Everything posted by Captain Obvious

-

Leaking Heater

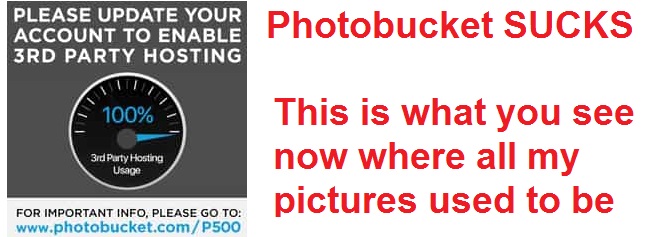

Yeah, that was me... Here's the thread, but it's mostly useless because Photobucket SUCKS: http://www.classiczcars.com/topic/56726-heater-core-alternative-escort-core-into-260280/ Used to be loaded with pics, not all you get is this:

-

Rear bushings

When I was messing around with my diff, I replaced the original mount hardware with socket head cap screws coming up from the bottom instead of the original hex head bolts. Here's the thread where I was talking about all of it. Thread is pretty much useless now because all pics are dead because Photobucket SUCKS, but here it is anyway: http://www.classiczcars.com/topic/55955-my-new-diff-mount-and-strap-project/ The bottom line is if you go through the effort to take the front diff mount off, I would use different hardware when you put it back on. Here's a couple pics showing the idea:

-

Photobucket Rant - They SUCK

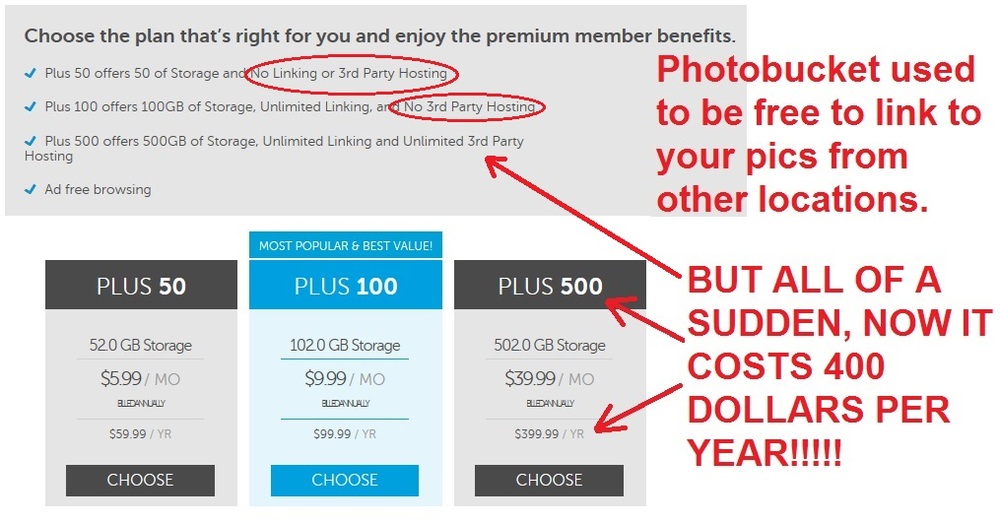

Patcon, I know I could put the pics here on Mike's site, but many of what I have out there isn't specifically Z related. For example, the last pic I posted was my liquid level manometer that I was using for my motorcycle carbs. While it isn't Z car directly related, the topic came up, and you can even see a corner of my Z in the pic. I had that pic posted on a cycle forum and I would have to host it in multiple locations instead of just one and linking to it when appropriate. It's reasons like that which make it desirable to have an independent picture host that I can link to. Just not one that blindsides me with $400 per year!!!!

-

Photobucket Rant - They SUCK

Many people believe that Photobucket is hitting up people who are approaching their storage limit. Well I'm nowhere near my storage limit. I'm at about 10% of my allotted capacity. I'm nowhere NEAR the limit. So that rumor isn't true. The whole thing stinks like questionable business practices. After you have upload a picture, they present you with a number of link buttons to get the picture address in a couple different formats: One of these buttons called "Direct", gives you the URL address direct to the picture. This allowed you to use that link address to do what I did... Post it elsewhere. There's even another button called "Image", or something like that, which even puts the tags onto the address for forums that use that kind of nomenclature. You use that button if you don't want to put the IMG and /IMG tags onto the picture address yourself. So why is this noteworthy? BECAUSE THEY ACTUALLY PROVIDE EASY TO USE SHORT CUT BUTTONS TO ENCOURAGE YOU TO DIG YOURSELF INTO A HOLE THAT YOU NOW HAVE TO PAY FOR!!! In other words... They have been providing these free easy to use features forever. You use these features and get yourself mired into a place that is very hard to get out of, and then AFTER you have dug your impossible to get out of hole, they bait and switch you and tell you it'll cost $400 per year to save your butt. I've been looking at their ads for years. Photobucket gets paid by other companies for the right to have their ads pass through my eyeballs. And as incentive for me to look at their sponsors ads, they host my photos. That's the deal. I look at the ads, they host the pics. Then they decide they aren't getting enough from one end and hold my pics and years of built up threads as ransom? Almost as if they had this planned for a long time because they knew it would be impossible for people like me to recover from the change without paying. Unfair business practices?

-

Photobucket Rant - They SUCK

All my picture links are broken. All those threads with my pics in them are now pretty much useless because of Photobucket. They suck. I've been using a free Photobucket account for years. All these years, I've uploaded pics to their site and then linked to them from other places (like this forum). Well, guess what... They just made a changed their policy and removed the ability to link to pics from other locations. They call it "3rd party hosting", and you can no longer do it from a free account. In order to have that ability, you must upgrade to a higher level pay account. In fact, in order to have the ability to do "3rd party hosting", you have to upgrade to their "Plus 500" level account. Now get this.... The cost for the pay account that will allow this linking is....... $400 dollars per year!!! So, I'm really sorry, but my pics are gone. If anyone has a specific thread that they're looking at and want the pics, I'll see what I can do about hosting them somewhere else, but I have so many that there's no way I can wholesale move everything at once. Sorry...

-

Rear bushings

If you removed the spindle pin lock bolt and got the pin to turn that easy, then you're already more than halfway done with the job! The rest is gravy!

-

Seafoam spray through carbs ?

I haven't studied or used the stuff, but it sets off my snake oil alarm. Pour it into the gas tank. Draw it directly into the intake tract. You can even rub it on sore muscles. Puts tread back on worn tires. Cures whatever ails ya! More power to the people who believe they've gotten good results, but I just don't like the sound of it.

-

ZX alternator upgrade

Let's hope it's that simple. Wouldn't be the first time someone had to go back for another rebuild.

-

Rear bushings

Yeah, I have a 20T, and if you've got the room for it, that's what I would recommend. I was just thinking that a little 6T would be good to hide in an apartment closet. Hey, is that a hydraulic press in your closet, or are you just happy to see me?

-

The GREAT 2017 ZCON picture thread

-

Rear bushings

I get more use out of mine than I ever thought I would. I'm really glad I have one. Maybe try a little 6-ton HF A frame design? Light enough to store in a closet and pull it out when you need it? Not sure 6T is enough to do bushings though.

-

Deja Vu: 1971 Restoration

Cars don't talk back they're just four wheeled friends now.

-

Ignition drops voltage while cranking/starting

There should be enough fuel in the bowls to run the car for about a minute with no fuel pump at all, so... I'm thinking it might not be a fuel pump issue at all? By any chance, is the ignition coil power on the same circuit as the fuel pump? If so, I suspect lack of spark, not lack of fuel, may be causing the issue? If that's not the case, and your bowls are actually drying out between starts... I'd be interested as to why that is happening.

-

How much Current through Distributor Sensor Leads?

Q - How much current could you get from a metal star-wheel whizzing by an inductive coil? A - Infinite if the resistance in the loop is zero. Zero if the resistance in the loop is infinite. It's the Law.

-

Rear bushings

Good luck with the project. My results for my car were dramatic once I had redone the whole suspension.

-

ZX alternator upgrade

When you say that the needle is going stop to stop as far as the needle can move, are you saying that it is slamming back and forth from like +40A to -40A? If that's the case, then I doubt the problem is simply a loose belt. I'm thinking a loose electrical connection (shunt, fusible link, battery cable, something like that), or a faulty rebuilt alternator.

-

The GREAT 2017 ZCON picture thread

Zup, I'm glad to have been able to help you out with the tire~ Zedy, Just wanted to let you know that it was great to meet you, and I'm sorry that you had to take off before the banquet. If you would have been there, we would have had FOUR trophy winners sitting at the same banquet table. Glad you got a handle on whatever was going on with the allergy. I'm glad I had the chance to spend some time with you before you had to take off.

-

The GREAT 2017 ZCON picture thread

-

Rear bushings

Any hints? Yeah... Buy a hydraulic press. Even if you don't need it for the spindle pins, it makes easy work of removing the old bushings and installing the new ones. You know you've wanted one for a long time anyway.

-

How much Current through Distributor Sensor Leads?

I haven't measured it, but I suspect the current drawn by the ignition module is in the milliamp range. I suspect they used the gauge wire they did (for the red and green) simply because that's the smallest they used anywhere in any harness. I would be happy to defer to someone who has actually taken measurements, but my instincts tell me that you can use any relay you want without worry. I also believe an SPST relay to disable the circuit would be fine as well. Since those two wires don't go anywhere else other than the ignition module, you don't have to break both legs. In other words... It's a loop. And a loop with one break is just as broken as a loop with two breaks.

-

The GREAT 2017 ZCON picture thread

I wanted to say thanks for all of you for putting up with my calamities. I felt like death warmed over the first day I got there, and surely wasn't a lot of fun to be around. (For those of you who weren't there or heard any of the story, I blew out my back a mere 12 hours before I was supposed to get on the plane for ZCON, and almost pulled the plug on the trip due to the pain. Thankfully, I did not.) What really helped was when I hobbled to the show at the Oasis and saw the smiling gang of familiar and new friends. Friends that were clearly surprised that I made the trip. I tried my best to put on a good front that day. but I've heard from many of you that you could tell I was suffering. Just wanted to let everyone know that most of that is behind me now. I'm home, safe, and feeling much better. Not at 100% yet, but well on my way. I want to give a special shout out to my travelling partner Gary @GGRIII for pulling me along and picking up my slack. He took care of all my lifting the entire time I was there, pulled my bag through the airport for me, and even chauffeured me around the first two days as I laid back in the passenger seat of the rental car. I would not have been able to make the trip without him, and he deserves the credit for making this trip happen. I've got a number of pics that I will eventually post, but at this point I'm exhausted. Here's one that can't wait though:

-

Designing A/C System Using Other Cars Parts?

It doesn't spell it out, but they offer two systems... 1) What they call their "complete" system, and 2) what they call their "underhood" system. My belief is that the underhood system includes everything you need except the evaporator (and expansion valve), and the controls. I think it's got everything else, including the interconnecting lines.

-

Designing A/C System Using Other Cars Parts?

I've got a parts ZX here that I could scavenge parts from, but wouldn't that have the same parts availability and old technology issues as a stock Z system? I was thinking (hoping?) that something from a Sentra or something ubiquitous like that would be cheaper, more reliable, more efficient, and easier to find if I need another one. As a matter of fact, I've already got a stock 260Z mounting bracket and compressor. I was just thinking that I could do better?

-

Designing A/C System Using Other Cars Parts?

Thanks all. Jbond, I think I found the system you installed: http://autoacsolutions.com/store/products/1976-1977-1978-datsun-nissan-280z-ac-underhood-package/ So why is it that the Sanden 508 compressor is so popular? Is that a good one? I did some digging at rockauto, and clearly one of the stumbling blocks for slapping a different compressor on there is the belt configuration. Everything new runs the multi-groove belts instead of the old school V that we use. If the system was still under pressure, I would trust a compressor from a junkyard. I don't think I want to put in a used compressor though. That's something that I want new. So, if I can get a cheap compressor from a yard, I wonder how much I would spend on getting custom lines made up. Question is... If I use a cheap junkyard yard compressor, but spend real money for an evaporator and getting custom lines made up, would it have just about the same cost as buying one of the pre-packaged kits?

-

Designing A/C System Using Other Cars Parts?

Do we have any A/C experts in the house? My 77 280 came without A/C and I'm working on adding a system. I've got the interior stuff done and have turned my attention to the stuff in the engine compartment. Has anyone got any experience with using parts from a different vehicle and adapting them to the Z? I'm assuming the technology and compressor designs for the newer stuff (designed for R134) is better than the stuff from forty years ago. Newer, lighter, more efficient, cheaper? I could "relatively easily" fab up a mounting bracket to mount a different compressor where the stock one goes. Use a ubiquitous compressor from a Maxima, Civic, or Corolla instead of the stock one? How "matched" do the components need to be? Compressor, evaporator, condenser? Would it even work right to use a compressor that wasn't designed to be used with the stock evaporator and expansion valve? So what I'm asking here is.... Has anyone done anything like this, or am I on my own breaking new ground?