Everything posted by Captain Obvious

-

1971 HLS30-14938 "Lily" build

Well I hope the paint job turned out to your high standards!!

-

Carburetor Conundrum (260Z)

Well then it's time to pull that front carb off. And don't worry about how the front piston is going up farther than the rear. As 240Znomad suggested above, it's cause and effect... The effect is the piston raising. The CAUSE is something else. You fix the cause and the effect will go away. And don't worry about the damper oil right now either. What you are using is completely fine for now. In fact, at steady state idle, you don't really need any oil at all. Just doesn't matter. I'm thinking that something within the carb itself is keeping that front throttle butterfly from closing completely. Bent plate, plate installed backwards, plate misaligned badly, complicated choke linkage on side of carb not put together correctly... Something like that.

-

Carburetor Conundrum (260Z)

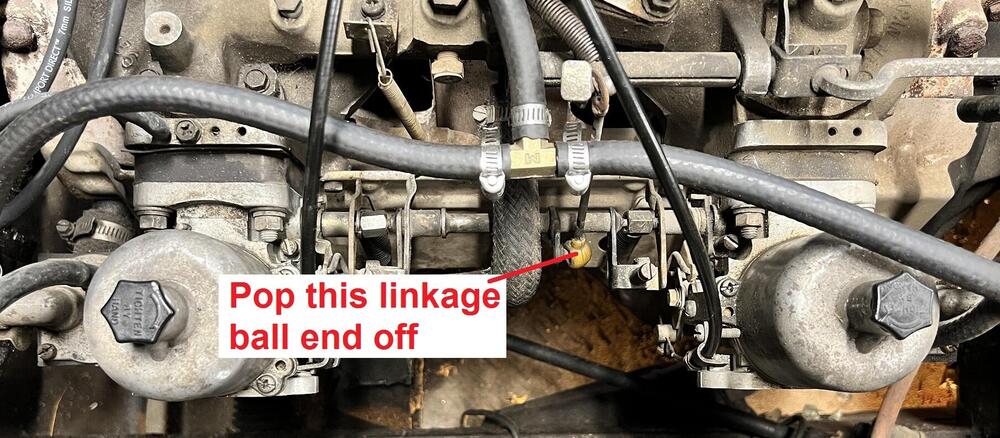

Something else to try... Start the engine, and while it's high idling, reach under the actuation tab on the front carb and manually pull it up gently to see what happens? In other words, "help" the return spring by adding some more force in the direction that would close the front carb. And just to be double dog sure, did you ever pop the plastic ball off the linkage to guarantee there isn't something in the linkage holding the front carb open? If you pop that ball off and pulling up on the linkage for the front carb has no effect, then I agree that it's time to pull that front carb off. It really wouldn't take much of a throttle plate opening to get you to a 2500 RPM idle with no load.

-

1971 HLS30-14938 "Lily" build

Woo Hoo!!! Man, I would have been puckering the entire time! And I hope you were wearing a really good mask!!

-

1983 280zx turbo engine

It turned out "just OK", for a number of reasons... First of all, evap-o-rust works better at warmer temperatures and I was doing this at the end of December in a wood stove heated shop. Because of that, the temperature of the block was cold. Like Pennsylvania December night cold. I had the wood stove cranking and had the air temperature in the shop up to a comfortable working temp, but that big chunk of cast iron was still pretty cold. Second, I would have liked to have left the evap-o-rust in there longer. Like overnight. But I was afraid that once the stove burned down, it would lose all effectiveness, and/or even freeze. So I had to limit the process to just a couple warm-ish hours. Third, we did two blocks and the first one we treated with phosphoric acid after the evap-o-rust and it turned out well, but boy did it stink. So I couldn't bring myself to do that a second time in a closed December shop, so the second block (mine) didn't get the phospho treatment. Bottom line.... I give mine a "5". I think if it were warmer and I left the evap-o-rust in there longer (24 hours) and then also treated it with phospho after, it would be an "8". Still not as good a hot tanking, but for a block that's not that bad to start with, I think it would suffice.

-

ZCON 2022 Roll Call

I am unfortunately not going to make this one either. It's just not in the cards.

-

1983 280zx turbo engine

And about your block rust: I've got the nipple on the side turned slightly downward to facilitate draining after the evap-o-rust had time to work. And you can see the piece of wire fashioned into a hook to hold the hose up until I'm ready to drain. Don't shake the shop!! Filled to the brim: I didn't take any pics of the water pump hole cover at the front, but it's bolted to the block to cover that hole that leads to the front cover. Doesn't have to be fancy. Just something to keep the liquid from leaking out that hole.

-

1983 280zx turbo engine

So I hope you actually counted the number of freeze plugs you needed and didn't simply rely on my memory. Because... Last time we were talking about those plugs in this thread: https://www.classiczcars.com/forums/topic/67591-p90a-head-f54-block-correct-head-gasket/ I had the numbers wrong... I have since found my bags of plugs and took a fresh look at the F54 block, and here are the correct numbers: The F54 block has a total of eleven freeze plugs: Nine 35 mm One 40 mm One 50 mm I bought (a quantity of two) Sealed Power part number 381-8027 sets off rockauto Jan 2020 Each set contains 1-50mm, 1-40mm & 7-35mm plugs and because of that, I had to buy two sets to get enough of the 35mm plugs.

-

Carburetor Conundrum (260Z)

Haha!! I've heard is said that it's one of my many endearing flaws.

-

Electrical Engineering Geek out. Coolest Switch Ever

Wow! How did I get to be this many years old and have never ever seen anything like that before. Ever.

-

Carburetor Conundrum (260Z)

Well then you haven't read many of the things I've written. Haha!! But regardless, it's clearly an experience issue here, not ability. You'll get it!

-

Carburetor Conundrum (260Z)

So getting back to the current issue at hand of your idle being high even with the adjustment screws being turned out. Another remnant of your previous carb conversion is the (vertical) linkage rod that pushes down on the center linkage... That rod used on your original carbs (flat tops) is a different length than the rod used for your current round tops. Most people replace the original longer rod with a correct one, but it appears your previous owner modified your original rod instead. Looks like he cut one end off and attached a loop to the top. "Welded" maybe? In any event, it looks like from your pics that linkage is already slack, but just to make double dog sure, you can pop the plastic ball off the linkage at the bottom. That way the center linkage between the two carbs should be guaranteed to be loose and not affected by anything else upstream. Here's a pic of what I'm talking about. You should be able to use a small screwdriver and pop the plastic female end off the male ball:

-

Carburetor Conundrum (260Z)

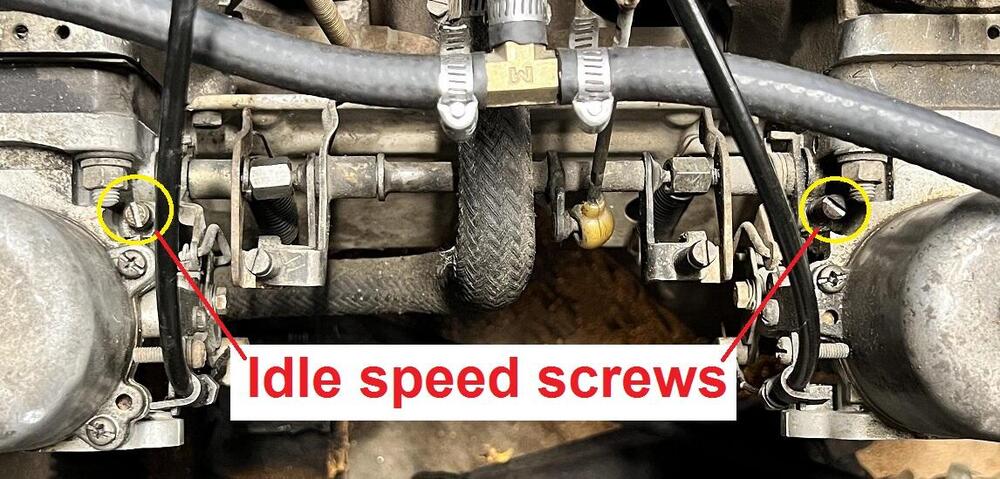

Haha!! Figured. And don't feel bad about it. If you have no experience with those carbs, you just have no experience. So when they said to loosen the linkage, the intent is "Make sure the center linkage is not actuating either of the two carburetors." Or put another way... "Loosen enough of the adjustment screws to make sure the linkage is not holding the carbs open at all." So in the interest of teaching a man to fish... You currently have four adjustment screws. The original system had five, but because of the previous carb conversion that has been done to the car, one of the five original screws does not exist. The one that does not exist is the "fast idle adjustment". Don't get worked up about the non-existence of that screw as I believe it's only function is to temporarily raise the engine speed while checking carb sync. Once the carbs are synced, you loosen that screw and it does nothing until the next time you want to check the carbs. So the remaining four screws... Two of them are idle speed screws (labeled in my pic above) and then there are two others. The front screw of the two others - You will notice that since you removed that front top spring, the piece that screw is attached to is loose and flopping around. The reason for that is it originally connected to a piece of emissions equipment which has been removed from your car. That screw and the floppy linkage piece it threads into now do nothing. Forget about it. Many people zip-tie it to the linkage between the two carbs so it isn't in there flopping around, but even that is not necessary. Then the fourth screw - The one on the center linkage towards the rear. That one is your sync screw. AFTER you get your car idling properly, you use that screw (in conjunction with the fast idle screw) to make sure the carbs are sycned ABOVE idle. KInda hard to describe some of this with just words. If you want, I can add some more annotations to the pics.

-

Carburetor Conundrum (260Z)

Yeah, I was thinking the same thing about the butterflys. It sounds like the front one is not closing all the way. Either due to an external linkage issue, or from an internal issue like the butterfly plate has been removed in the past and was not reinstalled correctly. And I'm not sure what manual you were looking at that recommended loosening those nuts, but it's neither necessary, nor a good idea. I'd get those tightened back up. I'm thinking it was a misinterpretation of the procedures. Something like maybe you read "loosen the linkage between the two carbs" and your interpretation was to loosen those two nuts? If that's the case, then it was a misinterpretation, and you should get those tightened back up.

-

Frankenstien Engine for Junk Car race

I've measured a couple stock heads and the original thickness of the N47, the P79, and the P90 is 108 mm (4.255 in). You can use that 108 mm measurement to determine if a head has been cut previously or not. I haven't measured the other head varieties (because I haven't had them pass through my hands) so I cannot tell you what the others are, but I suspect they are all the same.

-

1973 Rebuild

Yeah, I figured. It really sounds like a cool mod, and it's been forefront in my mind recently because my clutch is squeaky and notchy. I'm sure I need some attention down there.

-

1973 Rebuild

I assume if you had pics, you would have posted them?

-

Carburetor Conundrum (260Z)

And just to make sure we are talking about the same screws... You're saying you loosened up four screws (including these) a whole bunch and you are still idling at 2500 RPM?

-

Carburetor Conundrum (260Z)

-

Carburetor Conundrum (260Z)

Yup. That's the one I referred to as "the top front return spring kludge". Much easier to identify with your annotation on the pic. The way is right now, it's pulling the throttle ON instead of pulling the linkage off.

-

Carburetor Conundrum (260Z)

Seeing your pics, you do have the return springs on the carbs (hooked down onto the heat shield), so that's not it. With a quick look, I do see some stuff that isn't right though... The long hex nuts that go onto the throttle butterfly shafts are loose on both ends. The front carb is loose, and the rear carb is missing a lock washer and is loose. The top front return spring kludge appears to be pulling the center linkage in the direction that would increase throttle position. If it's fighting against the front carb return spring (and winning), that will open the front carb and raise the RPM. You shouldn't need that spring at all. I'm not currently in position to annotate pics, but I'll do that later tonight unless someone beats me to it. And also... Yes, the cables are choke cables. When pulled, they also open the butterflies some to raise the idle speed. So it would be important to make sure the cables aren't pulling the carbs open.

-

1973 Rebuild

I have vague recollection of someone here putting roller bearings into their clutch pedal to get an uber smooth fantastic pedal feel. I'm gonna test old brain cells and tag @zKars maybe, for possible pics of this process?

-

1983 280zx turbo engine

Your plug installer tool looks great. I spent way too much time making a custom application device on the lathe. Don't have any pics, but when I use it, I'll snap some. Yours not only took a lot less time to create than mine, but it's also adjustable which mine is not. Forest through the trees....

-

1983 280zx turbo engine

Haha! If you're anywhere near as good at counting the beans as you are with the stuff that you really enjoy, then you must be pretty good at all of it! I'm not worried at about you opening up your first motor.

-

1971 HLS30-14938 "Lily" build

I'm pretty sure you know this already. but one might point out that the order of operations here is extremely important.