Everything posted by Stanley

-

Heater Hoses Plugged

My take-away from the threads mentioned is that recycling hot water from the head back to the water inlet raises engine temperature. The stock system recycles water through the heater as stated and also through the manifold heater tube. This is supposed to be beneficial while the engine is warming up, before the thermostat opens . The manifold heater tube has a hot-closed thermostat. I tried several things: leaking heater valve (coolant on floor), heater bypassed (looped), looped with restrictor, and currently everything plugged. Seems to run cooler now. I tried the Dorman rubber caps but they were shot after 6 months. Now using tapered rubber plugs (about 35 cents each at Ace hardware) in the stock tee fitting on the side on the engine, with silicone caps (M-C) clamped over them for safety. A BSPT plug is available (M-C) for the water outlet on the head. I've got one, but I hooked a short piece of semi-clear high pressure silicone hose (M-C) to it as an experiment; now I can see the coolant level without removing the radiator cap.

-

Need a list of necessary engine hoses

The short hose from the thermostat to the intake manifold heater tube takes a tight bend, so it might be better to buy the special hose (or get a 1/4" BSPT plug for the thermostat). The PCV hose is bigger on one end, so it's better to buy the special hose, it's not expensive. You'll have to hook up new heater hoses or plug the heater outlet at the rear of the head and plug the water hose outlets on the right side of the engine. I use Goodyear Hi-miler heater hose (rate for 360 F. IIRC.) for the side hose because it's so close to the engine it can crack at the clamps from the heat, at least mine did. Cheaper than silicone. The heater might leak, since the hoses aren't hooked up (or I need better glasses). Nissan still sells nice radiator hoses, that say "Nissan". I changed all my fuel hoses to USCG marine grade, fire-resistant and lined to resist ethanol. Using F.I. type clamps since they're a little thicker.

-

What happened to the Z's restored in the 90's? - news article

What Happened To All The Datsun 240Zs Nissan Restored In The 1990s?

-

Frustrating performance.

Helps to keep a notebook in the car, write down float setting, mix settings, idle speed, timing at idle and 3000 rpm, dwell, plug condition etc. with the date. Also vacuum, fuel pressure, and compression if you have the gauges, alternator voltage and anything else that might help. If you have a stopwatch, you can write down zero to sixty, sixty to ninety, etc. after each adjustment. Just have to remember where I put the notebook.

-

Bar's stop leak....

JB Weld can work if the leak is accessible. Got a leak (Chevy truck) on a July trip to a remote desert area near Tucson about 12 years ago. Drained and saved the coolant, put some JB Weld on the leak. Surface prep is important. It survived the trip back in 115 F weather and is still OK. Found the Z's intake manifold heater tube completely plugged with the PO's stop leak. Had overheating problems until I installed a new radiator, it was probably somewhat plugged. Before putting in a new radiator, flushed the engine 3 times.

-

Windows XP, Windows 7, Windows 8

My win 7 laptop went blue-screen Saturday after restarting for win update. Took it back to Best Buy, Geek Squad, they got me for $200, called me yesterday and said they can't fix it, maybe the motherboard. $100 to back up the documents. so I called HP, they'll fix it for 350 incl. shipping and free docs backup. OK. Anyway, I checked out laptops at the store, they all had win 8.1. Tried them out, seems like a hassle if you need to have access bunch of recent docs, like putting a set of plans together. Maybe it's OK but that's my first impression. Glad I opted to fix my win 7 laptop instead of buying a new one. No job this week fortunately but hate not flying my damn planes. Wanted to get my wings wet under Victoria Falls, miss the Grand Canyon. Oh, yeah, don't be like me, please back up your files, Z stuff etc. 500 gigs storage for $70, so no excuse.

-

Replacing Twice Pipes exhaust! How to go back to stock without buying unnecesary part

I'd just go to a local independent muffler shop, have them install a pipe and muffler. Just explain you want it quiet, and as much ground clearance as possible. Stock pipe reduces performance. Installing 2 1/4" pipe and turbo muffler (with an adapter welded to the stock Y pipe) took about 1.2 seconds off my 0 to 60 mph time with no other modifications. And it's not so loud I'd get a ticket.

-

Occasional top-end miss: Fuel or ignition?

The week before the dyno I Checked the floats, front one low so I adjusted it up to stock height, rear was OK. Have a pair of sightglasses to check fuel ht. (at no-load). Should have hooked them up at the dyno. Hindsight 20-20. However, post #23 might be correct, so I'll try raising both bowls 2mm above stock ASAP. Also the needles and nozzles are new (six months old). The old nozzles were shot. MSA didn't have 72's so I got 71 nozzles with the N-27's, as they recommended. Wonder if there could be an issue with that. Also wonder if fuel pressure could be an issue, even though it's OK per FSM. Maybe it needs a little more to keep up? According to the Ztherapy video (in the British SU section) fuel pressure affects A/F ratio. There was a post about someone needing more than stock fuel pressure, but I think they were racing, maybe bigger engine.

-

Occasional top-end miss: Fuel or ignition?

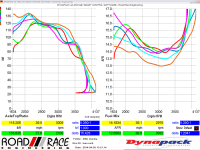

This shows the effect of lowering the mix nuts after each run. First run red, then green, dark blue, violet, light blue, and last brown. About 5 1/2 turns down on the last run, still "running on empty". Torque falling off accordingly. Floats approx. stock ht., F. press. steady, about 3.7 to 3.9 psi (don't remember exactly). Raised the mix nuts up some before I drove back, and another half-turn today - using too much gas.

-

Any floats yet?

Oh. Yeah. Regarding the StayUp floats, That one looks like it, but might be wrong size float or attachment. But from their FAQ's, looks like if it doesn't work, they could probably make them if somebody sent them one to copy. Maybe there's a CZCC member near their location.

-

Occasional top-end miss: Fuel or ignition?

They're going to email me the results tonight or Monday. They couldn't get it into the best power range, they shut it down when A/F went up too much, glad they did. I saw it on the computer, though. Didn't take much notice of the torque/HP since I was focused on the A/F ratio. It was taking a sharp turn up at top end. Sounded like it was running out of gas. I guess there's a big difference in fuel requirement between load and no load conditions. I'll try the floats again, but starting to wonder if there's something else happening. I retarded the timing slightly, since they heard a ping and didn't want to run it until I did. A little less peppy but I feel better about it, especially considering the lean-out issue.

-

Occasional top-end miss: Fuel or ignition?

Proof today at the dyno at MSA. Although the fuel level in the bowls is stock or very close, it's still running out of gas over 4500 rpm. Seemed worse on the dyno than driving. Did several runs and adjusted it richer each time, which improved it, but even at 5 turns down it was still leaning out at top end. Fuel pressure should by OK, 3.6 to 3.9 psi. Fuel flow seems good too. Don't know what' up with it, sure glad I had it dyno'd, though.

-

SU Float adjustment: float hitting side of bowl?

Got it adjusted today, no problem, gremlins had a day off. Talked to the mechanic, he said there are some things, other than setting the tang to low, that will cause overflowing after a float adjustment: float hitting side of the bowl, valve sticking open or not sealing, and float sliding off the pin.

-

Occasional top-end miss: Fuel or ignition?

Looks like it was fuel. I thought the floats were set correct height but when I checked them the front one was down about 5mm. Did many adjustments, finally got to about stock. Might try a mm higher. The rear float was still where I set it, but might also try raising that one a mm or so. Took a drive, tried WOT a few time, seems OK. I'll keep checking but looks like it's fixed. I altered the mix by raising the fuel, time to reset for summer it anyway.

-

Roll Call for ZCON 2014 Who is going/coming to San Diego?

I plan to be there, just as a spectator for the car show.

-

SU Float adjustment: float hitting side of bowl?

Interesting link. And I ordered a carb tune-up kit just to get the valve, although the valve seems to work OK. The floats not hitting the bowl, at least not now. Did a little experiment to see how far the float was moving. Ran some dental floss through the vent, around the tang and back up through the vent, so I could pull the float up with the lid on. No gas in the bowl. Got the red straw from a can of carb cleaner and put it in the vent so it sat on the float. Marked the straw with the float all the way down, then pulled the float up with the floss until I felt resistance (the spring in the valve) and marked it there. Then pulled it all the way up and marked it again. Checked with micrometer. About 8mm from bottom mark to middle mark, and 12mm bottom mark to top mark. So looks like about 6 to 8mm of possible adjustment, at least on the front carb (3 screws with longer ears on front carb) with the washers I have under the valve. FWIW. Took a drive, think one or both bowls still going dry (or dry enough to lean out the mix) at top end when I keep it floored. Never a problem if I ease it up to 5000 rpm. All my adjustments didn't help any. Had to put it back together to get groceries, though. Try again tomorrow.

-

Looking for a set of N27 Needles

I bought a set of N-27's about ten minutes ago from MSA. I think ZTherapy sells them too. According to MSA online catalog they go with the '71 nozzles, can't verify if that's correct though.

-

SU Float adjustment: float hitting side of bowl?

I noticed that once the float is adjusted to near the factory setting, which makes the bowl about half full, any further adjustment will make it overflow. Make a very small change of the tang on the float, and there's a small change in fuel level. Make another small change there's a large change in fuel level and the bowl overflows. Using a sight glass to check fuel level. Maybe the float is hitting the side of the bowl so it can't go higher and close the valve. I straightened up the float so it wouldn't do that, but it hasn't helped. I though of sanding the float, but that might make it soak up gas. I thought of a way to see if it's hitting, I'll try it today. But I wonder if others have noticed this or have some insight.

-

T-Bucket in Gardena

-

MSD 6A with points?

From my reading and re-reading, that could still be wrong, 8920 tach adapter is for magnetic pickup distributors, 8910 adapter is for voltage triggered tach (some early or later Z's?). For the current driven tach like my early 73 it says use Chrysler ballast that "May" work. Don't want to pay $180 until I know if it can work or not. Datsun gets me to work and back so I can't sit around pretending and hoping I know what I'm doing if I don't. Sounds like that electronic conversion would work though. $6 parts sounds OK. Might need some circuit board experience, though.

-

Any floats yet?

Remember a discussion a year or two ago about floats for the SU's. Who might manufacture them etc. Any good news? Think my front float is shot. It's not where I set it, checked it then (and took photos) and now with a sightglass. It's down about 5 mm. Either the float's soaking up gas or possibly the tang is weak; don't know what else it could be. The other float is exactly where I set it over a year ago. Those things are about as high-tech as a marshmellow, so you'd think someone could manufacture them.

-

MSD 6A with points?

Least amount of fuss, exactly. Also least amount of money. I get the 6A box for $180, free shipping, which I can do, anything else not at this time. Recently invested in three sets of genuine Nissan points, and my distributor is almost new. Have a small-port, higher compression (than stock) head that puts my shift points for quickest runs under 5300 rpm. Even if I put a cam and headers I doubt if I'll be shifting over 6000 so I think points will be OK. Not a race car anyway, just like how it goes when it winds up. Saw a similar question about MSD/points, posted by Conedodger, wonder if that worked out.

-

MSD 6A with points?

Anyone using MSD 6A or 6AL with points? Searched all the posts, lots of threads (problems) about hooking it up to 280zx distributor, Unilites, Pertronics, but found nothing useful about using it with points. So either it's impossible, or seems too difficult, or it's so easy nobody bothered to post a question. My '73 240 has stock Euro distributor and stock wiring including a regulator. The tach wires to + terminal on coil (distributor wire is only thing on - side), so if I understand, it's a current triggered tach (9/72 build). I counted 6 wires on the tach so maybe it's a 4-wire (!) if that matters which I doubt. Anyway according to the instructions, it needs a Chrysler ballast (instructions:"The additional resistance may correct tachometer function"). Don't like that "may". There's a diagram of that that's confusing to me (which wires go where) on pages 2 & 3.MSD 6A misc.pdf Here's a PDF, shot of my tach and stuff compiled from the instructions that might be relevant. Photos might help, especially how that ballast is hooked up.

-

MSD ignition - easy?

Guess whether it's easy or not depends on if you've successfully done it on a stock 240Z before. Just spent an hour downloading and reading the instructions. Seems like a diode might be required if there's a separate voltage regulator (there is). And the possible need for a "dual ballast resistor". Looks like the Tach adapter I planned to get won't work. So not easy. Some photos would help figure out which wire goes where. Remember reading somewhere that electrical stuff runs on smoke. If the smoke leaks out there's a problem. Time for a beer.

-

Weld shut or bondo very small holes in body?

I don't have the skill to weld it without making it worse, so I'd use JB Weld. Maybe get a little stainless steel screen for faucets at the hardware store, or cut a little piece of galvanized screen and stick it on the back with some JB Weld. After it sets solid, fill it in from outside with more JB. A little bondo to finish it off since it sands easier, then some sanding primer.