Everything posted by Captain Obvious

-

Dead batteries

I suspect the only thing they would be good for is the core return on a new battery. Lead-acid batteries don't like to be taken down completely dead and usually suffer permanent damage. Probably shorted cells internally.

-

1978 5-speed transmission Tail-Housing Removal?

How about something like this? https://www.amazon.com/Mayhew-Pro-37019-Seal-Puller/dp/B008M238HU?ref_=ast_bbp_dp I've got something similar from HF, but I can't find it on their website.

-

1978 5-speed transmission Tail-Housing Removal?

Nice. I was sure you could come up with something! I've got some small suggestions to make it better now that proof of concept has been successful, but none of that matters until you decide to make the next one. Good work! I'm happy that this is one of those "difficult Datsun jobs" that I've never had to deal with!

-

Rust Advice 78 280z

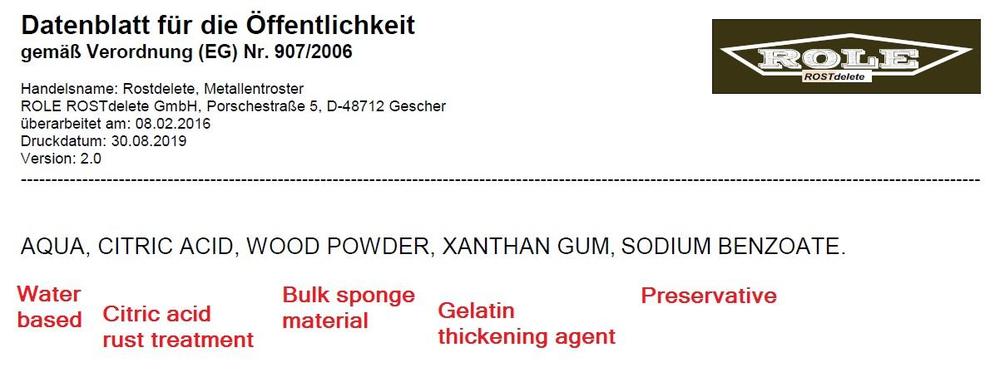

Gotcha. Shows what I know! LOL. So all you need for a proof of concept test is a citric acid based thixotropic paste. I suspect the finer the sawdust, the better, and (again, for proof of concept), don't know if you need to spring for xanthan gum. That stuff is a lot more expensive than corn starch (which you already have). Cooked corn starch slurry (cooked to activate the corn starch), with citric acid added. Only thing I'm not sure about is the reaction between the starch and the acid. I spend a fair amount of time in the kitchen, but I'm a little rusty* on which thickening agent to use in which application and I'm not sure if there will be compatibility issues. I do remember there are some restrictions on which starch to use when preparing a citrus fruit based dessert, so I'm assuming those restrictions would apply here. Could maybe use plain ol' gelatin as a thickener if corn starch isn't compatible? Maybe put in a little propylene or ethylene glycol to slow down evaporation? *See what I did there?

-

Rust Advice 78 280z

Honestly I'm not sure any garage chemistry is even warranted. My read on the whole thing is all that stuff is (is) a rust converting acid suspended in a bulky spongy gelatinous base material that slows down evaporation. The preservative is necessary because the citric acid will harbor critters over time and "spoil" (probably smell bad and lose effectiveness). But the point is.... It's a rust converting acid in a gelatinous bulk material to slow evaporation. I believe there are lots and lots and lots of phosphoric acid based materials on the market available at this side of the globe. My (own untested) suspicion is that I bet the phosphoric based stuff would work better, but is less safe to use and potentially worse for the environment. I suspect the citric acid based stuff is uber-safe and all that. From the list of ingredients, it looks like you could eat it. But that doesn't mean it works better, and in fact, most times the worse something is for you and the environment, the better it works. Is there some reason people would believe that citric acid based compound would be more effective?

-

Rust Advice 78 280z

-

1978 5-speed transmission Tail-Housing Removal?

Snuggles.

-

1978 5-speed transmission Tail-Housing Removal?

I was thinking the same thing when I was reading about the difficulties of getting that pin out. Seems like it should be a relatively simple matter of pushing that pin backwards using the shaft as the "anchor" for some kind of device to hook on*. In fact, if the large end of the pin (the non threaded end) is not proud of the surface on the fork casting, you wouldn't even need a recess for the pin to press through. Since it's tapered, all you need to do is break it free a little and it should move much easier after that. * Proof is left to the student?

-

Removing Intake Manifold Heat Shield

I suspect it was the cussing. That sometimes works for me too.

-

What are the facts about 280z ECU compatibility and differences

LOL! The IC's have numbers on them, but there's no info (that I can find) anywhere about what's inside. My assumption is that they are parts made by Hitachi for use only inside Hitachi produced devices and they didn't publish datasheets for them outside their own business. So you put a lamp in place of one injector and it blinked. That tests one output transistor. Can you move the lamp around to the other injectors and make sure the second output transistor is "working" too? If the wiring harness hasn't been messed with, I believe the injectors are grouped 1-2-3 and 4-5-6. You can pull the ECU off the harness and Ohm out the wires to the main ECU connector if you have to. As for the altitude compensations and stuff like that... The cars that did not need that stuff (non CA?) simply did not have them installed. My assumption is that the ECU defaults to "normal" non-altitude corrected if the other stuff is just left as no-connects. In other words, I strongly assume that you can just leave all the altitude compensation pins unconnected and it should work like a 49 state version.

-

F54/P79 Swap Project

My build buddy hit the PCV screen holder screws with an impact and said they came out easy-peasy. Thanks for the info guys. On another topic, this was my experience pulling that troublesome rear main bearing cap. I made this little puller adapter contraption from a scrap parts I had laying around. Riddled with extra holes from previous fixturing and holding uses. Anyway, couple holes and some threaded rod: Put it on the rear main cap and run the three threaded parts down into the holes in the cap. The two smaller threaded parts get threaded into the oil pan mounting holes while the larger part goes into the other threaded hole in the cap. Put a couple washers under the puller as jacking points and then run the nuts down against the puller to lift the cap out. It's not pretty (or symmetric), but it's what I had laying around. When you run the nuts down, it pulls the cap out a little. Keep stacking washers and repeating the process until you have the cap off: The FSM uses just the one larger threaded hole, but I found the bearing cap tends to cokk sideways as you pull it. I found I could keep the cap even and pull much straighter out if I used the oil pan mounting bolts as well as just the traditional puller hole.

-

Best Captain Obvious so far

Hahaha!!! I saw that commercial a little while ago. Loved it.

-

L28 full rebuild assembly

Consider it done. I'll put a set aside for you.

-

What are the facts about 280z ECU compatibility and differences

And about that HybridZ page... "If I remember correctly... The pics are wrong. The resistor designations are non-existent. And there's talk of a lamda sensor. All that spells different ECU."

-

Crankcase to PCV Valve Hose

Electrically conductive coatings can be measured, but depending on the style of coating, it might not be as simple as sticking your generic VOM leads into it. If it's intended to be "static dissipative", it might be a high resistance. In the MegOhm range. And in that range, the resistance through your body might be enough to get a reading on the meter, so if you're touching the leads (or what you're measuring) with your fingers, you won't know if it's the coating, or you.

-

What are the facts about 280z ECU compatibility and differences

I've never seen a schematic for the entire ECU. I've reverse engineered a little bit of it (very little). One of the sections I DID do however, is the output transistor section. Pretty self explanatory. I'll see if I can dig that up.

-

L28 full rebuild assembly

I've got a spare set if you need one. I had zero, so I put out a request a little while ago that was generously answered by @240260280. Then shortly after his gift set arrived, I lucked into a second set in a box of misc Z parts off craigslist. So now I have two sets and would happily send a set your way with the next shipment headed your way. But if I know you, the new set is already on it's way to you.

-

Crankcase to PCV Valve Hose

Sorry... I've hear that the silver coating is ELECTRICALLY conductive. I believe the belief was static dissipative or spark prevention? Apologize for the confusion.

-

Restoration of BringaTrailer 240z - HLS30-35883

LOL!

-

What are the facts about 280z ECU compatibility and differences

It sounds like your A11-600.... unit has a problem. My first WAG would be a blown output transistor and you're running on three cylinders. You should be able to check those big TO-3 buggers in-situ. They're Darlingtons, but you should be able to check them with the ol' Simpson.

-

Crankcase to PCV Valve Hose

I've heard the belief that silver paint is special because it's conductive. Haven't done a lot of research though, but "I read it on the internet".

-

L28 full rebuild assembly

Cool. So you just verified that the ZX pick-up tube fits with the Z oil pan, right?

-

F54/P79 Swap Project

Thanks guys. I'll hit them with a little heat and try an impact driver. I haven't really put a lot of grunt into them yet because I was worried about fighting thread lock. Keep you posted! And in the meantime... Here's some catch-up pics. This was my experience popping that troublesome front expansion plug. I made this little adapter contraption for my slide hammer: Carefully drilled (making sure I did not drill too deep) and tapped a hole into the expansion plug to accept the adapter: Thread on the slide hammer and with a couple taps, out pops the plug: Don't know if it would work on all attempts, but so far, I'm batting 1000 at two for two.

-

F54/P79 Swap Project

So I've been slowly working on the two F54 blocks here and I've got a question, The two Phillips screws that hold the PCV vent baffle screen into the block... Mine aren't coming out easy and I'm wondering if they used thread lock on them. Anyone who has taken those out have trouble with them? Last thing I want to do is snap one of those off in a newly painted block @GGRIII 's in front and mine in the back: We used different paints on our blocks. I like mine better.

-

L28 full rebuild assembly

Well I know from holding the two of them in my hands that the stock ones for the ZX are different than the ones from the Z. The one for the ZX is a little longer and comes off at more of an angle towards the back of the engine (which makes sense since the sump is in the rear). There are pics on ebay of both styles, but without them side by side, it's really hard to see the differences. Looking at the oil pans though, the holes down into the sump look like they're pretty much in the same spots, so I don't know if you can actually get one style to fit into the pan that it wasn't designed for. That link to zcardepot seems to indicate that it's (at least possible) to share the same pickup tube on all years 70-83, but that may be an aftermarket difference from stock? In any event, if you've got the ZX pickup there, should be easy enough to bolt it on and see if the oil pan will fit into place.