Everything posted by Patcon

-

NOS door panels (Not mine) in Seattle.

Good for him! That was a good price.

-

Bad Air Pump Valve?

Options: You could source another manifold and galley - not too hard to install Replacing the galley is very difficult unless you have an oxy/acetylene setup. They basically weld themselves into the exhaust manifold over time Remove the manifold and cut the galley and seal up the holes. I did this 30 years ago with mixed results Or you could go all bling and order one of Sean's stainless exhaust systems. Header all the way out... You shouldn't damage the motor with the exhaust leak but you can melt stuff from the heat of the leak blowing on things under the hood.

-

NOS door panels (Not mine) in Seattle.

That's probably a good price for NOS door panels

-

1971 HLS30-14938 "Lily" build

I don't mind the clear lens and it came from a friend. So it will be proudly displayed in the engine bay. 😉

-

Still struggling with car at idle after 8 years

Is the car hard to start when it's cold?? If not, then there's not a problem!! If it's not broken, don't break it!

-

1971 HLS30-14938 "Lily" build

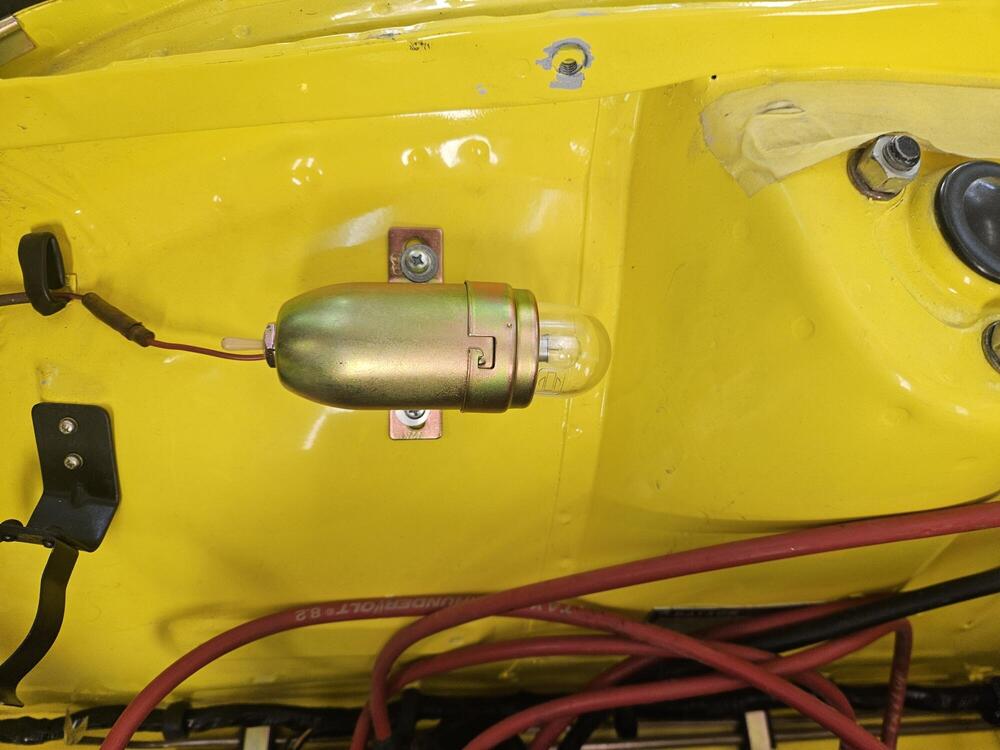

So I finally got back into the shop this weekend. A while back I was working on reworking some marker lights. Jim Arnett watched me struggle along with that for a while before he said "I have a nice set of running lights all redone if you're interested?" So yes, I'm interested! Jim does nice work and I got them in a week or so ago. I put the rears on yesterday and a engine room light that also came from him. I also got a new shift boot and rubber boot for the end of the transmission I also figured out how to get the maxima calipers apart There is a clip way down inside you need to get out I bought these snap right pliers. They work really good Needs some clean up Rebuild kits come in on Monday

-

Restoration of BringaTrailer 240z - HLS30-35883

That looks great!

-

Help ID brake calipers

What are doing about the bleed screw?

-

Updating cams

New cam, I would expect new or reconditioned rocker arms. Wipe pattern will have to be checked and that might require new lash pads...

-

Restoration of BringaTrailer 240z - HLS30-35883

I have the same alligatoring. I hadn't decided if I was going to try to fix it. This seems like a good solution

-

Still struggling with car at idle after 8 years

If it were mine I would swap out the entire ignition system. Coil and distributor with no pertronix

-

Still struggling with car at idle after 8 years

You still running the pertronix???

- L20b Cody's Goon

-

Help ID brake calipers

I think the spacer goes between the hub and the rotor. So it would shift the rotor inboard

-

L20b Cody's Goon

So more exhaust work last weekend I can't load all the images I want to. I get an unknown server error -200 @Mike Here are the one's that did load Old next to new We couldn't get the exhaust back under the car once it was tacked up. So we cut it here and will add another Vband. It pretty much all tacked up up. Once we verify that, we will ship off the header for jet coating. The cross section on the new exhaust is 315% bigger then the stock exhaust (1.25" vs 2.5"). It'll probably be rowdy but Cody will like that

-

Restoration of BringaTrailer 240z - HLS30-35883

Man I hope mines right. I don't want to have to pull it back out!

-

Door latch stuck

Steve's website very often shows out of stock but he will make them on order. All of his parts are hand made here in the US

-

How much is too much - metal shavings in oil pan?

Bearings are usually non ferrous. I agree, debris in the pan at 800 miles isn't a good sign. I would change the oil on a shorter interval for the next couple of changes and cut the oil filter open too to see if the engine continues to make debris. Maybe it was just an anomily

-

Z's on BAT and other places collection

Did you all read all the comments? BaT threatened the seller with a site ban if they don't close the deal. BaT evidently has the right to add the difference if a car gets close to reserve...

-

1973 Rebuild

You could shorten the port by an 1/8"

-

Rhythmic thunking slowing to a stop from right rear

I'm not a huge fan of clamping brake lines but it shouldn't hurt them

-

Rhythmic thunking slowing to a stop from right rear

I like the idea of swapping axle shafts side to side.

-

Rhythmic thunking slowing to a stop from right rear

I like the idea of swapping axle shafts side to side.

-

Restoration of BringaTrailer 240z - HLS30-35883

Interested in what they say

-

Window tint

I would tint after install. A good tint shop aught to be able to trim right at the gasket accurately enough. Also if the tint needs changing you can remove it all and replace. And also for the reasons you have expressed

Subscriber

Subscriber