Everything posted by Captain Obvious

-

Lowering Bottom Spring Perch

So I found front suspension parts on craigslist and went on a safari to grab them. Nice guy, reasonable prices, close enough to drive to for heavy stuff. I'm very happy with how the whole thing turned out. Front suspension loaded in the back of the Family Truckster: Got it home and stripped everything down. Here's the strut bodies and the Tokico's that came out: So that's where I am right now. Had to resort to the pipe wrench to get the gland nuts off, but other than that, everything went swimmingly.

-

Just Another Damned Z Car Project Thread

Why did you switch to Panasports? I've always liked the K1's. Something about them you didn't like, or just get tired of them?

-

260z round top conversion: a couple questions

I think the plan of leaving the manifolds and balance tube is a good one. If everything works out well you can always swap out the balance tube later if you get tired of looking at the EGR parts. As for the hard lines, some of them are water and some of them are exhaust. When/If you're going to switch over to a 70-72 balance tube, just cap all the water and exhaust ports off. If there's something specific you're concerned about, post a pic and we can talk about it. And it sounds like you're fine with the linkages. I think they only made two lengths (longer for the round tops and a shorter version for the flat tops), so if you got two different lengths from the guy you bought everything from, it sounds like you've got what you need there.

-

Price Check: 2" X 4" X 8' ?

Haha!! That was my exact thought as well! Great call!

-

Carbon Canister to Fuel Tank Hose

What? It wasn't obvious? Kidding aside, glad to help. Yeah, they took stuff out of the manuals over the years, and sometimes they added stuff. But it seems more removal of detail than added. (And I didn't look at the 78 manual (I stopped at 77), but you better believe I will now!!)) Hahaha!! Edit - It's not in the 78 manual. No surprise there.

-

260z round top conversion: a couple questions

Glad to help and good luck with the project. We haven't talked about balance tubes at all, but the bottom line is you can use any of them, including the one already on the car. The only "down side" to that one is the complexity and for that reason many people doing the round top conversion replace them with something simpler. And one tricky bit that you haven't hit yet will be the throttle linkage... The piece between the flat tops is shorter than the one used between the round tops. So for that reason, when you replace the flats with rounds, you'll find that center linkage piece to be a little bit too short. So keep your eyes open for some round top linkage pieces.

-

Carbon Canister to Fuel Tank Hose

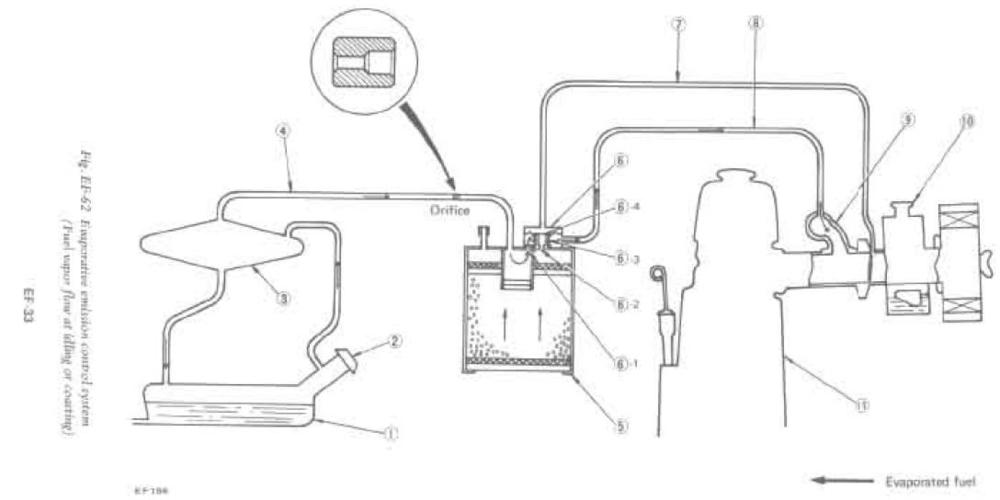

It's just a restrictor. As mentioned above, the check valve a different device. A little history... 1974 is the first year for the carbon canister system to capture and contain fuel tank vapors. Prior to that, they used the "flow guide valve" system in 73 and earlier. So, 74 was the first year for the CARB can, and on page EF-33 of the 74 manual there is a diagram of the evaporative emissions control system. Note that they call out the existence of that orifice. Also note that in subsequent years, they dropped that diagram from the FSMs. So my guess is that orifice was carried forward from 74 on, but they just didn't bother describing it in the manuals. I didn't study each and every manual from 75 to the end, but I took a quick look at a couple of them and didn't find any mention. Here's the diagram from the 74 manual that shows the restrictor orifice: :

-

260z round top conversion: a couple questions

On the flat top car models (73 and 74) there are actually three paths for coolant to flow through the intake track. All three of these paths start at the thermostat housing. First path comes out of the thermostat housing and passes through the intake manifolds. Second path comes out of the thermostat housing and passes under the front carb and then up into the balance tube (near the EGR valve). Third path comes out of the thermostat housing and passes through the carburetor bodies. All of those paths then gather back together again at the back corner of the block and from there they flow through the hard line around the back of the block. So I can't tell exactly which of those three paths is the one capped off, but you should be able to trace the lines knowing what you're looking for. If not, take some other pics from different angles and that should help with the ID.

-

260z round top conversion: a couple questions

Oh, and what's the next question you want to work on?

-

260z round top conversion: a couple questions

If you're planning to re-use your original 74 intake manifolds (and I see no reason not to), you will not have holes on the carb mounting face. With that in mind... Yes, you can use any of the carb insulators, including your original 74 insulators. There were three versions of those insulator / spacers: 1) 70 and 71 uses insulators that are square-ish and thick. 2) 72 insulators were thick like the previous years, but they are no longer square. Now they are taller than they are wide. Also, they have holes in them (for the water passageways between manifolds and carbs). 3) 73 and 74 spacers were the same shape as 72 (taller than they are wide), but they are thinner and don't have water holes at the bottom. The only question is do you want thick or thin? The reason they went to the thinner insulators in 73 was because they were running out of room between the air cleaner and the side wall of the engine compartment. If you've already got a set of the thin ones there, you could just run them. If for some reason you want to replace them with a thicker version, then you could do that too.

-

Carbon Canister to Fuel Tank Hose

They used restrictors like that in several locations over the years. Most times added later as an "afterthought" fix for some sort of issue they were encountering. And I believe they were put in to slow a signal down or smooth a rough one out. Sometimes they talked about the little restrictors, and sometimes they didn't. Small detail that sometimes didn't get any press attention. I don't know what the specific purpose is for the one you found there. I would expect that to already be a smooth signal, so I don't know. What year are you working on?

-

260z round top conversion: a couple questions

Let's do this a little bit at a time. First, lets talk about intake manifolds... In one year, and in one year only (1972), they passed water between the intake manifolds and the carb bodies. So the 72 manifolds have water holes in the face where the carb mounts. None of the other years have those holes. Earlier round top manifolds don't have those holes, and later flat top manifolds don't have those holes. So as long as you don't have holes in the surface where the carbs mount, you can mix and match any carb with any manifold. Does that make sense? It sounds like none of the intake manifolds you have holes where the carbs mount, right?

-

window defrost grid

The math looks good to me. That said, however... I cannot attest to any potential GIGO factors with the original inputs though. What's the fuse value? And they run a relay for the defroster, right? I've seen them switch 3A loads without a relay... Seems a little fishy.

-

window defrost grid

The bend in the hatch glass is subtle enough that I wonder if someone who knew what they were doing could silk screen that after it had been formed. I'm no silk screen expert, but I wouldn't be surprised if they could deal with that gentle bend. In my distant work past, I was a customer of several membrane keyboards and that technology typically uses a lot of silkscreen processes. I've never done it myself, but my employer bought lots of them and I got closely grazed by much of the technology.

-

KONI Sports for Classic Z's

Good to know that I'm not alone. I was under the impression that I was the only one who found it impossible to decipher instructions like that. I wonder if people in other countries have the same problem. I think those icon based instructions were supposed to make them easier to understand in all languages. I think they've done just the opposite.

-

KONI Sports for Classic Z's

Agreed. I enjoy making little stuff like that that I get to use. You might not have the right size tubing to use, but you've got a lathe. Just drill out the end of some solid stock and oval-ize it. With a few crude calculations, I think you could get close on the first try and then hit it on the second or third. If you've got tubing close to the right size but a little small, you could bore it out. And then to make it looks "proper", glue on an old screwdriver handle* on the other end. Or turn a nice wood handle on the lathe and use that. You'll be the envy of all the other Koni-ites. * You know the one... The one that's all rounded off and is pretty much useless as a screwdriver. Heat up the metal until it melts the handle a little and then yank it out. Haha!!

-

Drivers side front tire negative camber

I don't know if it's the same issue, but it's not the first time we've seen a bent strut assembly: https://www.classiczcars.com/forums/topic/60602-front-suspension-and-tire-clearance-problem/

-

I've been looking for a project

I'm no suspension guy, but my thoughts on the order of events would be to do the back first. Why? Because there are some hurdles to overcome like stuck spindle pins and bearings pressing. "Harder" from that standpoint, but "easier" because you don't have to an alignment after.

-

KONI Sports for Classic Z's

Yup. That's typical galling. Here's some links that talk about such things. Some of these even specifically call out stainless nyloc nuts: https://www.boltdepot.com/fastener-information/Materials-and-Grades/Thread-galling.aspx https://www.anzor.com.au/blog/what-is-stainless-galling https://www.westfieldfasteners.co.uk/Ref_Thread_Galling.html The bottom line is usually... Use lots of lube and go slow. And even then, don't do stainless Nyloc on stainless threads unless you're an expert. Now I don't know if Koni's damper shaft is stainless, but it might be. Did they supply the stainless Nyloc nuts with the dampers? All those parts were in the same box? Seems they would know about the risks. Especially by now. So is the yellow tip the thing that you spin to change the damping? Seems like you could just take a small piece of metal tubing and judiciously "crush" one end to ovalize it and allow it to grip that yellow tab. If that's the case, it would be an easy way to make a longer tool to reach the adjuster.

-

KONI Sports for Classic Z's

LOL. If I had a nickel for every time I've heard that......

-

No oil pressure after rebuild

Will do. I'll put something together.

-

No oil pressure after rebuild

Yes, it is to be expected. That's normal for the signal going out to the sender units (Oil, fuel, and temp). They are pulse width modulated. I don't think it directly pertains to your issue (which sounds as if it may be a non-issue after all), but if you or someone else wants a description on how the gauges work, let me know and I'll put something together.

-

KONI Sports for Classic Z's

Stainless Ny-locs are a dangerous thing, especially if you aren't aware of the issues. Stainless is prone to galling and that's exactly what happened to you.\ If they ran a stainless nyloc onto a stainless shaft, they were asking... No, wait... BEGGING for trouble.

-

KONI Sports for Classic Z's

No, he's saying it "bottomed out" on the metal at the top of the strut tower and wouldn't reach down deep enough into the hole to get onto the adjustment spinny. He had to "lengthen" the tool to reach deeper into the hole by removing some of the finger grip knob portion from the underside. I don't think he was ever intending to leave it under the plastic cap, it was completely unusable as originally designed. Couldn't adjust the strut at all. Of course, I'm trying to translate for someone else....... @AK260

-

window defrost grid

I would guess they silk screened it.