Everything posted by Captain Obvious

-

Headlight switch problem- 1978 280z

Sorry. My bad. Who am I to say something like that! Objection withdrawn!

-

Headlight switch problem- 1978 280z

Casting in brass??? Pardon my French, but you're out of your mind!! LOL!! Unless you're going to make a hundred thousand, just turn it on a lathe! I could make that part in less than ten hours. Nine-and-a-half to figure out how to make it right, and then thirty minutes to make a good one.

-

Headlight switch problem- 1978 280z

I think epoxy or something 3D printed would both be fine for proof of concept, but I don't think they would last. The thing that worries me about epoxy, would be low abrasion resistance and adhesion to the original remaining nub. And the thing that worries me about something 3D printed, is the very thin cross section where the nub captures the end of the spring. Brittle and prone to cracking? And regardless of what material is used, the original part looks like it melted. So the root failure here looks like it got too hot. That needs to be taken care of first. So since I'm in here... Other than friction resistance, is there any reason those nubs must be made out of plastic? Does it have to be non-conductive? Based on the switch pics above, it looks to me like the could be made out of metal? Brass for example?

-

Headlight switch problem- 1978 280z

Nylon 6/6 would be my first choice with Delrin being a close second. Both are easy to machine at that scale, but I think the Nylon is a little stiffer and stronger.

-

Strange intake noise?

Awesome! You guys beat me to it! Glad you figured it out and got the idle down to where it belongs. I think that had been suggested before too. Guess it never happened.

-

Strange intake noise?

chaseincats, This is correct. On the Z throttle bodies*, you have to be careful about how you block off the BCDD. Search around the forum a little and you'll find details. If you can't find them, let me know and I'll see if I can dig them up. * ZX is different.

-

Overheating Only Under Load

Yeah, you'll need to spend some time on that. Glad I helped you make it "better"? LOL! First thing I would do now is pull the wire off the new sender when the gauge is at max and see what happens. It SHOULD drop to low temp. If it doesn't, then there's a problem in the wiring or inside the gauge itself.

-

Cody's Goon

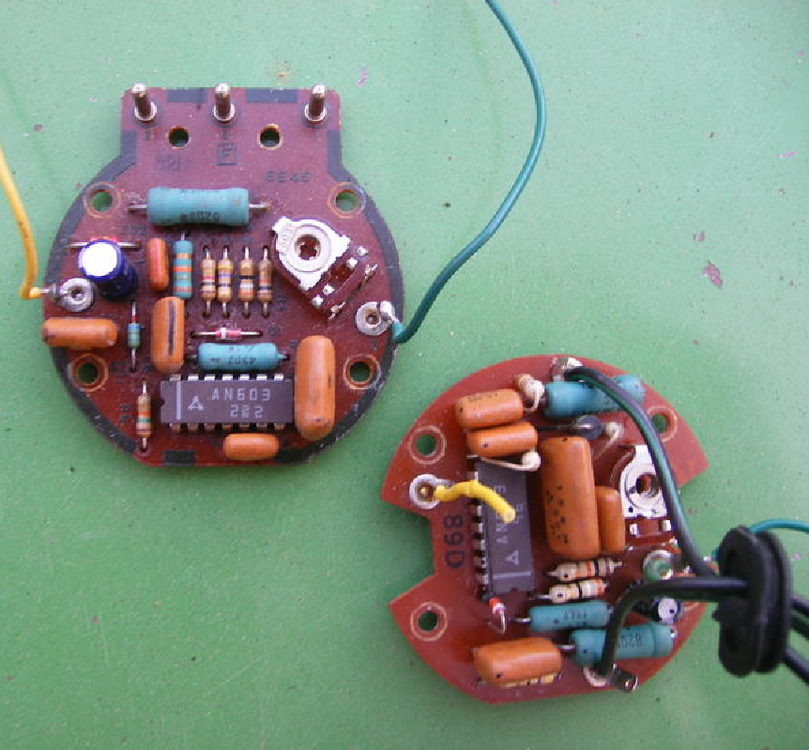

Yeah, that's the article in which I found the pics I was talking about. This is a 200SX on the left and 510 on the right. Oh, and youtube says the current sensing Z tachs don't have any IC's at all. Nothing integrated. Just discrete transistors.

-

Cody's Goon

Who knows... Maybe? Those sites always seem to have stock of any IC you are ever looking for. But do they really? I don't think I'd ever trust them enough to even try

-

Cody's Goon

Well this may all be for naught... I got a head start based on the pics from that Dime Quarterly thread I started looking for info on the IC chip - AN603. Based on the logo, it looks like a Matsushita (now part of Panasonic) part, but I couldn't dig up any info about it at all. So if I can't find anything about what's going on inside that chip, I might not be able to do much with it. I mean, I can certainly do a macro level reverse engineering and infer what's going on inside that chip, but that may be about it. And if it looks like there's something wrong inside the chip, I certainly won't be able to get a replacement except from another old donor part. I wonder if they used that same chip in the current sense Z tachs... Those are at least easier to find at this point. Anyway, regardless, I'll do what I can.

-

Cody's Goon

My thoughts? If the two tachs were in series and the one in the dash worked fine, then I think there is an internal problem with the 510 tach. I mean, there's a slight possibility it has something to do with the ballast resistor, but I suspect the gauge itself. I also think there is nothing to be gleaned from the seeming "proportionality" of the tach readings. I think that's a red herring. Steve, If you want to send me that tach, I'll open it up and do some reverse engineering on the guts? If nothing else, it'll be a great story about a tach that traveled all over the country. "510 Tach Tour!"

-

Overheating Only Under Load

I don't think you need any fancy burping tools for these cars. Just run it, let it cool, and top it off a couple times. That's all you should need to do. The 280's used a recovery tank, but I don't think the 260's did. They were a dump on the ground system. So there would normally always be some air in the system. Hopefully just one pocket corralled at the top of the radiator, but some air.

-

Overheating Only Under Load

I've seen plenty of intermittent temp gauge senders, but they're usually random and not repeatable like yours seems to be. First thing I would do is be double dog sure that the coolant system is full. And next is that I would replace the sender unit. It's easy and cheap, so I would just put a new one in there and see what happens.

- L20b Cody's Goon

-

Restoration of BringaTrailer 240z - HLS30-35883

Not much. Shift knob, front caliper hard lines, timing chain guide. I think that's it.

-

Restoration of BringaTrailer 240z - HLS30-35883

-

Restoration of BringaTrailer 240z - HLS30-35883

So in the rebuild kit they included new O-rings to seal the two halves of the caliper halves together? That's really nice, but a little weird since Nissan recommends never splitting them apart. Old fading brain cells tell me they didn't do that in distant past. Maybe I was just buying the wrong brand kit, but I don't remember getting those little O-rings as part of the rebuild kits.

-

‘77 280z signal fuse keeps blowing up

Really hard to troubleshoot intermittent electrical issues, especially from a distance, but here are my thoughts... First, I suspect the only reason the "fuel gauge" fuse is heating up is because of simple convection and conduction. My theory, which is mine, is that the heat from the A/C fuse is rising and heating up the fuel gauge fuse. And the second part of that theory is that there is really nothing wrong with the fuel gauge fuse system and the apparent heating of the fuel gauge fuse is a simple distraction. And as for why the A/C fuse is heating up so much... Does that fuse and fusible link heat up that much when you run the fan at it's highest speed WITHOUT the A/C being on? In other words, have you checked the temp of that fuse running the fan on HI while the HVAC system is in HEAT mode? It could be as simple as a tired old blower motor with dried out creaky bearings that doesn't want to spin fast anymore. Next, I'm having a hard time coming up with a link between your turn signal fuse popping and the A/C system. You have described a situation where you have the A/C on, and when you turn the signal on, the fuse blows. Have you ever had the situation where the turn signal is on and working correctly and then when you turn the A/C on, the fuse blows? And about the compressor kicking off when the fan is on the highest speed, we can talk about that later. It's probably dirty contacts inside the fan switch.

-

Door lock replacement 77 280z

Also important to note that the 77 and 78 locks are different than all the other previous years because the linkage actuator arms are different shape. Depending on the design of the lock cylinder, you might be able to move your original arms over to new locks, but they would need to have the same shape hole where they fit onto the back of the cylinder.

-

Space saver tire

I'm not sure I would want to stretch a 115 wide tire out onto a five inch wide rim. My thoughts on the matter while I was in the thick of it: "I didn't move the space saver tire over to the 280 original spare wheel because I was worried that the 280 spare wheel was too wide. The space saver tire was originally on a four inch wide rim and the original 280 spare wheel is five inches wide. I wasn't comfortable stretching that narrow tire out to a five inch wide rim. I think you could use a 4.5 inch wide rim, but since I was in there messing around anyway, I took the opportunity to make it as narrow as possible"

-

Car show Key Blank Code

Glad to help, and hope you find a cool looking blank for your car!

-

Car show Key Blank Code

Yeah, I found that wiki page as well and there's a lot of good info on there. But about your key blank and trying to use one of those titanium keys... Those TI keys are all for the double sided cut and there's no way they will fit your cylinder. Regardless which blank your lock uses, it's a single side cut and those TI blanks are for the newer double side cut. When they describe blanks, they look at the cross section profile from the part you hold in your fingers (they call it the "bow"). And if I modify your pic and flip it around so you are looking at that profile from the bow, it looks like this: And that still looks like an X1 / MZ12 or DA20 / D80K.to me.

-

Space saver tire

You know what they say about assumptions...

-

Car show Key Blank Code

If you already bought that lock from ZCD and have a pair of keys, then if you would take a pic of one of the keys head on, it could help in confirming the identification.

-

Space saver tire

MH77280Z, Good luck finding a 195/40/14. I took a quick look at tirerack for that size (or something else that might work), and came up with nothing. Good luck with the search. And note that the project I went through becomes easier if you are willing to deal with a space saver that will only fit on the rear. If you're willing to deal with that, then you can find spares right out of the junkyard that would work. I went the extra mile with swapping rims around, but if you don't want to do that, there are ways around it.