Everything posted by Captain Obvious

-

240Z D hubcaps ... reproduction?

My BS detector goes off loud when I see those too although I don't have any specific tell to point to that is a clear indication they are repros. I do worry that it seems the people who are making these are simply getting better at fixing their mistakes and making the repros harder to distinguish from the original versions. I suspect the chatter here pointing out the differences is allowing them to monitor this thread (and maybe others like it) and use the info within to improve the parts. Double edge sword... Better repros that are virtually indistinguishable from the originals are a good thing. But if they are sold claiming to be NOS parts made by the original manufacturer, it's a lie and should not be allowed.

-

F54/P79 Swap Project

And just in case everyone isn't already tired of talk about pulling main bearing caps, here's what I did for the remaining (2, 3, 5, 6) caps. I grabbed some steel rod just slightly larger OD than the bolt holes through the caps. Turned them down a small amount so they just barely slipped into the bolt holes. Here's the pair of them, You can see the machined ends at the bottom: Slip the pair of them into the holes like so: And when you squeeze them together, they pretty much lock into the holes giving you a handle to wiggle a little bit and easily pull the caps up off the block: Sure, I could have just tapped them with a hammer and used the original cap bolts to wiggle the caps off, but for ten minutes of invested time, now I've got handles.

-

F54/P79 Swap Project

This was my experience pulling that troublesome center main bearing cap (#4 with the thrust bearing surfaces). The chunk of scrap I used to make the puller for the rear main #7 (above) wasn't long enough to span across the width of the block, so I couldn't use it to pull the center main. If I had something longer laying around that was thick enough, I could have made one puller that would work for both mains #7 and #4. But I didn't. However, since cap #4 is so much thinner and easier to pull than #7, I can get away with something thinner. So for cap #4, I used a simple length of angle iron with a hole in it for a jack bolt. Use a couple pieces of scrap wood to straddle it off the oil pan mounting surface and it looks like this: Straddle the bearing cap, screw in the jack bolt, and then use a ratchet to crank the nut down against the "fixture" to pull the cap off the block: Couple turns with the ratchet and #4 cap pops off easy-peasy:

-

280z sitting voltage?

The basic difference is the ability to really tell what's going on with the charging system. For example, consider the following... You're driving along, and all of a sudden, your alternator goes belly up. The voltmeter will still pretty much read the same thing because the battery is at full charge, but an ammeter would instantly start reading a negative charge condition (meaning that you're taking energy out of the battery instead of putting it in). Referring to the chart posted above in post number (nevermind, we don't have that feature anymore)... somewhere up above earlier in the thread, it shows that the battery voltage is only down to about 12.1 Volts by the time you have already taken half the total charge out of it. So with a voltmeter, it's possible that you wouldn't notice any problem until the battery has been drained down pretty far. But with an ammeter, it should never be on the "-" side of the gauge when the engine is running. If that ever happens, it's an indication of a potential problem. All that said.. .As SteveJ alluded to, it's just so much harder to install an ammeter in a system when compared to voltmeters. Voltmeters are hang on anywhere and are a snap to incorporate. And for that reason, the ammeter is almost extinct.

-

'71 temp sensor thread size

Perfect! Haha!! "Crank" that sucker in there!

-

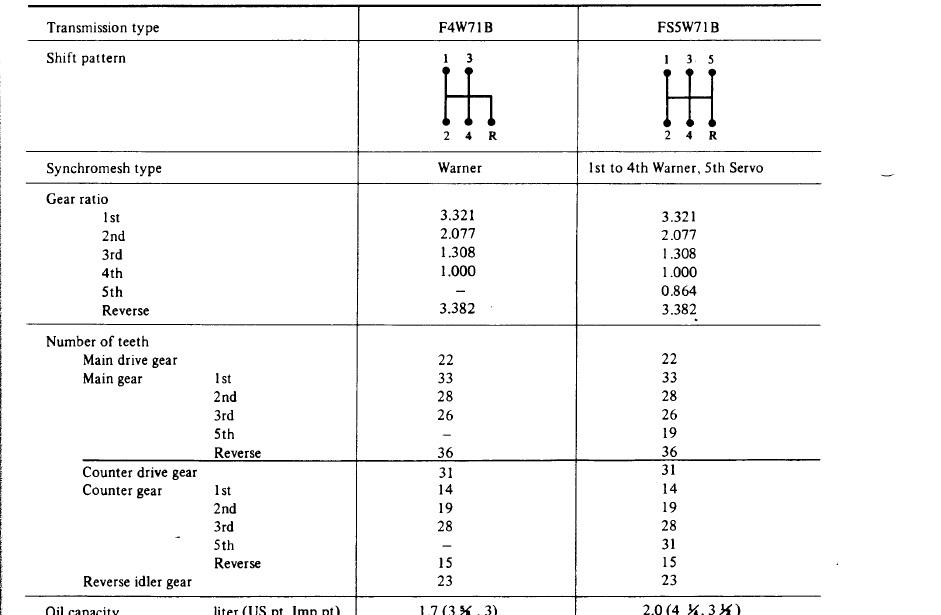

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Sorry... I'm baaaaaaack. But this time it's actually with some useful input! I just snipped this from the 78 FSM (MT-18). Not sure if the other years contained this info (assuming not, or you would have simply found it and not asked in the first place), but this should answer most questions about the gear tooth counts: In 80 they they started messing around with the ratios, but this should hold for everything up to and including 79.

-

280z sitting voltage?

One thing to keep in mind is there is significant parallax error when viewing the gauge since it's over there on the side and you're not looking at it square. I find mine "accurate when viewed from the driving position", but if I look at it "straight on", my battery voltage appears to be low. I've decided that since I'm most often looking at it from the driving position, I'm going to keep it that way. Makes me wonder if maybe they calibrated them like that on purpose.

-

L28 full rebuild assembly

Oh well. So my first salvo was a complete miss. I'll have a beer or two and see if I can remember where I read about that...

-

"The Orange"

What did you use for harness wrap tape? I redid my engine room harness a couple years ago and the stuff worked great, but it's a little too shiny. Too glossy. Not a big deal since I'm not doing a real resto, but always wondered if someone else turned up a better option.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Oh, and by the way. Just want to let you know that I do totally get it. If you slide the synchronizer onto "the first gear" to lock it to the main shaft for 1st, and you slide the synchro onto "the second gear" for 2nd, and you slide the synchro onto "the third gear" for 3rd... Then what would you call the gear that gets locked to the main shaft by the synchro when you're in fourth? I'm gonna stop talking about it now.

-

L28 full rebuild assembly

- L28 full rebuild assembly

LOL. I suspect you're not far behind me! Haha!! OK, OK... I'm gonna take a stab and say that @Dave WM was involved? Maybe?- FS5W71B Rebuild Thread - Tips tricks and discoveries!

I just took a quick look at the parts breakdown and they call that front gear the "Main Drive Gear, and it's mate is "The Counter Drive Gear". 6 GEAR-MAIN DRIVE GEAR-COUNTER DRIVE The do, however, number the remaining gears: 19 ASSY-GEAR,1ST MAIN S 20 ASSY-GEAR,2ND MAIN S 22 ASSY-GEAR,3RD MAIN S I probably should have checked first.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

I don't believe I'm misconceived or confused. I've not been inside a Z tranny, but your description of operation is exactly how other transmissions I have been inside have worked. I guess my only confusion is why are you calling it a 4th gear pair? Does Nissan refer to that main front driving gear as the "4th gear"? And my point is that there is no 4th gear pair because when you're in 4th no power is being put through any gears when you're in 4th gear. In fact, you could grind all the teeth off that front gear completely and 4th gear would still work. It doesn't need a pair. it's just semantics really. You clearly know exactly what's going on inside. I'm just protesting the implication of the naming convention I guess.- L28 full rebuild assembly

I didn't pay complete attention (because it wasn't my horse in the race), but I remember someone sent injectors out for cleaning and then when they came back, they didn't use them for a "while". And after sitting, some of them didn't work right? Something like that? Theory being that they rusted up inside over the delay time. I don't remember if that was on this forum, or someplace else. May not have even been a Z. But I remember something about that.- '71 temp sensor thread size

Yeah, that's a nice plug. Way nicer than using a normal bolt. The shoulder provides a much better sealing surface (as it was intended). So, is the head metric? Or is it (like so much of the other "metric" stuff available here) metric threads, but an English sized head (like 1/2 inch)? Also, I wouldn't use the O-ring. I'd use an aluminum or brass crush washer designed for that. I don't think the O-ring is the right seal for that type or twisting/crushed sealing application. That O-ring was probably designed for an application that had a counterbore cut in the female portion as a groove to hold the O-ring. It's nice that it came with, but I wouldn't use it.- 280z 3D printed fuse cover and other parts.

If you're going to order some stickers from a pro, PM me first. We might be able to work out a split cost.- '71 temp sensor thread size

I like those plugs. Are they flat bottoms? Like made to be used with a crush washer seal of some sort?- FS5W71B Rebuild Thread - Tips tricks and discoveries!

I've got one listing sheet that I "found on the internet" somewhere, but I don't like the numbers. Doesn't look right to me so I'm reluctant to even post it. Got a question though while I'm here... You said you want to know the "4th gear tooth counts". My understanding is that 4th gear doesn't HAVE a count. I've never been inside a Z tranny, but with the others I've been inside, it would be straight through with the input shaft locked to the output shaft. All the counter gears just coasting along for the ride. None of the intermediate gear counts matter at all. Is the Z tranny not like that in 4th?- '71 temp sensor thread size

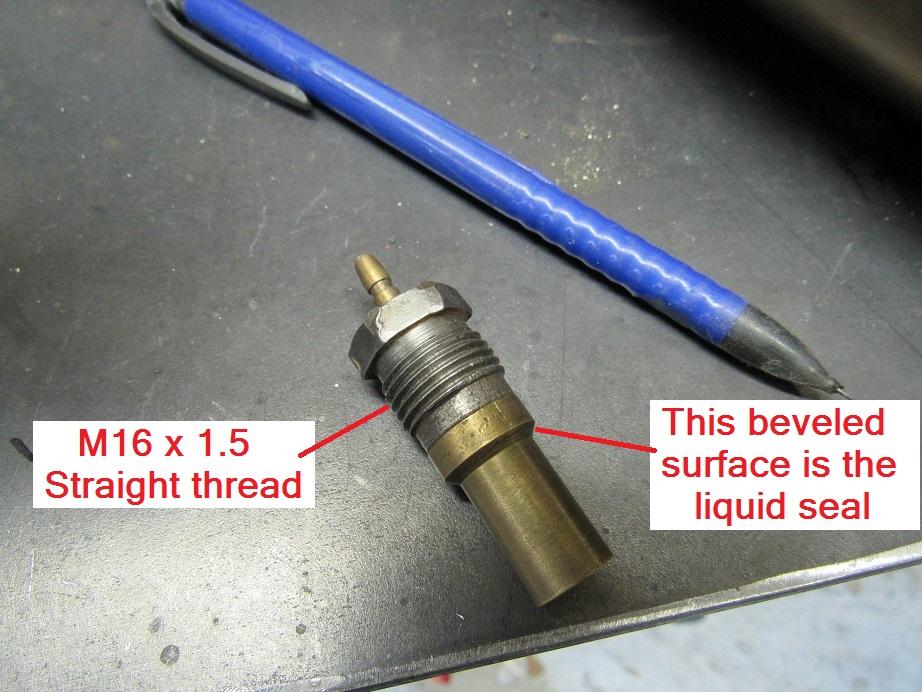

And although nobody asked (rarely stops me), here's some additional info about those sensors. The original sensors are actually two pieces. A steel threaded portion and a brass sensor portion. The steel part uses a straight thread and the reason they can get away with a straight thread (not tapered) is because that's not what holds back the coolant liquid. The liquid sealing surface actually has nothing to do with the threads. The liquid is sealed by the small beveled edge further down the sensor. Taking liberties with Granny's photo: Some of the newer aftermarket sensors are all one piece brass like the below. Note that the O-ring does not hold back the coolant. All it does is keeps dirt and junk out of the threads. The same beveled surface is what keeps the coolant in:- '75 280z #6 cylinder acting weird

- 280z 3D printed fuse cover and other parts.

Gotcha. So the traditional options are silk screening and pad printing. I know very little about either one and have never done either personally. Have you investigated someone who's business is to make stick-on labels? This should be a simple one for them.- 280Z early 5-spd 1st gear

I've never been inside a Z transmission, let alone an early one. But just because it's been 19 hours and there's been no action... So what is it I'm looking at here? Is that the 5-R section of the trans, or is that an unsynchronized first gear? (Did they use an unsynchronized 1st gear version on the trucks of the same era?)- 280z 3D printed fuse cover and other parts.

Actually it wasn't that glamorous. It was actually black printing on a white background, but was done in reverse so the lettering was the (white) unprinted portion. If I were doing this, I would change the design so that the lettering is recessed into the fuse block cover. Then when the printing was done, I would slather the whole top surface of the cover up with a thick white paint, making sure it got down into the recessed lettering "divots". Then I would sand the whole face carefully on a flat surface with some fine grit sandpaper. That would do two things. 1) Take the paint off everywhere except the recessed lettering, and 2) take the printing lines off the top surface of the cover and make it look better because it's smoother. Only problem is... It's a different cover printing for each different year.- Dead batteries

I suspect the only thing they would be good for is the core return on a new battery. Lead-acid batteries don't like to be taken down completely dead and usually suffer permanent damage. Probably shorted cells internally. - L28 full rebuild assembly

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.