Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

I try to tape off all those decals before I bead blast them and paint them. That would be great if you can use these pictures later!

- Heater valve

- L20b Cody's Goon

- Heater valve

- Heater valve

- L20b Cody's Goon

-

1971 HLS30-14938 "Lily" build

We have one shop locally that would probably do it. I thought I might take a shot at it myself. If not I'll have them do it. So I have a spare for me or someone else

-

1971 HLS30-14938 "Lily" build

I was working on the heater box some today. Tested the heater core that came in Lily, it's cracked! 😞 They are evidently, not readily available. "Brassworks" will custom make you one for $425! So I dug around in the shop and found another one. It tested good. They both appear to be factory units.

- L20b Cody's Goon

- L20b Cody's Goon

-

Heater valve

So I am messing around with heater boxes right now and I was pressure testing two heater valves I had. I cobbled together some hoses to attach my coolant tester to. One valve did ok, although it leaks slightly around the push rod when it's being actuated. The other leaks badly as the junction of the brass body to the steel bracketry. So in the best Captain Obvious manner, I decided to take it apart! Folded the ears back and removed the bracketry The internals just pull out after that There is a square O ring seal between the hard plastic end and an inner washer. I think if it were replaced the valve would seal up. I've started looking for suitable O rings without having to buy a 100qty. Bead blasted the valve body just for fun

-

Air chucks

- Air chucks

- Total internal reupholstery

I think its heat welded. It may make it difficult to maintain a crisp edge when removing the chrome trim. It is also easy to make the chrome peel- Servicing Cooling System Questions

Only because you haven't assembled your at home hardening line...yet 😉- Taillight Gasket Exhaust Leak?

Maybe try without the tape first. Otherwise you wont know if the seal and peel actually worked- Total internal reupholstery

I believe the chrome strip molded to the vinyl on the panel. I don't believe it will come loose with the rivets Maybe Cantech can verify.- Air chucks

I have bought Milton HiFlo hose air chucks for years. I've been really disappointed in them in recent years. Them seem to start leaking pretty quickly as of late. What is everybody else using? Anyone else's experience?- 1971 HLS30-14938 "Lily" build

@Namerow What is the best way to use those templates? I would print them but that seems like it would use a lot of ink. Is there a better way to do it?- 1971 HLS30-14938 "Lily" build

Worked on the heater box some more today. Blasted the cases. Primed and painted. Blasted the hardware and strung it. Ready for plating. Need to test the heater core somehow- L20b Cody's Goon

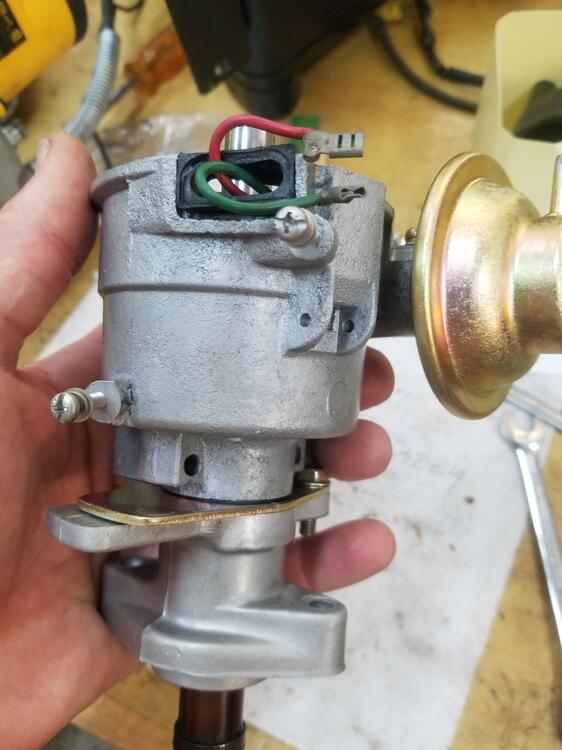

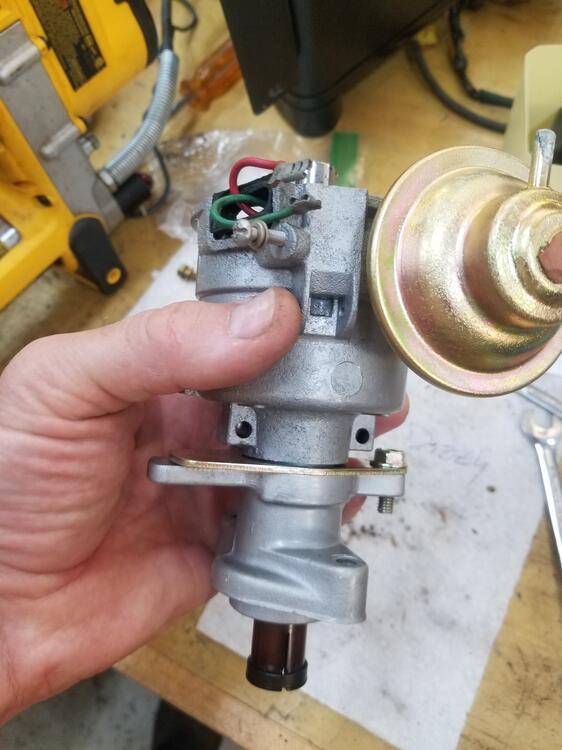

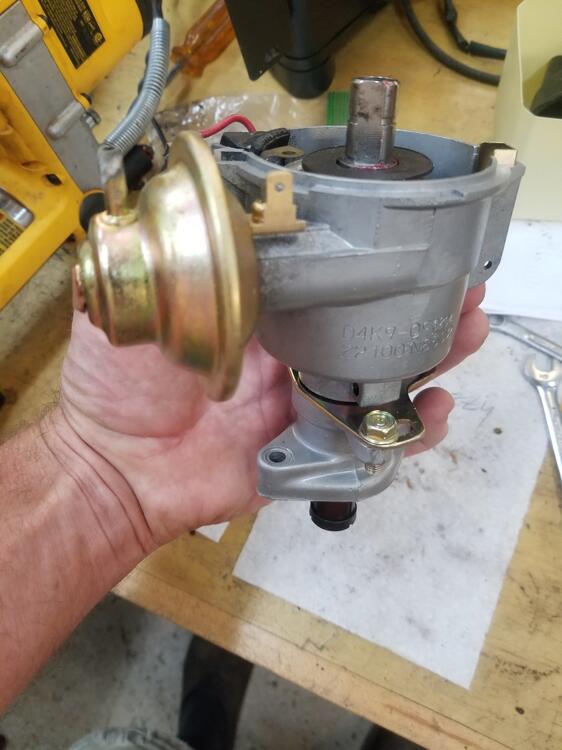

Worked on the dizzy some more. Got the advance shaft disassembled and polished the shafts. It would appear the mechanical advance is going to be 13d? Disassembled this part too I took lots of pictures! There are several little details that would be easy to miss on reassembly Might work on this part some more tomorrow, we'll see...- Caswell Plating

I plated the vacuum advance the other weekend I wired it and then put the hose on it to keep the liquid out. I plugged the advance port It turned out pretty nice for as crusty as it was. What was interesting was when it was in the tank one side would get really shiny but the other got dark. Rotate the piece and the discolorations would move. So at the very end I just wired the negative directly to the wire coming off the part and held it in the tank by hand. I rotated the part slowly and all the plate brightened up. It was really cool to watch. So this would tend to support barrel plating as giving the best finish results...- Replacing All Large Opening Seals & Hatch Small Seals

How do you do this heat and oil black thing?- A/C trinary switch

- Engine rebuild smoking

That's too funny! Well at least he's confidant in his work! That's what you want. - Air chucks

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber