Everything posted by Captain Obvious

-

Putting in a replacement L-28

On final approach now!! Whatever you do... Don't connect the battery until you're sure you've got everything else correct! including the fuel injection power leads. They're both red, so that's an easy way to get screwed up. Ohm them out to the ECU connector if there's any doubt.

-

Bleeding rear brakes

Perfect. That means we're doing it right. So to your final question about vacuum bleeding vs. pressure bleeding... Again, I'm no expert on the topic, but I would suggest pressure bleeding over vacuum bleeding for a couple reasons. First, I believe you can generate a whooooole lot higher pressure differential with the master cylinder. I didn't research it, but I would expect that when you push the pedal hard, you can generate hundred(s?) of PSI in the lines. But if you're drawing a vacuum, the max vacuum you can achieve is less than one atmosphere (less than 15 psi). So for pressure bleeding, your pushing fluid through the lines with hundred(s) or PSI, but with vacuum bleeding, your pulling fluid through the lines with less than 15. Seems you would be much more likely to generate that bubble-free "slug" of fast moving fluid if you're using a higher pressure differential. Second, the seals used in the system are designed to keep pressure IN, not keep pressure OUT. All the seals are angled in such a way as to designate which side is the high pressure side and which is the low pressure side. The seals are all designed to expand outward and provide more sealing force when the pressure behind them increases. I've run the exact same scenario that Zed Head did (bleeding a clutch slave cylinder) and when I released the slave plunger, it pulled air past the seal back into the fluid side. So either he got lucky, or I got unlucky, but what worked for him did not work for me. I had to pressure bleed because the vacuum generated when I released the slave plunger allowed air in faster than it would pull fresh fluid from the clutch master.

-

Countersinking Weber DCOE throttle shafts

Well I never spend huge amounts of time working on something, that in the end, is really unnecessary. Ever.

-

Bleeding rear brakes

Haha!!! I'll get right on that! Or not.

-

Bleeding rear brakes

I don't think it would be much different. That's what I meant about the fluid flowing fast coming out of the master cylinder. The reason it would flow so quickly through the lines is because of the small volume that actually exists inside the brake lines. Grannyknot's put it well above, but let's put some numbers on it... If the ID of the lines is .118 inches (3mm), then the cross sectional area of said tube is .011 square inches. That means in a ten foot run of brake line, there is only about 1.3 cubic inches of brake fluid. I'm thinking that even if there is a bubble in the middle somewhere, it's just going to get pushed out ahead of the next slug of liquid when you're bleeding the system.

-

Countersinking Weber DCOE throttle shafts

Haha! What about the "None of us need more work to do." part?

-

Bleeding rear brakes

Good pic. As for the fluid dynamics... I had one class in fluid flow and thermodynamics*. I consider it the worst class I took in my entire educational career, and I got zero out of it. At the time I had absolutely no interest and (as an EE) could see absolutely no practical value to me. So it bounced off my brain and I managed to scrape through with a "C" using short term memory and a stiff grading curve (because pretty much everyone tanked the tests). But now... Now that I've got a whole bunch of automotive related applications, I bet I would get a whole lot more out of it. *Probably told this story before, but I'm gonna do it again anyway.

-

Bleeding rear brakes

Richard McDonel, I believe your asking "Why wouldn't air bubbles get trapped inside the hard line or rubber lines since they are higher than the bleeder screw on the wheel cylinder?" I'm no fluid flow expert, but I'm thinking the fluid coming out of the master cylinder flows so fast that it pushes virtually a full slug of brake fluid liquid along inside the small diameter lines. The slug of fluid doesn't really want to separate and it just pushes all the air out ahead of "the wave", and even when you lift the pedal to get ready for another push, even if a bubble were to flow out of the wheel cylinder, it won't happen fast. You'll blow that bubble out on the next push. Capillary action and vacuum lock and all that... That's my non expert theory anyway.

-

Countersinking Weber DCOE throttle shafts

I agree with Patcon's assessment above, but since I love a list... Here are my answers to your questions. 1. How much difference? Immeasurably small. 2. How hard would it be? Pain in the butt to do it right. 3. What size? Doesn't matter. Glad we could talk you out of it!

-

Anyone know a place to restore an original 240z Hitachi Regulator?

I think ZH nailed it about drilling out the rivets. If you're absolutely insistent on running a stock regulator (guts included), then I think that would be your only option. There's no way the electronics would do well in the plating process and you would have to remove them first. I guess maybe, just maybe... There might be a company who specializes in this sort of thing where they would pot the sensitive bits in some sort of compound to prevent the plating fluids from making contact where you don't want them. But I think it would be easier to drill the rivets out and desolder the guts to remove them. Not "easy" at all, but probably "easier". If it was a matter of life-n-death, I could also picture some sort of sealed dam walls being glued/sealed to the base to build a wall around the guts. Some creative walling and partial submersion to just the right depth might work too. But there's no way I would want to hand a part like that to someone else and ask them to plate it. It would have to be you doing it yourself with a home kit.

-

Putting in a replacement L-28

Wow that looks fantastic!! Was the installation process nerve wracking, or did it all go smooth?

-

Z's on BAT and other places collection

I suspect the explanation is nothing too nefarious... I'm thinking the photographer just screwed up and forgot to take a straight on left side pic and then tried to hide his mistake by mirroring the right side and photoshopping the decal. They shouldn't have done that, but I'm guessing it was something like that. It's not like the left side of the car is all caved in or anything. There are other shots from the left that show it's OK. Except for that exhaust. LOL.

-

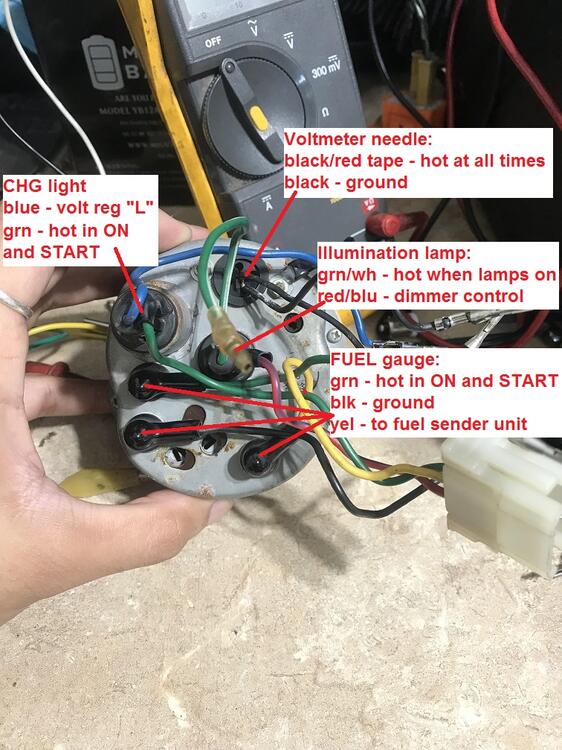

Waving Voltmeter

Oh, and while you have the gauge on the bench... The two voltmeter connections (Black and black with red tape) should be completely isolated from everything else about the gauge, including the metal housing. Take a resistance reading between those two wires and gauge housing metal and it should show no connection. And the other ground (the one for the fuel gauge) should be the opposite and should be tied hard to the gauge metal housing. Check that one too. I'm just still a little bugged by your waving voltmeter test that started this thread. I still think the problem was either simply just the wrong wires used or a source impedance issue with your motorcycle battery getting pulled down by the additional load of the fuel gauge, but I'm just looking into other possibilities while you're in there.

-

Waving Voltmeter

OK, I found a spare volt/fuel gauge here and it's the same as the one in your pic, so I think we have a solid point of reference. I added descriptions to the wires in your pic trying to show the functions. Important to note that the wire colors here ARE THE WIRE COLORS RIGHT AT THE BACK OF THE GAUGE. The reason that's important to note is that Datsun SOMETIMES CHANGED THE WIRE COLORS AT THE DASH CONNECTORS, and I believe the volt/fuel gauge is one of those situations. So be careful when referencing wire colors on the wiring diagrams since they sometimes changed colors on the gauge side of the connectors. In other words, the colors on the diagrams are the colors that exist ON THE HARNESS SIDE, and not always on the gauge side. But all that said... Here's what the wires do right at the back of the gauge: Most of the connections are unique and should be relatively easy to identify on the dash side (assuming things aren't TOO hacked up), but there are two connections that are not. There are a) two ground connections, and there are b) two "hot in ON and START" connections. a) The two ground connections just go to ground and there's no real requirement for them to be kept separate. If you wanted to for some reason, you could just connect those two to the exact same ground location. b) The two "hot in ON and START" connections originally went to two different fuses in the block, but if you get really stuck and just can't deal with it anymore, then it probably doesn't matter much which fuse get's which function. But if you really want to figure out the real-real correct fuses, we can work through that too. So with the different years and different PO's in there, I think it's going to have to be up to you to find the correct connections on the dash side, but that's what they should be connected to. Is that enough excruciating detail? Hope that helps!

-

Waving Voltmeter

Cool. I think I have a loose volt/fuel gauge around here to snap some pics. Just to make sure what you have there is the same as what I have here. I think that with the mix-match of years/harnesses/parts, etc, we need a solid point of reference. I'll see what I can find.

-

Waving Voltmeter

Well I'm not really sure what would be the best way to proceed here... I've got two proposed ways to go forward: 1) We can go over the exact three wires would be needed (in excruciating detail) to confirm or deny your waving voltmeter phenomenon on the bench. 2) We could skip the above step and I could document (again in excruciating detail) what each of the wires on the back of the gauge SHOULD connect to and leave it to you to find the corresponding wires on your car (because your dash harness is non-stock and I don't have reliable documentation for what's where. Those are my thoughts. What do you think would be best?

-

Baseline settings for triple OERs

My non-expert thoughts on the matter? Most of the fuel injection systems have a long-ish intake tract and some sort of air flow meter along the way towards the air cleaner. Both of those restrict the air flow. Might not be much restriction, but it's more restriction than a short stub of a carb throat running wide open. For example... When they went to the fuel injection in the 280Z, each cylinder got a whole lot less throttle plate cross sectional area to the air cleaner than they did when they were running carbs. In addition, the fuel injection system has that AFM flapper thingie which adds some restriction. So while it's absolutely POSSIBLE to design and install a FI system that provides no additional intake restriction over a typical set of carbs, I think it's cheaper for the manufacturer to use something that shares components like throttle body and air flow meters. I don't think the manufacturers went to fuel injection because of performance. I think it was because of driveability, fuel economy, and emissions. So I'm no expert in the field, but my take is that for most stock automobiles these days, if you're willing to forgo wide temperature range drivability, fuel economy, and emissions... I think you can get better straight up raw performance from a carb or a bunch of carbs. Maybe a set of ITB's and a huge MAF that doesn't provide only negligible restriction could be the same as carbs?

-

Leaking from spark plug sockets

Haha!! I think you've been lying in wait just looking for the opportunity to use that!

-

Waving Voltmeter

And about your dash gauge color... I changed my Z over to white and never looked back. I had amber in my late eighties Pontiac Fiero and it was cool. For about a week.

-

Waving Voltmeter

So it sounds like this is a non-stock application where you're putting a 280 gauge into a 260? Do you know what year is the gauge? And by the way, forget that stuff I said earlier about the grounds for the voltmeter and the fuel gauge being tied together inside the gauge... They're not. I was not reading the FSM diagrams correctly. The two black wires at the top of the gauge (one solid black and the other is black but has a red wrap of tape on it). Those two are for the voltmeter. I assume the one with the red tape on it is positive and the other is negative. Those two come out of the back of the gauge at 12:00 ish when looking at the back. And then the voltmeter ground is the other black wire that comes out of the back of the gauge at 8:00-ish Those are the three wires you're working with?

-

Waving Voltmeter

Forget all that stuff I wrote here. It's wrong. Oh, and by the way... The ground side of the voltmeter and the ground side for the fuel gauge are already connected inside the gauge assembly. So when you say "you're connecting the fuel gauge ground"... I'm not really sure what you mean by that. In other words, there is no fuel gauge ground accessible outside of the assembly. There is the fuel lever sending unit connection, but no ground. So if I had to shoot from the hip here, I would guess you're connecting the wrong wires somehow.

-

Waving Voltmeter

That wiggle is caused by the temperature/voltage compensation circuit built into the fuel gauge portion of the meter. But that said... the wiggle should not be happening, so let's explore a little. It looks like a source impedance issue where the amount of current you're pulling from your source is dragging the supply voltage down. The question is "But why?" How many wires are you connecting on the gauge? Two for the voltmeter, and a third when you bring the fuel gauge into the picture?

-

MSD box

@Mike

-

Stop Light Sensor override

@Mike

-

Time to Speculate : Coil Spring Breakage

Maybe they were designed like that. Variable rate progressives. The lower coils bind on big bumps. You know... Like when you let it down off the jack.