Everything posted by Patcon

-

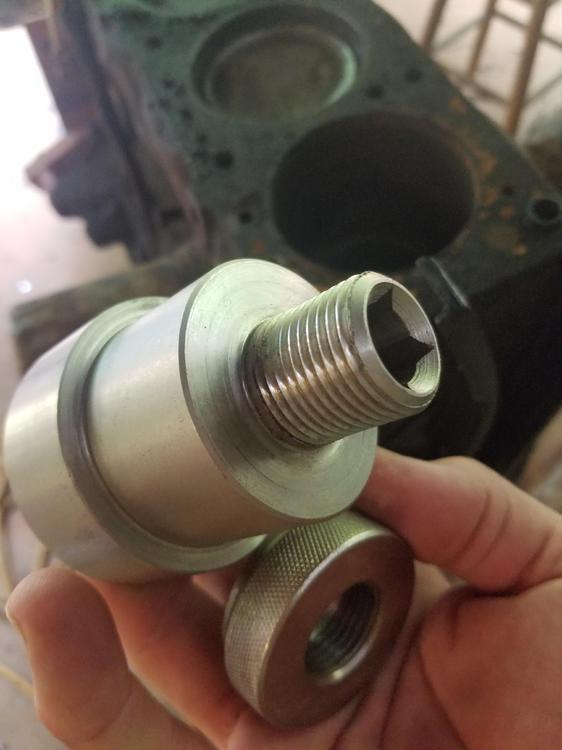

Crank snout turning nut

Shelley had a 1/2" piece of glass in the bottom of her foot for several weeks and even went for a six mile hike, not knowing it. Crazy! The thorn should get pushed out in a few days

-

Crank snout turning nut

Take some Dawn dish detergent to the shower and scrub real good and most of the oil will come off. We went hiking in a very heavy poison ivy area last weekend and so far all is good.

-

Info needed for Series 1 240Z

Some of that is semantics. I would consider anything under 5000 an early car. As the number of those out there are dwindling. Some would consider under 500 an early car. I tend to refer to those as "very" early cars. They have lots of anomalies and are all 1969 cars I believe

-

Crank snout turning nut

Actually it didn't take a trememndous amount of force to pop the damper. Maybe 20-25#s. That is why I suspect the damper was already cracked. That seemed a little too easy. I am hoping to get it free enough to run it short term. We'll see. It's sort of a short term solution to a long term problem. If I start taking it apart to get it free, it expands everywhere and we have to start the engine build right away, with my funds not Cody's. Also it's an L20b so only four cylinders. I have pounded on the pistons some and believe I have the corrosion broken loose. It's just a matter of gaining access to new ground for cleaning up. This engine still has the oil pan on it I believe. I am not too worried about wiping the flats. The weak link is really the engine stand and bolts. I have to put teenagers on all three points to hold it down in order to pull on it. I may chain it down next time but the stand bracket and block bolts will eventually be the weak link if too much muscle is used As an aside I am about 230# all fitted out. So I can exert some pressure even through the 2' crescent wrench. If that won't get some movement it will be time to reevaluate. Another comment. One of the problems of going from the flywheel end is there is very little room between the flywheel and the engine stand for tools or bars and there are 4 bolt locations so you are very limited in rotational freedom

-

Underside OEM Finish's

I had planned on blacking that lip out also. I can be a "little" compulsive too...

-

Grease gun Shopping

If you have battery tools, consider getting a battery powered gun. I have a nice Dewalt one and wouldn't dream of going back to a manual grease gun

-

Info needed for Series 1 240Z

You might be able to see the badge holes from inside the panel with the interior plastic removed. Depends how well they did deleting them

-

Crank snout turning nut

Don't really have a good setup to rig that up and I'm not sure a starter would do it. I think this will be a battle of mm's to start with. If I can get it to move some. I can use a bore hone to clean it up and get it all the way free. Just need enough leverage

-

Info needed for Series 1 240Z

I would be inclined to believe they were deleted by a previous owner

-

Crank snout turning nut

Looks like 1.891" This is the result of the damper and about 5' of pipe welded to it. You can see the pipe under my hand. Although the damper could have already been damaged from the PO

-

Crank snout turning nut

Interesting thought but I am not sure that would work that great. The crank gear is really not that thick when measure at the bottom of the grooves. Even thinner at the keyway. i already popped the balancer open that we had welded an arm to. Plus if yo grind flats, you will have to grind pretty deep to get a reasonable surface for the wrench to bear against. Now on an unfrozen motor, it would probably work fine. Although I would not want the press fit of the gear

-

[2020] What Did You Do To/with Your Z Today?

I would really like to have the delay wiper they had on the 73's if I do the upgrade...

-

[2020] What Did You Do To/with Your Z Today?

Jim, This give you 2 speeds like original correct? C

-

Look at my car, tell me what you think.

As a counter point. I would not be afraid to lift the car the way they did as long as the pad is on the thicker part of the frame rail at the fire wall. Not under the floor or floor rails! Also the pads need to be nice and flat. The cross member is even better but not everyone has access to a four post lift

-

Crank snout turning nut

-

77 280z timing problem ***NEED HELP***

Good link Site The short answer is the turbo cam is not going to breath as well in a NA engine. the added pressure makes up for lack of valve lift and other small changes

-

77 280z timing problem ***NEED HELP***

Visually? or verified with some calipers and degree wheel?

-

Crank snout turning nut

Looks like the depth is less than 0.100" on several of the cranks that I looked at Two flats is fine, if that's easiest

-

14 Project Zs For Sale - Includes Six 240Zs on Craigslist Spokane

See, Im not a hoarder!!

- Crank snout turning nut

-

Crank snout turning nut

I am not sure aluminum will be strong enough. Pretty sure it's steel because it weighs a couple of pounds Expound on your mic interpretation I figured it a 1-2" mic so by default 1.something little hashes put it 1.3... approximately 3/4 makes it 1.37 Then 3 marks past zero makes it 1.373, correct?

-

Quality 240Z Floor Pans & Frame Rails Finally Available

@kfvintagejdm A nice panel that needs reproduction is an accurate battery tray and a section of the wheel well below it

-

300zx cv axle rebuild

So I have been working on rebuilding some cv halfshafts that I have with an CLSD differential This is the second one with the bands cut. One of the shafts, the boots were split and I can't imagine the grease was supposed to be tan. Normally that is an indication of water but maybe the factory grease was tan. You need to mark the one end (outer end) that can be disassembled. Supposedly the inner end is not disassemblable. So I made small marks and also marked some blue tape for indexing Then you drive the cap off the end Then remove the snap ring and use the puller There is a clip on the inboard side too I could not find a way to disassemble this end So the inner boots are NLA at Nissan and I could not locate them any where else. Dorman makes a "Uni-boot" that has multiple applications and needs to be trimmed to fit. Also the inner ones are light grey. I just couldn't do that! So I found outer boots on Rockauto that match the factory boots pretty good. For the inner boot, I found that generic boots were available on Ebay if you know how to search for the right size. So I found some boots that looked correct. The right size, the right number of ribs, but surprise! They have three nubs molded on the inside, I was not expecting So I got the die grinder and removed them Here is the first shaft next to the next one

-

Cody's Goon

11/23/2019 back from paint jail Left on 3/4/2019 for a 4 week paint job... We have gone around a couple of times to get him moving on it again. He is finally starting to work on a few weeks ago. He has some doors partially assembled and on the car and it's at the trim shop for a headliner currently I told him he needed to get going and finish it or I would pay him for what he's in the car and keep it for myself. Tired of it taking up premium space around the shop! He's really very close and could have the car running in just a few weeks if he got serious about it

-

Crank snout turning nut

@Captain Obvious So I received the new tool. Short story is it won't work! The internal Id they said was much closer than it is. Also the internal shape is all wrong. So back it will go It would have been nice if it had worked because it will accept a degree wheel under the knurled nut So I need a device with an Id like this I believe that 1.373" with a key way that .205" wide As an aside the LD28 crank sitting on another bench has the same snout OD. So this tool should work on pretty much everything L series

Subscriber

Subscriber