Everything posted by Captain Obvious

-

280z master fuse list?

I've not seen a master list like that. And I agree... I think that would be a valuable tool. Kinda surprised someone hasn't put one of those together. Of course, it would be year specific.

-

What is your most valuable 'made-it-myself' tool?

Haha!!! Yessir!! I think everyone can agree that a well formed nubbie is a thing of beauty!

-

What is your most valuable 'made-it-myself' tool?

Yeah. the 72 carbs, even though they are mostly like the previous years, they do have their weird idiosyncrasies. I find it neat to see some of the changes put into play on the 72 3-screw carbs that were clearly stepping stones to the flat tops they used the next year.

-

What is your most valuable 'made-it-myself' tool?

Oh, and all that about dome alignment... Here's my dome / nozzle sleeve alignment tool. Centerless ground precision stock. Sub-thousandth tolerance. Take out the suction piston and put this in it's place: So how do you use it on the 3-screw round tops? Well, if you still have alignment nubbies, then you don't need to align anything. It should already be aligned. But if one or both of your alignment nubbies are broken off... Insert the alignment tool into the carb body and put the dome on: And then while the dome is held in "perfect" alignment, you cast the alignment nubbies in place: Fill up the hole and then wipe off any excess: Then once the nubbies cure, pop the dome off, and presto... New nubbies! : The eagle eye might notice that carb is a flat top, but the 3-screws used the exact same alignment technique.

-

What is your most valuable 'made-it-myself' tool?

I respectfully disagree. That needle/nozzle alignment method will not work on the odd bird 72 3-screw round tops. The nozzle sleeve is not adjustable on the 3 screw round tops. On those 72 carbs, the nozzle sleeve is pressed into the underside of the carb body and does not come out. Once it is pressed into place, it's fixed. No adjustment: So since the nozzle sleeve is hard fixed, they do the needle alignment using the dome up top instead. The three hold down screw holes are intentionally sloppy allowing the dome to be positioned in the correct location. With that in mind, the needle alignment on the 3-screw round tops is set at the factory using the cone shaped alignment nubbies. Cast in place once the domes were aligned with the nozzle position. The alignment was set at the factory. Once and done and (assuming the original nubbies have not been broken off) nonadjustable after they leave the factory. I assume they took that power out of the owner's and dealers hands because they felt they weren't doing it right. Here's a 3-screw nubbie:

-

280z mode door foam replace?

Glad to help. Sorry I didn't have better news or a simpler way to fix it. And since I'm already the bringer of bad news... The normal temperature control lever should also be able to block off the flow to the heater core. If you've got it slid all the way to COLD, then the heater core should be cut-off. Yes, when you switch to A/C, the other valve should do that automatically, but you should still be able to do it manually with the lever actuated valve. So if you've already got the temperature lever slammed all the way to COLD and you're still getting a hot air through the heater core, then you've actually got three problems: Your mode door foam is leaky. Your vacuum-cokk valve is leaky. Your temperature control valve is leaky. All pretty much normal for these cars.

-

Fuel pouring out the front of the carbs

And by the way, I think we're all saying the same thing here... Carbs need fuel in the bowl in order to operate correctly. And that fuel won't get into the bowl by magic. It takes pressure. It might not take much... In fact, in many circumstances, simple gravity is enough. But there must be something that pushes fuel into the bowl. But for a car like the Z with a tank located below the level of the carbs, you need a pump. And a pump needs specs. So Datsun provided some specs in order to qualify and test the pump(s) used in the cars. "Should be able to provide this volume at this pressure and no higher than this." It can be somewhat arbitrary as long as there's enough fuel provided at extended full throttle, but not so much as to force the float valve open at idle when you don't need nearly as much fuel.

-

Fuel pouring out the front of the carbs

Cracking pressure is a term most associated with check valves. They are be held closed by something (usually a spring), and there is a certain amount of pressure required to overcome the combination of stiction and the force of the spring in order to force fluid through the valve. And even though not necessarily considered a check valve, the construction of the needle valve is identical to a check valve. The only difference is that the compression of the spring (and hence the force supplied) is variable because of the moving float. Here's some good pics and description of cracking pressure: https://www.hydraulicspneumatics.com/technologies/hydraulic-valves/article/21884995/engineering-essentials-pressurecontrol-valves And from that page, here's a neat sketch showing why (even though it's not a "check valve", the concepts cannot be ignored even for the float valve. If you replace the adjustment screw with the float tang, here's the carb float valve:

-

280z mode door foam replace?

Yeah, I took a look at the vacuum diagrams and it's not a vacuum leak. The no-vacuum "default" position of the water valve is closed and the default position of the mode door is "dash vents". In other words... If there is no vacuum applied to anything, you get recirculated air, unheated, out the dash vents. If you add evaporating refrigerant, you get cold recirc air out the dash. So back to the original issue... It sounds like your water valve is passing water when it shouldn't be and your mode door isn't a perfect seal. No you can't refoam the mode door in-situ, and working on that water valve up under the dash is "possible", but very uncomfortable without pulling the dash. You could install a manual water valve up in the engine compartment. Being in Dallas, I gotta believe you could use a manual valve to completely cut off all the water to the heater core for most months of the year, and you wouldn't miss it. Wouldn't "fix" either issue, but it could be a relatively simple workaround for the majority of each year.

-

280z mode door foam replace?

I think if your hands are small and you are a limber gymnast (who have small hands anyway, so I guess the crack about the hands is redundant) I think you can replace that valve without pulling the dash. It's behind the blower motor tucked up where the heater core hoses are. It's a bundle of snakes down there. However, first thing I would look into is... Is that valve getting it's signal to close? In other words, just because that valve is passing coolant even when it's not supposed to, is the problem actually in the valve, or is the problem somewhere else (like a dry rotted vacuum line under the dash)?

-

Fuel pouring out the front of the carbs

It's not the weeds at all. You need pressure. Enough to overcome the cracking pressure when the valves are closed, and enough to overcome the orifice restriction that is the needle valve. Tables and tables and charts and formulas for the pressure drop across an orifice. Reynolds number, temperature, flow rate, viscosity..... Depends on a whole bunch of factors, but the bottom line is you need enough pressure to push the fuel in under all conditions, but not so much as to force the valves open when you don't want them to be open. It's a little mini-control loop with pressure being the energy that makes it all work. If it worked without pressure, it would be a perpetual motion machine.

-

Fuel pouring out the front of the carbs

Carbs DO rely on pressure. You need to overcome the cracking pressure of the float valves. It might not be a lot of pressure required, but it's non-zero, and the system will not work without it. Too much is a problem, But no pressure is a problem as well.

-

280z mode door foam replace?

First, to answer the question... No. It is not doable without taking the dash out. If you didn't have A/C, you miiiiight be able to replace the foam on the visible side of the door, but even so, that's not the side that you're having trouble with. You're looking to deal with the side you CAN'T see. However... When your system is switched to A/C, all coolant to the heater core supposed to be shut off. Automatically. So if you're getting hot air out of the heat holes, the valve that is supposed to cut the hot coolant is leaking. If the air coming out is "ambient" (unheated and uncooled), then maybe it's just the foam on the mode door. But if it's hot, then you have more than one issue.

-

Fuel pouring out the front of the carbs

According to the 74 FSM (page EF-9), the electric fuel pump should deliver 1400 cc (85 cu in) in one minute or less. And also on the same page, it lists the pressure spec at 4.6 psi. No idea if that's what they actually did, but that's the spec.

-

Fuel pouring out the front of the carbs

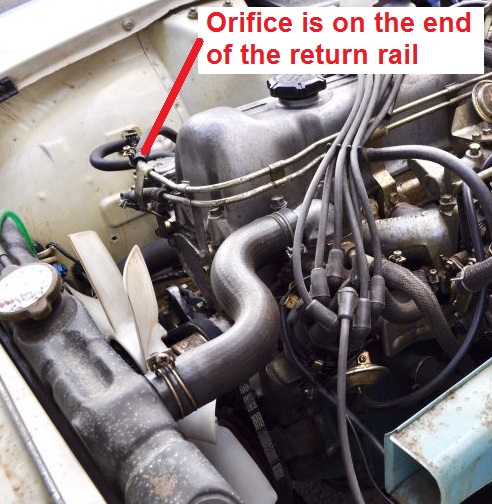

Yup! There it is! Thanks for the pics! So that little hole partially blocking the return line of the rail is what provides the fuel pressure to the carbs. If that return line wasn't necked down like that, the pressure in the rail would be pretty much zero and the carbs wouldn't get any fuel. That orifice provides the restriction which generates the pressure in the rail.

-

Fuel pouring out the front of the carbs

Yes, there is an "on-purpose" restriction on the end of the return side of the fuel rail right where it transitions to the rubber hose (over by the fuel pump). It's a swaged down tip brazed onto the end of the return leg. I've got all kinds of pics of all kinds of carb stuff, and I can't find a single detailed pic of that orifice restrictor. So, all I've got is this: I'll take a look to see if I have any 240/260 fuel rail stuff around here. Not sure I do, but I'll look.

-

Tuning With An Air/Fuel Gauge

I'll see what I have for ECUs here. I don't know if I can tell anything from the label, but I'll look. So here's to hoping the lean boot thing just doesn't come back, but in reality what will probably happen is that it'll occur when you're dressed nice and don't want to go popping the hood and pulling wires off and all that. Haha!

-

Brake booster push rod adjustment

Good. Glad that worked out. It's the little things!

-

Brake booster push rod adjustment

It's not supposed to turn easy. They designed it so the threads are intentionally tight. They don't want that thing screwing in over time as you use the brakes. But it shouldn't be impossible to turn either.

-

Tuning With An Air/Fuel Gauge

Understood about the timing. Maybe you'll get lucky and it will never happen again. (Suuuuuuure). And I'm not proposing any theories yet... I'm just trying to come up with something, anything. to maybe point in the right direction. I'm thinking that if you do the "START with engine already running" a couple times and nothing changes, then maybe it REQUIRES the engine to actually come to a stop to reboot. Injectors need to stop injecting, coil needs to stop coiling... all that. On the other hand, if you do that test and the lean condition DOES go away, then there might be some info to be gleaned from the fact that the engine does not need to a complete stop in order to make the lean boot go away. Vibrations don't need to stop, starter does not need to suck a big hit of current from the battery. Alternator doesn't need to bootstrap. That kind of stuff. Just fishing at this point.

-

Tuning With An Air/Fuel Gauge

The engine should already be running. Let me try again to explain. Next time the car starts and you notice this lean-boot condition. Let it run, but while it's running, pop the hood, get out of the car, and disconnect the small black/yellow wire from the starter solenoid. Then get back in the car (all with the engine still running), and turn the key to START. The engine will already be running (because you never shut it off), but the starter will not engage since you have that wire pulled off the starter. Flick the key between ON and START and see if it drops out of lean boot and into regular running mode. Does that make sense? You can drive like that with the starter wire disconnected, but just remember that when you shut the car off, you'll need to reconnect the starter wire to get the car to start again.

-

Tuning With An Air/Fuel Gauge

OK. I had a couple goofy ideas. First thing... The original EFI systems were fully analog and there were no computers used. But then some time along the way (early eighties), they started putting embedded microprocessors in the ECU's and using software to do the control instead of analog voodoo. Why does that matter to me? Because if it's got a microprocessor doing the control, then this kind of latching behavior would be easier to explain. So I know your Z is a 78, which should be fully analog, but do you know for sure? Have you ever had the cover off the ECU? Got any pics? Second thing... There's a circuit inside the ECU that is supposed to provide a little extra richness boost immediately after starting the engine, and that extra richness gradually tapers off (30 seconds or so) after the key is released. Maybe that section of the circuit is not functioning correctly, or maybe that circuit is being fooled into thinking that the key is always in the START position. When you turn the key to START, a couple things are supposed to happen: The starter engages (duh) The floor temp lamp light is supposed to light up (lamp test for CA models only) The cold start injector gets the opportunity to spray (depends on how warm the thermotime switch is) The ECU get's the signal to begin the START enrichment boost So here's what I'm thinking... Next time the car lean boots, try this: 1) WHILE THE ENGINE IS RUNNING, pop the hood and disconnect the small Black/Yellow wire going to the starter. 2) Turn the key to START again with the engine still running in lean-boot. Don't worry... With the B/Y wire disconnected, the starter will not engage because you have removed it's signal to engage. But all the other "harmless" functions will be activated. The floor lamp should light up, the cold start injector should give a squirt (if it's cold enough), and the ECU should get a fresh "START" signal. The idea is that you can flick the key between ON and START a couple times to see what happens to your mixture readings. See if your lean boot symptom goes away without having to shut the car off completely? Maybe it'll go away with just a flick of the START signal. Like I said, I'm just throwing some stuff out there!

-

Tuning With An Air/Fuel Gauge

Gotcha. I'll think about it, and the meantime, let's hope someone else knows exactly what's going on!

-

Fuel pouring out the front of the carbs

Yeah, it unfortunately sounds like the bowl level is going too high for some reason. Either the fuel pump is forcing the valve open, or the setting was always ballpark and never precise. The wet set method is a bit of a pain, but it's the only way to be sure. If you want to confirm the theory, you can unscrew the air vent nipple on the top of the float bowls and see what happens. Nothing is supposed to happen, but I suspect you're going to have fuel come pushing out of those vents. And the only way that happens is if the bowl level is too high.

-

Tuning With An Air/Fuel Gauge

This is a 78, right? With mostly stock EFI system?