Everything posted by Patcon

-

slight exhaust popping and low power ......

Many times popping is excess fuel lighting off inside the hot exhaust system. Poor ignition or too much full. Plug gap in the new plugs could be an issue depending on your particular ignition system

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

Should have a drain plug...?

- 280zx 1979 2+2 slick roof restauration

-

Clutch Won't Disengage

I wonder if the pushrod adjustment at the master would change the slave travel?

- Just saying hello

-

L20b Cody's Goon

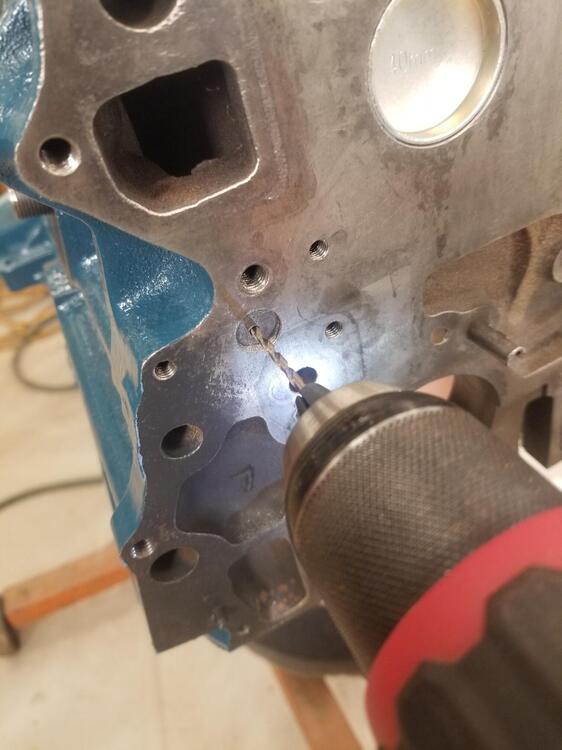

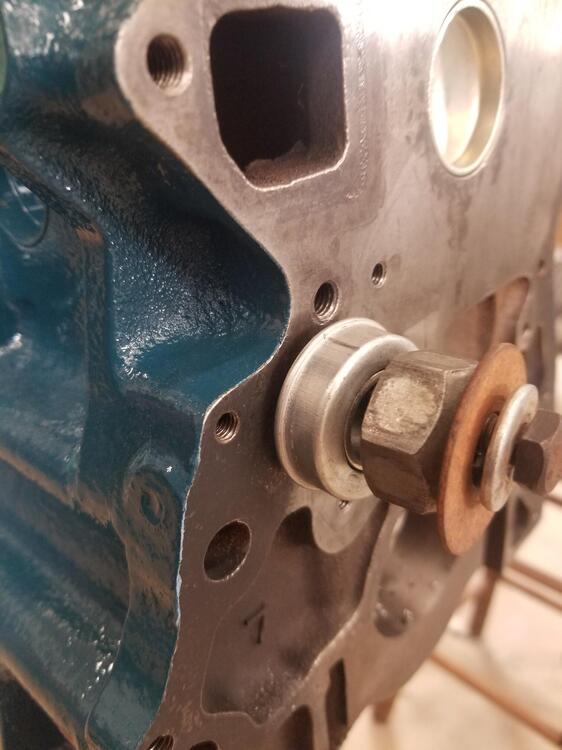

So let’s see about a little update: Cody and I started working on his motor maybe a week ago or so We had to decide if we were going to drill the mains out or just slot the block side of the main cap and add a feed hole in the bearing. I looked in Honsowetz’s book and he recommends opening those feed galleys up to 5/16 or 0.313”. Which if I calculated it right is a 62% increase. So Cody and I discussed it and felt more comfortable with drilling the mains. Partly because we’re not making a lot of grit in the engine block. We started by getting the end plugs out of the main galleys. That way we could properly clean and wash the block later. They were stouter then I expected… A little homemade puller big enough for the plug to pass through it We didn’t want to drill the supply mains and realize we couldn't get the main galley open to clean it out. Then we worked on tapping the ends of the main galley for brass plugs We may have to make these deeper but I didn’t want to make them too large since the 3/8 NPT tap is tapered. On to drilling… So this is really sketchy because the metal drills pretty easily but only the very edges of the bit are cutting. We used 3 different sized bits to work up to 5/16”. They didn’t need to be special because you’re not drilling overly deep. We were concerned we might break a bit but with a little cutting oil it went pretty good. We were going to clean the block up and get ready for setting the rotating assembly but I can’t find the main bearings I bought! I went by the machine shop last Tuesday and he didn’t have them. Even though I’m pretty sure I took them, but I can’t be sure I didn’t pick them up. The problem is, right now they seem to be unavailable everywhere. Neither Clevite or King. I found some vintage TRW’s on ebay I have coming my way and I have an order in for some Kings from another place. Hopefully one of them will get here soon. Cody would like to have a running car by Zcon. He will have to hustle! It’s doable but he will have to focus to get it done.

-

Shifter Rattle

The 23t idler can be difficult to locate. I was fortunate a forum member helped me out with a used one

-

Clutch Won't Disengage

If the clutch plate is slightly off center then the transmission input shaft is not centered and has an interference fit with the pilot bushing. When using a centering tool, sometimes you need to lift it slightly to counteract gravity.

-

[2022] What Did You Do To/with Your Z Today?

Looks great!

-

Z's on BAT and other places collection

Pretty car!

-

Clutch Won't Disengage

Are you sure it's bled properly?

-

L28ET need help with turbocharger looking for OE fitment and performance.

How hard it is to replace the turbo cartridge and get it clocked right? I once tried to disassemble a turbo and found the bolts to be quite persistent!

-

L28ET need help with turbocharger looking for OE fitment and performance.

One detail I didn't see in any of the ads was what wheels were on either end and what the spec was for the factory wheels

-

Not quite overheating

If I were going to try to flush a block out. Take the head off and use a prressure washer through the top of the deck and the water pump holes. Messy but you'll be amazed at what comes out.

-

What is normal oil pressure indications?

I had a Z once that read low like that. I rigged up a mechanical gauge under the hood. It was actually much higher than indicated. It's a common issue

-

240z mechanic in KC

Sorry to here that! Maybe we have a member in the area who can recommend someone

-

MSA 6-1 Header Install

The old coolant looked a little bit rusty?

-

Not quite overheating

If you are having coolant blockage issues. You might be able to flush it out with the head off. Many times the cylinder head gaskets have some small holes in them. Maybe some of these are getting blocked. Maybe even temporarily.

-

Another SU high idle thread

Blue loktite or stake them. You have to support the throttle shaft to stake them or they wil bend. It a tricky process

-

Parts Wanted: Looking for a interior light lens for a 1975 Datsun 280Z ?

The assembly comes out pretty easily. As I recall it just pulls out and has two spade plugs to disconnect

-

Another SU high idle thread

Are the throttle shaft screws staked? It is possible to ingest those if they were to back out, but staking must be done with care...

-

Z's on BAT and other places collection

That was probably a really good buy

-

Parts Wanted: Looking for a interior light lens for a 1975 Datsun 280Z ?

They are hand made, one at a time. The color does seem off but Steve is very obsessive about making accurate reproductions. I feel confident the color is correct. He would be my first choice if you can figure out shipping.

-

L28 normal noise, excessive valvetrain noise, or exhaust leak tick?

Have you asked Eiji about running 40w oil?

-

Parts Wanted: Looking for a interior light lens for a 1975 Datsun 280Z ?

https://www.240zrubberparts.com/apps/webstore/products/show/4525381

Subscriber

Subscriber