Everything posted by Patcon

-

Restoration of BringaTrailer 240z - HLS30-35883

I will work getting them posted. I probably didn't do them yet

-

71' Fuel Filter Level

Having a spare set of carbs helps eliminate a lot! Fuel: weak or sporadic pump, bad tank or lines, too rich? Ignition: bad coil, bad cap, bad dizzy More vacuum leaks

-

Dave W 1971/240Z rebuild

What do you do about overspray at the door edges to prevent blowing in on the door jamb?

-

Quaife LSD Installation in R180 - With Questions About Installation Also

It looks like this link might be behind a paywall...

-

Quaife LSD Installation in R180 - With Questions About Installation Also

I am always looking for something to read when the forum is slow!

-

Dave W 1971/240Z rebuild

Will you leave the interior in primer or color it?

-

Dave W 1971/240Z rebuild

You're flying! Great progress!!

-

Quaife LSD Installation in R180 - With Questions About Installation Also

You could probably also link to the UK site in your thread

-

Quaife LSD Installation in R180 - With Questions About Installation Also

@AK260 Be sure and post up your experiences. Either in this thread or a new one. This is a topic that could use fleshing out as so few people have attempted this rebuild

-

Need R200 Differential Advice

I understand. The three shops I recommended have very good reputations

-

Restoration of BringaTrailer 240z - HLS30-35883

I believe the resource section has templates for them except maybe the floor mats. Unless I forgot to post my tunnel templates?

-

12v Battery Recommendation

The wires aren't very expensive...

-

12v Battery Recommendation

Where is the positive terminal on the old battery? I prefer to get one that has the positive terminal away from the fender.

-

Restoration of BringaTrailer 240z - HLS30-35883

Where did you source that?

-

Need R200 Differential Advice

Well, you answered one of my questions. You still have the noise on a cool differential. I wouldn't get rid of any CLSD r200! If even for parts in the future. If it was me and I could afford it, I would find a rebuilder to go through it. Especially after reading inline6's thread on what he's gone through trying to do his. Call Rebello, zcargarage or Datsun spirit for a price or a recommended shop to do the work.

- I like them bouncy...but not my speedo needle

-

Tuning With An Air/Fuel Gauge

@chaseincats Being in Texas I wouldn't think smog or inspections would be an issue?

-

1971 HLS30-14938 "Lily" build

That might be nice!

-

1971 HLS30-14938 "Lily" build

Testing headlamp bulbs in the shop the other day. Another use for the jump box. I have an LED kit that SteveJ recommended but I figured I would start this way and then add the LED's in later

-

L20b Cody's Goon

Cody worked on the parking brake some more. We figured "while we were at it..." So he took it all apart. He bead blasted the black parts. We didn't paint them yet because it's been so cold. He did buff out the brake handle Finished Didn't get the teeth totally perfect but I think it will be ok Used a little Boeshield to protect it

-

Tuning With An Air/Fuel Gauge

I believe it is Kilo pascals...

-

Quaife LSD Installation in R180 - With Questions About Installation Also

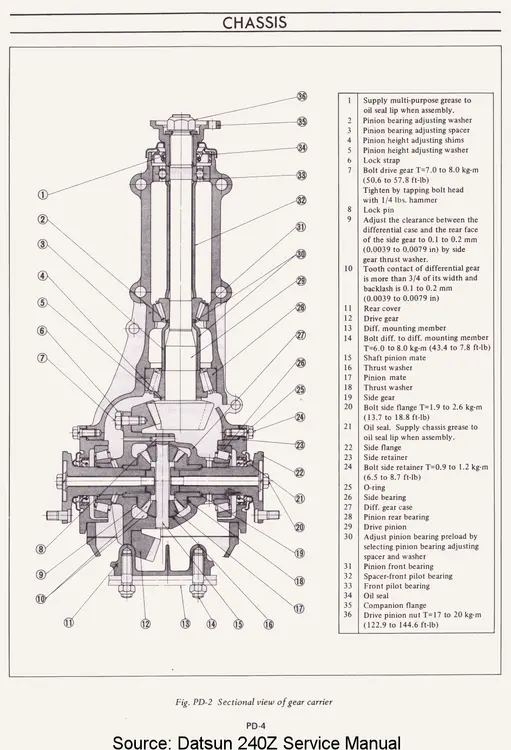

So the shims your are changing on the pinion are #4 on this diagram? The side shims are #9 & #18? If so adding shims is going to reduce lash because the pinion gear is conical and as it moves further back in the case lash is going to go down, but that's going to move the contact pattern on the ring. I'm not sure that I would hold to this instruction about overall thickness. You've got a new center section and new bearings. It's possible that a minor manufacturing tolerance has changed the overall thickness needed. I would be passionate about keeping the original contact patch in the same place though.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

So you checking sounds correct. Just make sure your indicator is set at the very outside and tangential to the ring. So, from the sound of post #70 you changed two things at once and you are currently focusing on the shims at the front of the case? I had a thought, so I did some research to see if I was on the right track. I have never done a differential, so I wasn't confident in my thought process. I thought you need to set the depth of the pinion in the case and then adjust for backlash. I forgot about preload. That would be second. So it's my understanding that the shims at the front will mainly change patterning. While this will affect backlash, that's not the main purpose. The side shims are used to adjust backlash. Move the ring closer for less backlash further away for more. Here are some things I found. Take all of these with a grain of salt because alot of these are solid axles but most of the info aught to transpose. https://www.randysworldwide.com/blogs/gear-backlash https://www.yukongear.com/blogs/12-tech-tips-for-differential-assembly-setup_1 One of the main things I took away from this thread, was if you move the wear pattern, it can "sing". https://www.garagejournal.com/forum/threads/adjusting-an-old-ring-and-pinion.447201/ So I would try to keep the wear pattern as close to the original as possible. I believe as the lash goes down the heel/toe drive/coast patches will move towards the center of the tooth. Did that make sense?

-

Quaife LSD Installation in R180 - With Questions About Installation Also

@inline6 So a question? Quickly, what is your method for checking lash?

-

Where oh Where has Zedyone been?

Artemis mission, super cool!!! We would love a lake house but Im not sure we'd make time to enjoy it. Just too many other things taking time

Subscriber

Subscriber