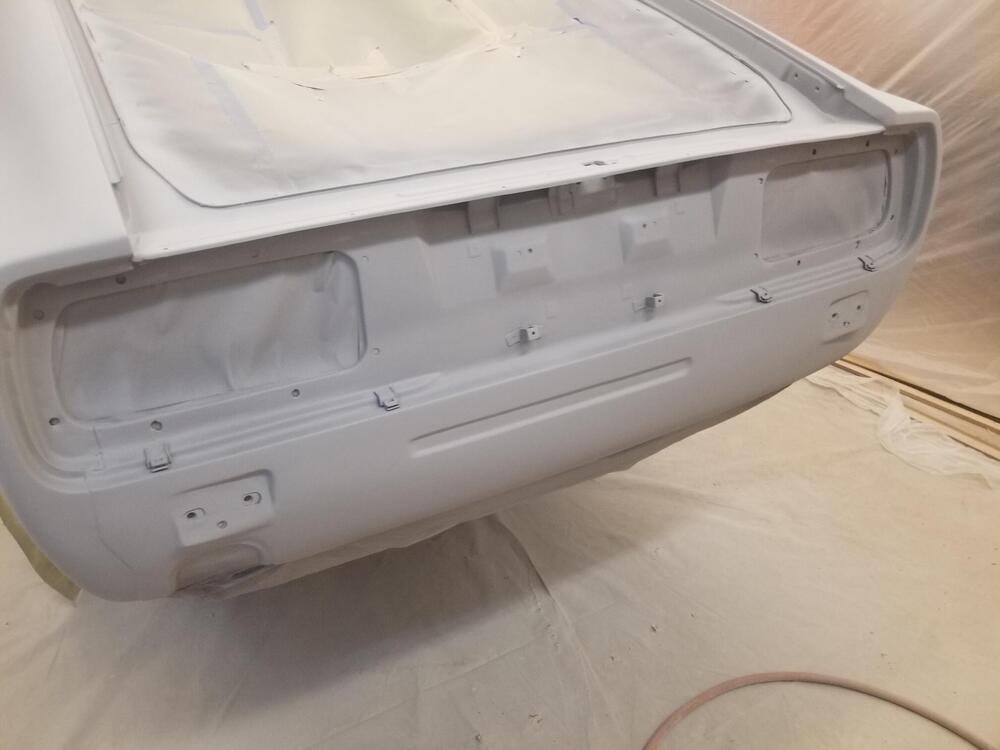

Stacked some high build right before supper. Hopefully it will block out pretty close without needing too much more work

-

1971 HLS30-14938 "Lily" build

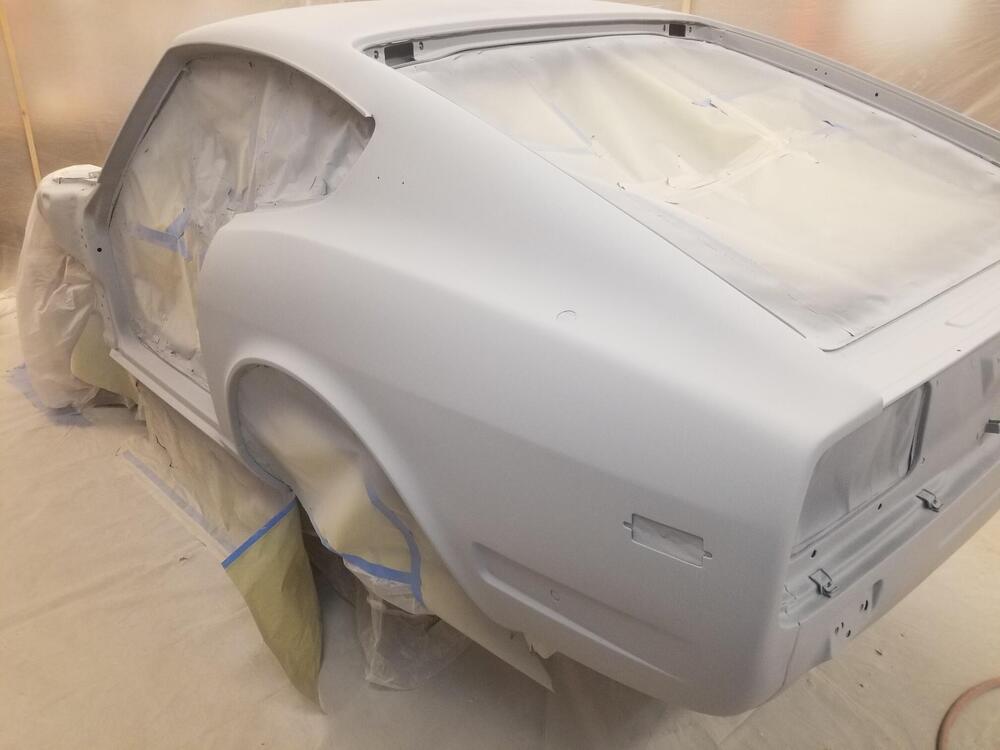

So I finally got the car sanded down as far as I was willing to go. I taped it all up over the last week or so and reset the booth. Then shot some SPI white epoxy over that. It's a little different than what I am familiar with. It will fish eye if you lay the first coat on too heavy. Being white it can be hard to get full hiding coverage. I may stack some high build tomorrow. I've got 7 days to coat. We'll see...

-

Oversize Pistons

I always like to source pistons before machine work for this very reason...

-

Scarab Parts Car (Craiglist)

Pretty rusty! I'm not sure it's a true "Scarab"...

-

Science!/Not science! Unsticking stuck parts

Acid for the win. I wonder if it causes any issues with the aluminum pistons?

-

Oversize Pistons

Pistons normally come with wrist pins either press in or fully floating. If they're press in you should have the machine shop install the rods. They have a special oven to heat the rod so the pin presses on easily

-

Correct fasteners for Intake and Exhaust Manifolds

Haven't seen him around in a long time...

-

Bad noises somewhere in my drive train

Im with Jonbill, open the diff up for a look

-

1973 240z Custom Wiring From Scratch

Yes, that is normally true of this type of wiring diagram

-

1970 240Z Works Rally - the road to restoration

That makes for a valuable piece of glass!!

-

My two swiss S30Z Fairlady Restoration build thread

Ebay ad link? Who supplied the harness tabs?

-

1977, 280z with FS5W71B transmission

Do you know what they call the guy who graduates last in his medical class? Doctor... 😉 No offense to conedoger 🙂

-

L20b Cody's Goon

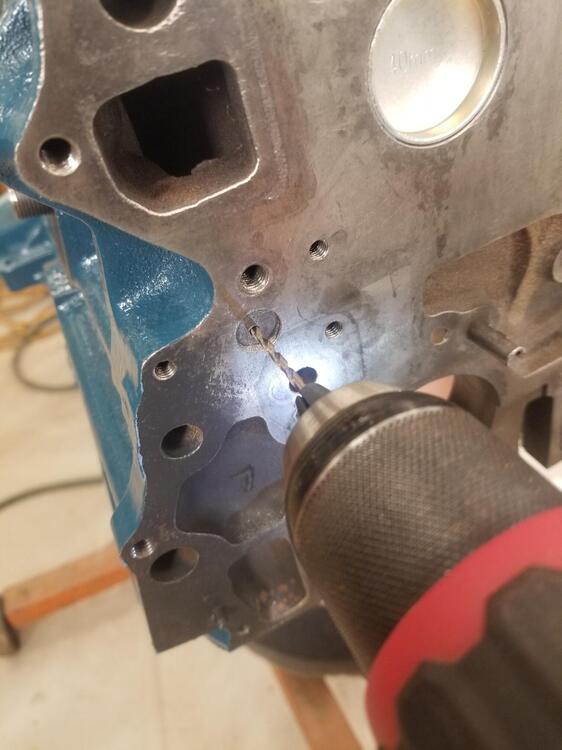

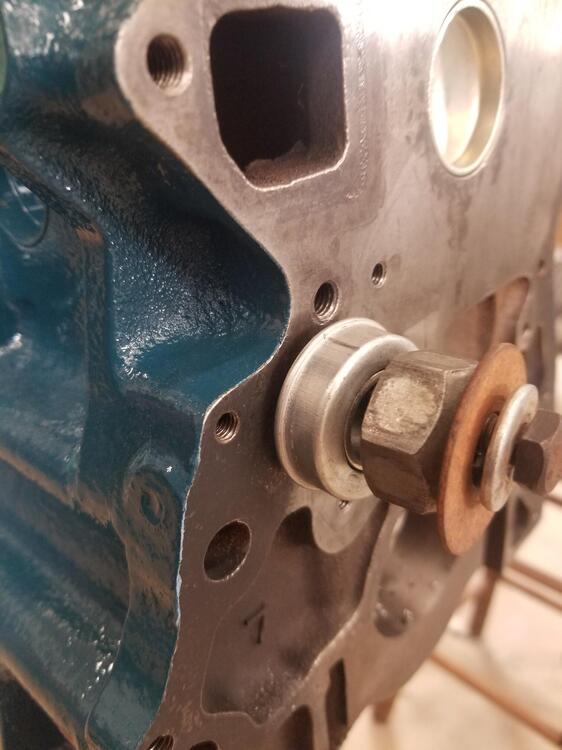

So we had to rework the end of the oil galleys. The holes we had drilled and tapped weren't big enough for a 3/8 plug. So I found a 9/16 bit; it called for 27/64 and we drilled them again and tapped them. You have to drill them and tap them pretty deep so the plug will go in flush. You can see one of the feed holes in the threading. the plug doesn't actually go in that far. We measured for clearance.

- L20b Cody's Goon

-

1983 280zx turbo engine

Lookong forward to this! I have 2 L28ET's here in the shop

-

Her Majesty the 26th

Bradenton, thats Cleetus territory 😎

-

Engine Oil 10W-40 vs 20W-50 in L28

I probably wouldn't go 20 weight unless my oil pressure seemed really low or I had knocking

-

slight exhaust popping and low power ......

Many times popping is excess fuel lighting off inside the hot exhaust system. Poor ignition or too much full. Plug gap in the new plugs could be an issue depending on your particular ignition system

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

Should have a drain plug...?

- 280zx 1979 2+2 slick roof restauration

-

Clutch Won't Disengage

I wonder if the pushrod adjustment at the master would change the slave travel?

- Just saying hello

-

L20b Cody's Goon

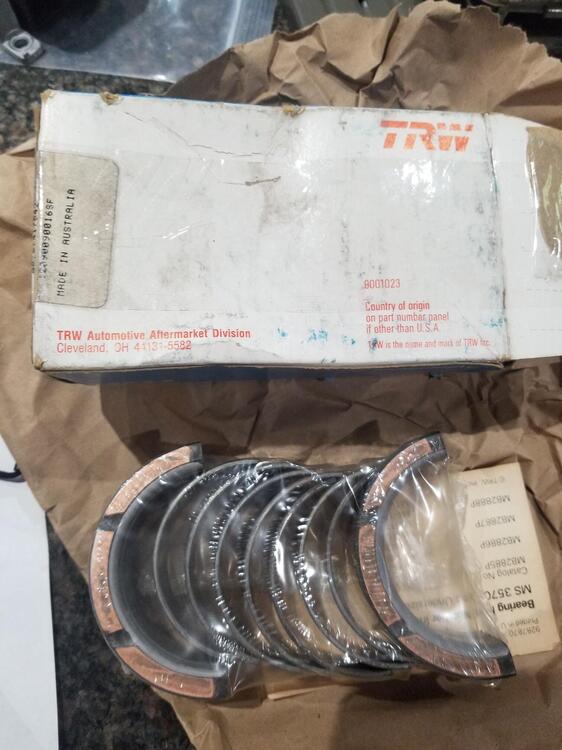

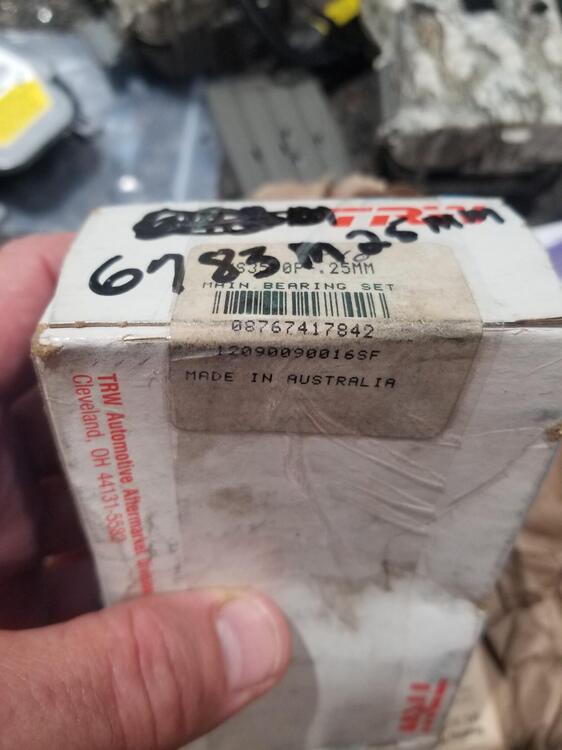

So let’s see about a little update: Cody and I started working on his motor maybe a week ago or so We had to decide if we were going to drill the mains out or just slot the block side of the main cap and add a feed hole in the bearing. I looked in Honsowetz’s book and he recommends opening those feed galleys up to 5/16 or 0.313”. Which if I calculated it right is a 62% increase. So Cody and I discussed it and felt more comfortable with drilling the mains. Partly because we’re not making a lot of grit in the engine block. We started by getting the end plugs out of the main galleys. That way we could properly clean and wash the block later. They were stouter then I expected… A little homemade puller big enough for the plug to pass through it We didn’t want to drill the supply mains and realize we couldn't get the main galley open to clean it out. Then we worked on tapping the ends of the main galley for brass plugs We may have to make these deeper but I didn’t want to make them too large since the 3/8 NPT tap is tapered. On to drilling… So this is really sketchy because the metal drills pretty easily but only the very edges of the bit are cutting. We used 3 different sized bits to work up to 5/16”. They didn’t need to be special because you’re not drilling overly deep. We were concerned we might break a bit but with a little cutting oil it went pretty good. We were going to clean the block up and get ready for setting the rotating assembly but I can’t find the main bearings I bought! I went by the machine shop last Tuesday and he didn’t have them. Even though I’m pretty sure I took them, but I can’t be sure I didn’t pick them up. The problem is, right now they seem to be unavailable everywhere. Neither Clevite or King. I found some vintage TRW’s on ebay I have coming my way and I have an order in for some Kings from another place. Hopefully one of them will get here soon. Cody would like to have a running car by Zcon. He will have to hustle! It’s doable but he will have to focus to get it done.

-

Shifter Rattle

The 23t idler can be difficult to locate. I was fortunate a forum member helped me out with a used one

-

Clutch Won't Disengage

If the clutch plate is slightly off center then the transmission input shaft is not centered and has an interference fit with the pilot bushing. When using a centering tool, sometimes you need to lift it slightly to counteract gravity.

Subscriber

Subscriber