Everything posted by Captain Obvious

-

New mustache bushing updates?

I firmly believe there are other options for rubber moustache bar bushings out there but the problem is figuring it out. The original bushings pressed in (lightly), and then were swaged over for permanent retention. I bet a workable solution would be to use a new bushing of "similar, but slightly smaller OD" than the original and press the new one into the remains of the old bushing. Kinda like what you do with poly, but do it with a new rubber bushing instead. All that needs to be done is for someone to find that "similar, but slightly smaller bushing". I saw some pics of Miata diff mount bushings that looked interesting... Anyone have a Miata that could measure some bushings?

-

Brake Booster Rebuild Help

I've seen a couple other owners use rods with some small imperfections in them (what it sounds like yours has), and they were OK. Mine had been bathing in brake fluid for a couple years and was not OK. Haha! And small world... I lived in Lancaster for a year, and my brother lived in Venice for maybe 10? I also lived in Pittsburgh for a couple years. We have probably run into eachother in the past!

- 1970 HLS30-06521 Re-Restoration

-

fuel guageOHM's readings

Haha!! Agreed! After you clean that up, yours should go to 11!

-

Brake Booster Rebuild Help

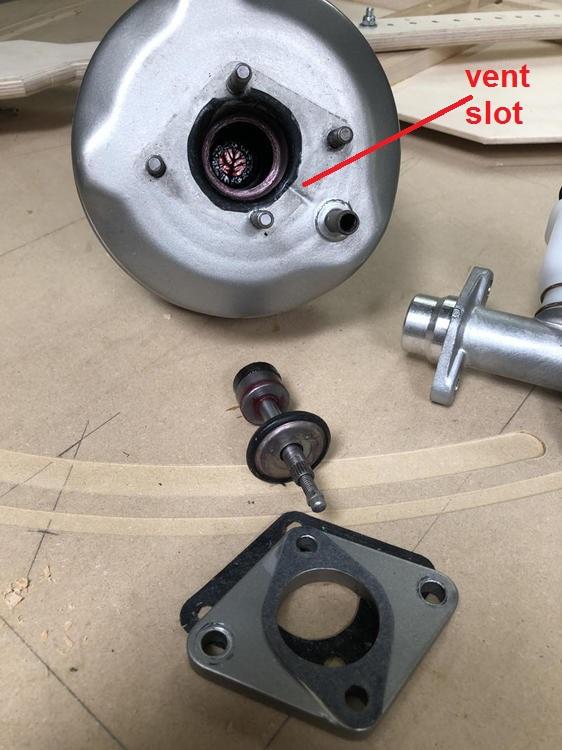

If the surface of the rod isn't all pitted with rust, it should seal pretty well. In the area where it matters, yours looks pretty good. So about the vent passage... Are you sure the gasket you put on there isn't compressed into the vent and blocking it off? I'm beginning to think that there is NOT another passageway on the adapter plate or the back of the master cylinder. That slot may be the only vent?

-

fuel guageOHM's readings

Ewwwwwwww!!! That's got to be worth a quarter tank at least! Maybe a third! Woof! That's a perfect example of why I say... "If you have a couple moments of free time with nothing to do, clean some connectors on your old Z car."

-

Brake Booster Rebuild Help

ToolBoy, You can see the vent passage in one of the pics you previously posted: I thought there was slot in the master cylinder or adapter as well. I looked for pics, but unfortunately don't have any that would help there.

-

Brake Booster Rebuild Help

In reality, you don't ever want to draw a vacuum against the back of the master cylinder. In fact, on the original system, I there's a hole to prevent just that. You shouldn't block that hole (like with a gasket or something). and because there IS a hole there, the bolting of the master cylinder to the booster will do nothing to retain vacuum.

-

Brake Booster Rebuild Help

No, it will not hold vacuum without that front seal. If that seal is not in place, it's a direct link from the vacuum port to that hole.

-

Crank snout turning nut

The Evaporust stuff won't work on generic corrosion. It only works on "real" rust (iron oxide). It a chelating agent and I'm no chemist, but from what I've read It works by actually dissolving the iron oxide and putting it into solution. So if the problem is real rust on the steel cylinder walls and steel rings, it might help. But if the problem is white corrosion on aluminum pistons jamming up the works, then I don't think it will do much to help. The reason I was asking about the oil pan is that evaporust and similar stuff is water based and will (hopefully?) run past the rings and end up in the pan. You might not want a bunch of tablespoons of anything water based in the pan.

-

Crank snout turning nut

I'm anxious to know if it fits!! You mean I have to wait until the weekend??? I was also thinking about your frozen motor dilemma... I was wondering if a couple tablespoons of evaporust in each of the bores might help break down any rust between the walls and the rings. It's aluminum safe, so pistons would be OK. Do you have the oil pans off?

- Crank snout turning nut

-

Crank snout turning nut

LOL!!! You don't even want to know! So I decided to go ahead and make it square. I have no idea where the key(s) ended up on your blocks and I was worried that the two flat design would always put the flats in an inconvenient location for putting the wrench on it and getting leverage. It's 2.4 inches square, so your 2.5 wrench should fit fine.

- 1976 280Z Restoration Project

-

Crank snout turning nut

After a completely unprofitable amount of time, I have this: I mistakenly made the slot a little wider than I wanted. I was aiming for .210, but I got about .230. I think it'll be fine for what you're trying to do. Just don't misinterpret the initial backlash "take-up" for movement of your crank. It should go out Monday.

-

What distributor do I have and is my tach broken?

73 was the last year for points. The 74 260 was the first year for electronic ignition. Oh, and Zed Head types faster than I do.

-

Staked Nut and Steering Gear

That means "Don't cut off the staked in portion before taking the nut off. Just put a big enough wrench on it and spin the nut off. The staked over portion (caulking) will bend out of the way as the nut comes off." That's what they meant, but don't believe it. People have done that and it messes up the threads. Not sure why they recommended that. Maybe they thought it was less risky than trying to cut off the staked over section and accidently cutting into the threaded portion? In any event, even though they said to leave the caulking in place... Don't.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

Yeah, then yours probably petrified and fell off some time in the past. And for the guys with the O-ring style built into the valve cover, I guess that's the older style. according to the documentation, they changed over to the newer style in 71.

-

Crank snout turning nut

I was only worried about elbows down, and I washed thoroughly with dishwashing soap* in the sink shortly after the event. I heard some long time ago that you have about 45 minutes minimum to get that stuff off your skin and you should be OK. It was about thirty minutes before I got washed up, and with no issues today, I think I'm fine. The only thing bothering me now is my thumb is still swollen and hurts way more than it should from such a small wound. I think I broke the tip of a thorn off inside. Here, have some roses they said. They're beautiful, they said. Haha!! *We usually use Dawn, but couldn't get it last time we needed soap, so we're currently using Palmolive.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

Right. It's easy to mistake it for part of the cap. Here's some pics. Cap, as it's normally seen: Close up of the seal in-situ. Looks like all one piece: But in fact, it's not. Used a thin blade to get a little separation and get things started, and the seal comes off. Note the step on the seal and the recess on the cap. Speculation on my part, but I bet the earlier seals (with the different part number) didn't have that feature: And here's a close-up of the cap with the seal removed. You can see the recessed area for the step.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

I have one on my cap. It's a black washer and if you poke at it with a screwdriver tip you can see that it's not quite as hard as the plastic cap, but it's pretty hard. Maybe 1/16 inch thick? ID is a snug fit on the threads, and the OD is about the same size as the raised boss on the valve cover? I don't know how compliant they were when new so I don't know if it was always that hard, but I suspect it was slightly more compliant years ago. Every Z I've messed with has had one. I think you might just be not realizing it's there. It's really easy to mistake it for "part of the cap". I'll take a pic tomorrow if someone doesn't beat me to it.

-

Crank snout turning nut

Gotcha on wanting to keep the engine together for now. I'm continuing to work on the nut as time allows. I spent almost all of today outside trying to injure myself with lawn and garden equipment. Couple minor flesh wounds. Won't know about poison ivy until tomorrow.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

Thinking about it a little more, there is also the possibility that yours got so completely petrified that it cracked into pieces and fell off sometime in the past.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

Yes there should be a seal on the cap, and I bet you DO have one there. It's just hard as a rock from heat and age and it looks and feels like it's hard plastic and part of the cap. But in fact, it's a separate piece. #40 GASKET-OIL FILLER CAP - 15270-78500 Note that the early cars (through mid-71) used a different number, but from that point on, everything used the 15270-78500.

-

Crank snout turning nut

Oh, and after I see that busted damper, I'm thinking that the more meat I leave on the "nut" the better. In fact, how about I skip the flats completely and you just weld a pipe to it? I'm concerned that maybe your adjustable will smear the flats. It's currently a little over 3" OD and maybe 3/4 thick hockey puck. Very thick walls at this point. The weak point is probably shearing the key off.