Everything posted by Captain Obvious

-

73 240 No spark

That all depends on the internal design of the ignition switch. Some of them are designed such that the power on the ON terminal drops out when you rotate the key to the START position, and some of them keep the ON terminal hot even when the key is in the START position. It's clear (from the behavior of the car in question) that he has a switch that does not drop out the ON connection, but in fact, keeps that connection hot even when the key is rotated to the START position. Depends on the car year and whether the switch is factory or has been replaced by aftermarket at some time in the past, etc.

-

73 240 No spark

HAHAHAHAHA!!! Perfect!

-

73 240 No spark

WOOO HOOO!!! Congrats!!! And yes... There's still the issue of the power not making it's way through the tach, but take victory where you can get it!!

-

73 240 No spark

Hmmm. Well I think we are hunting for two very different problems, so... My money is on corroded points that never make good contact for the first issue. And a bad connection to the tach, or identifying the wrong B/W wire in the harness as the one coming from the tach for the second. What does the winner get?

-

73 240 No spark

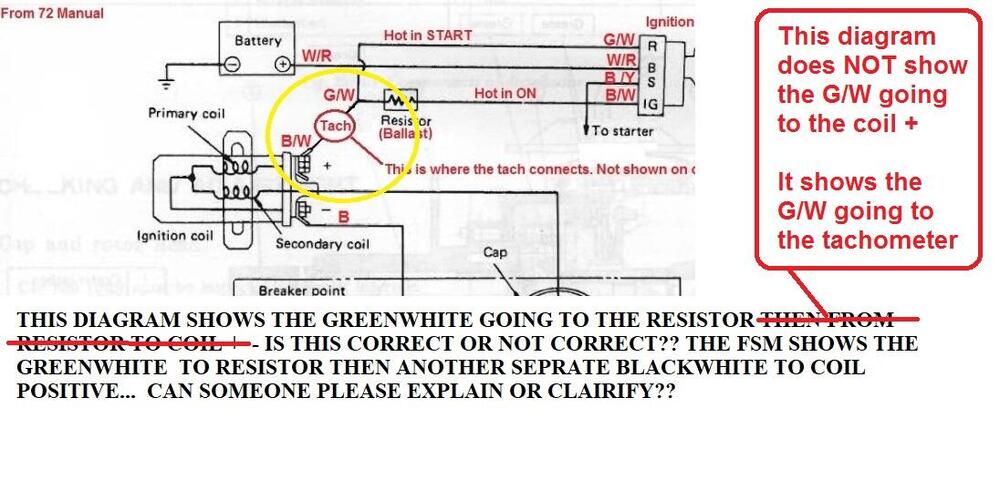

That's a great drawing showing the ignition system. With the line showing the firewall in there, it does an excellent job of illustrating why you only need one wire on each end of the ballast resistor and why you don't connect directly from ballast and coil. Shows how the other connections are made inside the harness. Thanks for posting that!

-

73 240 No spark

- Back Pressure Regulator Recommendations?

I'm still thinking you are looking tor a bypass style regulator. Maybe this helps? https://www.jegs.com/tech-articles/how-a-fuel-pressure-regulator-with-return-a-bypass-regulator-work/ Have you got any websites with descriptions of what you are calling a back pressure regulator?- Restoration of BringaTrailer 240z - HLS30-35883

Thanks for the details. Beautiful work.- Testing Pertronix Ignition Module

Seriously?? The technology to prevent that has been incorporated into modules for decades. Even the 74 260Z with the stock module has provisions to prevent that. Sheesh. Trying to save $0.10 worth of components??- Restoration of BringaTrailer 240z - HLS30-35883

Just picking nits, but should that have a branded fuel pump? Nikki, or maybe a Kyosan Denki? In any event, it's beautiful. Do you have a pic of the master cylinders (clutch and brake)?- Back Pressure Regulator Recommendations?

When you say backpressure regulator, are you talking about a bypass style regulator? Hoping maybe its a search term issue?- 1971 HLS30-14938 "Lily" build

The pedal should be bottoming out on the brake light switch. The switch has some adjustability, but If you're nowhere near the switch, there's an issue.- 280z Auto to 5 Speed swap-- Clutch pedal height

Right. At the top of the pedal stroke, you need to assure that the master cylinder returns to it's "at rest" position where the plunger is not pushed in at all. There is a valve inside the master that needs to be actuated when you let the clutch pedal up. If you have things adjusted with the rod too long, you run the risk of having that valve not open when you take your foot off the clutch. You can also cause a clutch riding situation by having the push rod on the slave adjusted too long, but that is strictly mechanical and isn't caused by a hydraulic situation, just simple mechanical. So for clutch adjustment... 1) Set the pedal height with the master disconnected. 2) Adjust the master rod length such that the holes line up for the clevis pin and install the pin. 3) Adjust the slave rod to get engagement where it feels right. I'm no clutch expert, but after being inside a couple different master cylinders and understanding how they work, that's what I do.- 73 240 No spark

There should be power to the coil in both ON and START. During START, it is wired to bypass around the ballast resistor, and in RUN power is wired to go through the resistor.- 280z Auto to 5 Speed swap-- Clutch pedal height

Haha! Geometry!! It sounds like you have plenty of pedal height now!!- 280z Auto to 5 Speed swap-- Clutch pedal height

I agree. Moving the pivot ball towards the slave body should make it engage / disengage closer to the floor. So... A related question... What ID master and slave are you using? I think the masters are all 5/8, but I think slaves are available in 11/16 and 3/4. I think you should be running 11/16, but maybe you could change to 3/4 if you can't get satisfaction using just the adjustment on slave rod length.- 280z Auto to 5 Speed swap-- Clutch pedal height

Couple comments about the above... First comment is that the info you posted above (while all true) does not apply to what grannyknot is experiencing. He is experiencing a clutch engagement at too HIGH of a pedal position, not at too low of a pedal position. Granny is not running out of clutch throw, and in fact he's asking how he could effectively get LESS slave movement, not more. Other comment is I don't agree with the description of the use of the master adjusting rod. The rod is not supposed to adjust the pedal height... It's supposed to ACCOUNT for it. The up-stop bumper is supposed to set the pedal height and then the master rod length should be adjusted such that the holes in the clevis line up with the hole in the pedal. In other words... Set the pedal height first using the bumper, and then adjust the push rod length to account for the hole positions. Rod length should not set pedal height. Does that make sense?- 280z Auto to 5 Speed swap-- Clutch pedal height

Granny, Are you using an older "non-auto adjusting" slave with the threaded rod, or are you using the newer self adjusting style? Old style: New style:- 73 240 No spark

I believe I understand your first three tests and they produced the expected results. Nothing surprising there. I wish you would stop using "continuity" and give an "Ohms" reading instead, but I suspect the results would still be favorable. As for test #4, This part "While my test light was attached to pos battery. I got light when connected to neg side of points." makes sense to me, and is the desired result. But you kinda lost mo after that. I mean, I know what you mean that the points opened and closed (I assume yo (u were cranking the motor over with the starter), but I don't know what you mean by this part "got no power on other side of points". Where did you have the test light connected, and what did the light do? And for your test #5, repeat that test, but try holding the coil wire near (but not touching) the ENGINE instead of the frame. I believe it has been previously identified that you may not have proper grounding connection to the body (frame), but you do have a well grounded engine. The valve cover or intake manifold should be a suitable grounded location to use to repeat the test.- 280z Auto to 5 Speed swap-- Clutch pedal height

Glad to help. And I agree, it's probably a combination of all the parts involved. My 280 has a "down stop" rubber pad on the firewall, and I think that's a good idea. Hopefully you can figure out a relatively easy way to incorporate something like that.. I had one other complication aggravating my situation... I was working on an early 240, and I think my clutch pedal was bent a little. Rotated towards the brake pedal, if that makes any sense. The result of that twist was the foot pad portion of the pedal was closer to the floor than it should have been, and the hole for the clevis pin to the clutch push rod was too far from the floor. Both of those helped make my push rod "too short". I believe that is a known issue on early 240's, but I believe they stiffened the clutch pedal significantly by the time they got to the 280.- 280z Auto to 5 Speed swap-- Clutch pedal height

I just went through this exact same situation. Couple comments... First, there is supposed to be a rubber bumper stop to limit the "up" position of the clutch pedal. It appears to be missing on your assembly. That bumper is important so you aren't relying on the integrity of the little retainer clip that holds the actuator rod into the master cylinder to establish the up-stop. Second, I found the same as you that the down position was not even close to bottoming out the master cylinder, even when the pedal was all the way down. And that's good... You don't want to bottom out the master. Third, I had three masters here, and all three had different length rods. A Luk aftermarket replacement (same as what you have) was the longest. So for me, I adjusted the up-stop such that the clutch was the same height off the floor as the brake. It's less than 8.5 inches, but it matches my brake pedal. And between having the pedal at that height and having the push rod adjusted to it's maximum, mine lined up OK.- Does an LSD need better cooling?

That's pretty cool.- 73 240 No spark

Did you do that hotwire test yet? Once we know the results of the hotwire test and we are confident that everything from the ballast resistor, through the point, to the high tension coil wire is working correctly, we can focus our efforts upstream from there. Break the problem into small manageable pieces.- 73 240 No spark

Maybe I can explain the issue you are having with the diagram I posted. What you added to that diagram, is not correct. The diagram does NOT show the G/W wire going to coil +. It shows the G/W going to the tachometer. The OTHER side of the tach is a B/W wire, and that B/W wire goes to coil +.- 73 240 No spark

The G/W does not need to be connected at all if you hotwire it as I described. And about your other question... Some of the connections shown in the FSM diagram are made inside the harness. That diagram is a good functional description of how the system works, but it can be a little confusing if you are looking at the wires coming out of the harnesses. For example, the connection between the G/W and the tach is made in the harness and you don't have to tie that together manually. It's already done. When I get a chance, I'll try to whip up a sketch showing the connections in a different form. Still the same electrically, but drawn differently. In the meantime, just simplify stuff! Take all the wires off everything and hotwire the durn thing. Let's try to figure out if your distributor works!!! - Back Pressure Regulator Recommendations?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.