Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

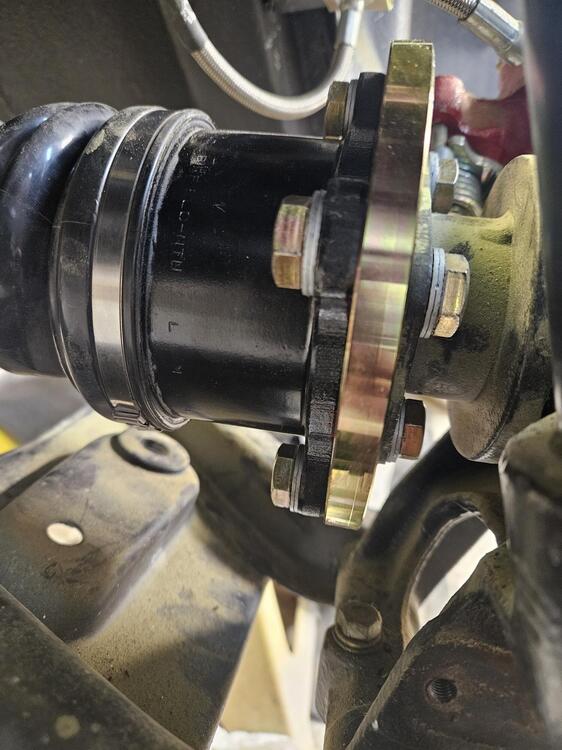

I worked on the second quarter window some today. This is the remnants of one of the corner seals. The old glass seal was crispy I also got the proper bolts into the axle adapters The stub axle side is 17mm 10.9's and the differential side are 22mm 10.9s. You can see in this picture the difference in length I have the quarter windows most of the way done today.

-

1971 HLS30-14938 "Lily" build

Yes! So I guess the second picture is probably the more correct where it laps up onto the window frame?

-

1971 HLS30-14938 "Lily" build

I have a question about the lower quarter windows seals. How do they go on? I can't find any images of them installed.

-

Reference for Door latch mechanism rubber parts. 70-76

It would be interesting to see some posts or a thread about restoring the latch mechanism including the rubber bits and how they install Also that link doesn't take me Mark's relevant post but to the first page of his build thread Nevermind, depending on where you select changes where you end up

-

1971 HLS30-14938 "Lily" build

So yesterday I was home early and Shelley ran me off to the shop to make some progress. So I worked on the drivers axle some more... Here is the end of the axle. Very tapered and no burrs. So I unbolted the top of the strut and layed it down out of the way. I put the adapter plate on and beat on it some to dome the grease cap out some to give me a little more room I put a some grease on the snap ring in the differential and tried to work it around some. The I took the 3# dead blow hammer and I got it to seat. The bolts that go in from the stub axle side just barely fit I got it all in and aligned. I does sort of bind at full droop, but if you lift the hub a couple of inches it has some play in it. I am not sure if the tulip on the inboard end is reversible. At this point I'm moving on. I will double check once the car is down on it's wheels and revisit it if it becomes a problem.

-

Watanabe Wheels and Brake Kit Options?

Have you tried asking them directly?

-

Black out areas

-

Does an LSD need better cooling?

Here is a dwg Datsun LSD brace.dwg

-

Does an LSD need better cooling?

Post #415, pg 35; post #500, pg 42; #541, pg 46, #544, #569

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Well done

-

Does an LSD need better cooling?

I will look for it

-

Does an LSD need better cooling?

There is an aluminum after market part that is available to replace that cross member. I tried to find it real quick but I didn't see it. Or you could modify the rear cross member the way I did in my build thread

-

Restoration of BringaTrailer 240z - HLS30-35883

All of the reproduction bumpers are stainless steel I believe. Group Harrington(?) from the UK might be the exception to that. I have a set of repop stainless bumpers. They're ok but seem to be soft and scratch easily. Hard chrome is much more scratch resistant. On a car built to this level, I would want chrome.

-

1971 HLS30-14938 "Lily" build

The end of the shaft is very conical. I'm thinking there's some other issue

-

1971 HLS30-14938 "Lily" build

I did try that. I used a 2" Rolok brilo pad and smoothed the end a little bit and made sure there were no lips. I used grease too. Still no luck... I'm not sure I can get the clip out of the diff. It's pretty far in there. Maybe 4-5"s. I had thought about getting it out and seeing if the axle would go in then, but again, not sure I can get it out.

-

1971 HLS30-14938 "Lily" build

I also worked on the CV axles and adapters. What a pain in the ... So both axles were a little too long at full droop. So I had to open the ends up and reverse the Tulip cage to make them a little shorter. I also ground off the end of the shaft to make them a little shorter maybe 3-4mm. You need all you can get. They also interfered with the ST rear sway bar. I'm wondering if the bar is supposed to go over the half shafts?? So I took the bar off for now I also worked on the parking brake some to see if I can get it working. It will clamp, sort of, but it doesn't want to back off. But the calipers are dry inside. Cody thinks I aught to bleed the brakes before I get too worried about that yet. I got the passenger side CV axle in after about 4 or 5 tries and making it as short as possible. I shorted the drivers side CV axle but I can't get it to snap into the differential. Even pushing with a pry bar. It aught not be that difficult to get in. The passenger side went in without too much fuss. You have to pry it out but it snaps in pretty easy. I was hoping @grannyknot or @Zed Head or some other member who spends time at HybridZ could give me some direction on how to deal with the axle I can't get to snap in. I've looked in the diff and the snap ring doesn't look like a problem. So I have no idea, but it's really frustrating!!

-

1971 HLS30-14938 "Lily" build

So I made a little progress a couple of weeks ago and a little more today So two weeks ago I terminated the other end of the parking brake cable. I weld the first end but decided I would try something different on this end. So I epoxied the pin and added an aluminum crimp behind it I also got in an order from Eastern Beaver and finally got the fuel sender ends redone. I softened these a few years ago with wintergreen oil but it didn't last. I got new boots from 240zrubberparts and new ends from Eastern beaver. Cut the old off and re crimped new ends

-

Z's on BAT and other places collection

I was really interested when it was cheaper, even though I don't really have funds to divert that way but it got out of reach about halfway through.

-

Z's on BAT and other places collection

Sold for $82,500. I think that's a solid price. It would have probably brought a little more a few years ago

-

Restoration of BringaTrailer 240z - HLS30-35883

When they show chrome, they build up lots of copper and then block sand it back down to make it flat like filler work. It is time consuming. You figure a couple of days for each bumper. So it adds up quick

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Yes, I believe you understand. I would try to do three pieces about 6' long. You actually don't have to pick the whole side up at once if you can't. The building will "flex" some if you pick it up in one area and not another. You can get it jacked up and then cut temporary studs to length and then you can move the jacks around. When you want to set it down you can drive each stud out a little at time so they all come down evenly or you can use the jack again to lower them. A 2x6 as a top plate works better than a 2x4. It's wider and stiffer...

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

A bad back is no fun! If the rafters and celing joist are tied to the wall plate well enough, you can setup a temporary wall inside the existing wall about 12-16". Use bottle jacks and temp posts to jack up the ceiling structure. It should take the wall with it. Be sure you have all the studs free from the plate. You dont need a lot of movement to have enough gap. You may have to replace the sill on shorter sections to get it in there.

- I like them bouncy...but not my speedo needle

-

Windshield Sprayer Nozzle

That was a fabulous car!

-

Windshield Sprayer Nozzle

It would be nice to see a reproduction but I bet they would be surprisingly expensive. They are more complicated than they look

Subscriber

Subscriber