Everything posted by Stanley

- SU carb-correct screw adjustment?

-

Coolant hose driver side

The tube that runs around the back is larger diameter than the tube that runs through the intake manifold. If you run a hose from the thermostat housing around to the heater Y-pipe you're going to be sending more coolant around at all times, bypassing the radiator, than the stock intake heating system would when it's thermostat is open. A way around this is put a restrictor in the line. Maybe jamming a socket inside the hose would work.

- SU carb-correct screw adjustment?

-

Intake / exhaust manifold spacers: necessary?

OK. The old ones are probably shot.

-

How much would you pay for this?

An OK Datsun can be reliable . Any car can be stuck on the side of the road. If you're thinking about those Datsuns you're not doing to be happy with the reliable Honda unless it's a modified '89 crx-si or vtec. The first car looks OK except the horrible rust above the windshield. If it was a Chevy you could buy a piece to weld in. The second one looks kind of stolen, by the looks of that number plate. spelling checker tags "Datsun".

-

Intake / exhaust manifold spacers: necessary?

Got some MSA headers since there was a problem with the stock manifold. The engine builder supplied some thick washers and the R&R shop owner thinks they're OK. I don't want to second guess those guys since they both know way more than me. Thought I'd ask though. If I need them I can order them today. Header is out getting some ceramic since the coated ones aren't available for awhile. The spacers are available at MSA: http://www.thezstore.com/page/TZS/PROD/classic19o/14-0373

-

Regulator / Gauge - Do I Need It?

Good idea to set up lines from float bowl vents to clear plastic catch cans to make sure there's no overflow. The catch cans should be located where fuel will go on the ground if they overflow instead of pooling somewhere (like stock air cleaner) or going on the exhaust pipe. I had the floats set slightly higher than stock for a while. Got about 1/2 ounce total overflow over a year.

-

Regulator / Gauge - Do I Need It?

I think 5 to 6 psi would be OK if you're running a return line.

-

New grill for 240z

Check out this grill I bought. Mine is bent bad. I was going for the JDM Fairlady style but like these better. Way better than a crappy old stock one for almost the same price IMO. Black Friday special too. https://skillard.com/products/datsun-240z-front-grill

-

Regulator / Gauge - Do I Need It?

Note that the pressure and flow in the FSM are tested by attaching gauge to the fuel pump outlet (return line out of the loop). So in a system with a return line, pressure and flow should be somewhat less. I'm not using a return line, getting 3.9 to 4.1 psi. Never had an overflow (with the floats at stock setting). It varies depending on whether the float bowl valves are open or closed. My gauge only goes from 0 to 5 psi so it's easy to see the variations. The gauge goes nuts when the car starts running out of gas.

-

Regulator / Gauge - Do I Need It?

FSM says use 10W-30, and don't use 30 wt. I'm currently using 30 weight but don't know enough to make a recommendation. Springs can also make a difference. I went to APT's red springs which got rid of a lean-out at about 4500 rpm. According to the "Just SU's" book stiffer springs improve performance at the expense of gas mileage, but very stiff springs reduce performance and increase mileage. It also states that SU's can equal side-draft Weber's if expertly tuned. Book learning can help but experience plus knowledge of theory plus experimentation is better. Lacking that I guess trial and error, with a stopwatch or dragstrip to check performance, is a good way to test modifications. I've got this badass math program that will do 3D (and 4D animated) graphs which I hope to use to illustrate some of this stuff. If I can just figure out how to use my badass math program, that is. Anybody up to speed on Maple 16? Page EF-3 of '72 FSM says (mechanical) fuel pump should deliver 1600 cc (3 3/8 quarts) in one minute or less. That's a lot. The '73 fuel system mod. bulletin says 3.4 to 4.2 psi and 3 pints/minute at 1000 rpm. 3 pints is way less the 3 quarts so dunno. 1600 cc = 1.69 US quart. Seems to apply to both mech. & electric pumps.

-

Regulator / Gauge - Do I Need It?

My gauge works great. Here's my secret: http://www.mcdanielcontrols.com/

-

Skyline Y-70 head on '73 240z engine in Torrance CA

Block is spoken for, NLA.

-

Skyline Y-70 head on '73 240z engine in Torrance CA

Block might be free. PM me if you want it. Otherwise junk yard. Nothing wrong a rebuild won't fix. Local Datsun shop wants the Y-70, trade for heater parts and repair but $400 still goes until weather gets colder.

-

Im at wits end please help

There's an FSM factory service manual for your year car on this site somewhere. It goes into SU tune procedure in detail with illustrations. If you don't have a printer you can put that chapter on a flashdrive and take it to a copy place to print it. It makes the tune way easier when the chapter is sitting on the fender.

-

240z alternator upgrade (instructions w/ pictures)

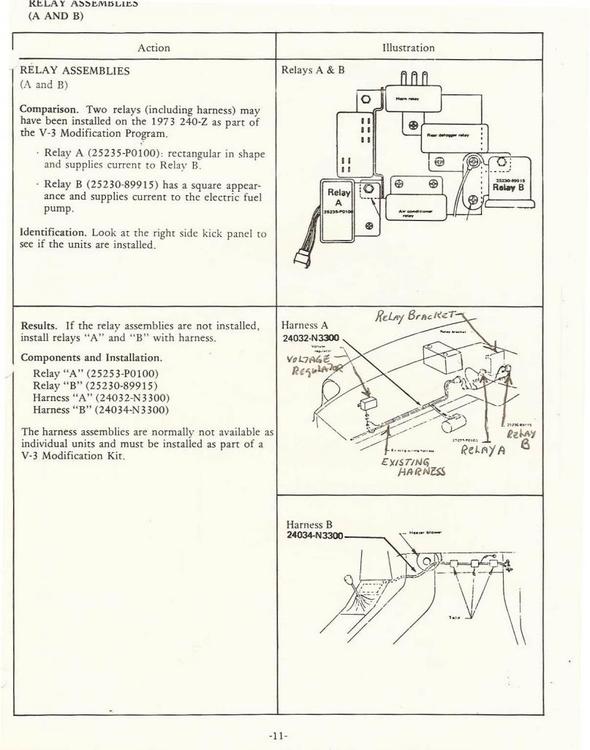

If the stock electric fuel pump on my '73 is removed do I still need to cut that elusive yellow wire ? I'll take a look in the car tomorrow but looking at the photos I posted, including the PDF's, I don't see any yellow wire coming out of harness B (the one at the relay nest). The instructions show how to hook up a electric pump but I'm not doing that now, maybe someday. Don't want to go nuts with the wire cutter, chopping every yellow wire I see. Before I removed it, the stock electric pump was disabled somehow with the wiring. It was hooked up but didn't run. When I removed it and checked it by touching leads to the battery, it ran.

-

240z alternator upgrade (instructions w/ pictures)

Whoops, looks like Dave just answered the question on auvelas thread.

-

240z alternator upgrade (instructions w/ pictures)

Also wondering about the stock ammeter with the upgrade. Seem to remember something about it not working but don't know if that is correct.

-

Regulator / Gauge - Do I Need It?

I find a gauge to be very helpful. It allows you to see that pressure is correct, and instantly rule out (or verify) fuel pressure as cause of engine trouble. Get a good gauge, though. You can run hoses from the float bowl vents to clear plastic catch cans (I use shiracha bottles) to make sure the bowls don't overflow. 5 to 6 psi might be enough to overpower the valves.

-

240z alternator upgrade (instructions w/ pictures)

I found a diagram of the '73 relays in a modification bulletin. The fuel pump relays are "A" lower left, and "B" lower right. I see a yellow wire coming out of the harness connector, don't know if that's the one you're supposed to cut.

-

Regulator / Gauge - Do I Need It?

FSM says mechanical fuel pump pressure should be 3.41 to 4.27 psi.

-

240z alternator upgrade (instructions w/ pictures)

Old thread but still valid. Here's four photos of the relays on my '73 that Dave asked for in 2015. I'm doing the alternator upgrade and have Dave's adapter from MSA. The alternator is already installed on my new motor which is still in it's crate. R&R Friday. I have no idea which one is the fuel pump relay or which wire to cut. relay photos 4.pdf

-

Jai's Status

If the problem is corrosion then you can blast it with WD-40, let it sit a few minutes and repeat. Then you can blast it a few times with carb cleaner to remove the WD-40, and maybe follow that with graphite when it's dry. It might not be corrosion, though. Sometimes something breaks inside the lock.

-

Skyline Y-70 head on '73 240z engine in Torrance CA

Engine and/or head will be available next week. Will consider trade. I need a nice '73 front bumper.

-

restore ugly valve cover (mistake to media blast?)

You're doing things right