Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

The thin metal plate is under the hinge. Just an optical illusion. I had considered removing the hatch and rubber boots. Cleaning them up. Reseal them but install the hatch to make sure they seat low enough. I really think mine had sealant on them when I removed the old ones. Sort of the wrong direction but I think it's gonna have to be done.

-

1971 HLS30-14938 "Lily" build

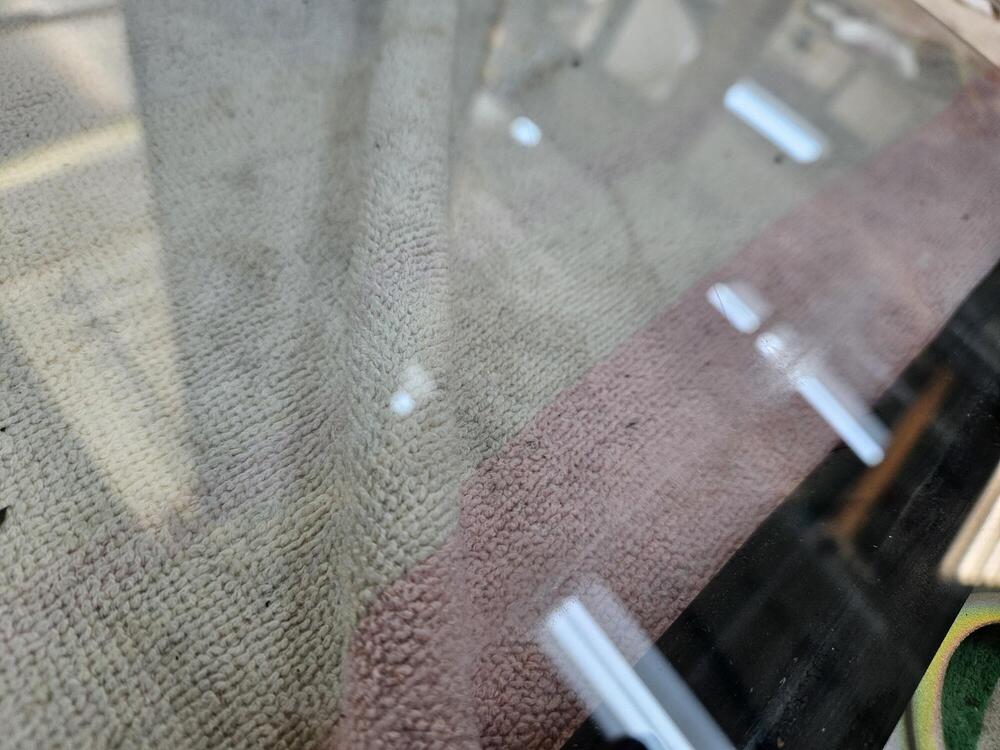

Here are the quarter windows This one looks pretty good. This is the main flaw in the other one Hopefully this corner will settle in eventually. The good news is I can't see it from the drivers seat! I polished the other door glass yesterday. The is Cerium Oxide. You have to make a slurry. It cleans it up pretty good but donesn't really remove big flaws. You can see the line of scratching right at the belt weatherstrip. I filled the differential. The hand pump blew an end off at one point and blew that stinky stuff all over me!! I got the hatch strut on yesterday too. It looks really nice @jfa.series1! I have a problem with the hatch hinges though. When I lower the hatch the hinge hits the ruber hinge cups. I am thinking there is too much sealant under them. I can force the hatch down the last few inches but you can tell the hinges don't move nay more. Can some body vouch for the hinges being supposed to clear all the way closed. When I lower the hinges down I can't get the hatch to flush up with the roof because of this interference.

- 1970 HLS30-06521 Re-Restoration

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Congrats on the BaT auction! I hope you're pleased with that number. It went up a lot at the end. It seemed like a good price to me...

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

More details on the car please

-

Transmission Tail Shaft Break-out Repair ideas

Copper would be my choice for backing

-

Recommended Bodyshops for rust repair? (east coast)

Diseased would probably be the best source. He's in VA. So not too far away. He know Eiji well.

-

Restoration of BringaTrailer 240z - HLS30-35883

That's what I did. There is a 1" wide path where the window roller use to be on the door. I assume it broke off and then the remnants scratched the glass up. The CerOx is just not aggressive enough to get that scratching out. It will take something more aggressive.

-

Transmission Tail Shaft Break-out Repair ideas

I think that's a decent plan, if it works out. I have never done any aluminum welding. Cody has taken a stab at some Aluminum TIG work and it can be unpredictable.

-

Restoration of BringaTrailer 240z - HLS30-35883

I understand. I was working on putting the metal brackets back onto the door glass yesterday. The passenger glass has some scratching and I used some Cerium Oxide on it, but it's not going to be enough. I will have to get more medieval to get the glass polished properly. Was just curious if you had gotten it figured out.

-

Restoration of BringaTrailer 240z - HLS30-35883

Garrett, Did you ever get your glass polishing figured out?

-

1971 HLS30-14938 "Lily" build

Those are all Precision seals. They're not perfect around the glass. Maybe they'll get better with time

-

Help identifying ROTA RB finish

I agree with the vendor. I think the gunmetal will look more black. The Hyperblack have so much metal flake in them that they look silver grey from many angles. They only look black under certain lighting conditions

-

1971 HLS30-14938 "Lily" build

Went to the shop last night and worked on qtr windows some Old Old glass seal was toast New upper qtr seal They are ready for the car now

-

Help identifying ROTA RB finish

I think those are Hyper black. I just ordered a set of those

-

Restoration of BringaTrailer 240z - HLS30-35883

SteveJ has a tutorial somewhere on a bench he built for just this type or under dash work

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

I assume there is no wideband available

-

Can't find fitting to repair paint gun - help?

I might have a donor gun?

-

Door Internals Window Mechanisms Regulators, Etc

Get him!!!

-

Dave W 1971/240Z rebuild

Have you done the hatch inner weatherstrip yet? I need my tutorial 😁

-

Door Internals Window Mechanisms Regulators, Etc

I have also never left the glass in with the regulator out. I usually take the glass out first. Then the window frame

-

280z Steering Wheel Vibration

What centers the wheel on a Datsun? The hub bore or the lug nuts? I had always thought the lug nuts centered the wheel. If thats the case the hub or wheel could be relieved so it sits flush. If thats not the case then it gets tougher and the machining needs to be more precise

-

Still struggling with car at idle after 8 years

I would think permanent use is not a good idea

-

Still struggling with car at idle after 8 years

Thats worth a try

-

Still struggling with car at idle after 8 years

Valve seals on #4 have been replaced

Subscriber

Subscriber