Everything posted by Captain Obvious

-

Best Head

Jon, What's something like that worth? I've got a P90 here collecting dust that someone has done that kind of work to. Not quite as extensive, but similar.

-

Any Mechanics in Pittsburgh?

Have you done any of the testing from the EFI handbook (commonly called the EFI bible)? https://atlanticz.ca/zclub/techtips/efisystem/280zfuelinjectionbook.pdf Most of the testing there is done at the big ECU connector. I would be interested in hearing what your coolant temp sensor resistances are both cold and hot. And about pulling off a plug wire to check for a misfire... Not good for the ignition system. A better way is to pull off the injector connectors one at a time and see if the idle changes. Lastly, your compression numbers are definitely low. Did you block the throttle wide open while you cranked the engine for the compression test?

-

Any Mechanics in Pittsburgh?

Pooky, I'm not sure I understand the problem(s) you're having... How bad is the problem? Is the car drivable? What's the worst of the problems? Maybe we can start there and knock them out one at a time? Also, @mgood is and active member and he's in the Pittsburgh area. Maybe he has some input for local help?

-

Tuning With An Air/Fuel Gauge

Well regardless if they flow the same, that's pretty annoying. The color may not matter, but on my engine, I would want everything to at least match. So I have no idea if the size of the opening on the bottom is the only thing that would affect the flow rate. I kinda doubt it. I suspect there are other internal geometry areas which could affect the flow rate too. In other words... Just because the hole in the bottom is the same, I wouldn't assume they flow the same. You could test them to compare the rates:

-

Engine Timing Cover

Sorry. One more thought about the timing chain and the tensioner sticking out... So the 240 slack side guide (the curved side) has a slotted hole at the top and two holes at the bottom. You have your guide with the bottom bolt going through the inboard of the two holes. I know this because I can see part of the outboard hole poking out from under the bolt head. But a pic here from @siteunseen, he has his lower bolt through the outboard hole. This effectively pushes the guide further in and tightens the chain: While putting in a whole new timing set is rarely a bad idea... What are the chances that the majority of the slack in your chain is due to an improperly installed slack side guide? I'm more of a 280 guy and the 280 guide is a little different. Just one hole that the bottom so no decision making on which hole to use.

-

Tuning With An Air/Fuel Gauge

Well color of the plastic doesn't necessarily indicate the flow rate of the injector, but to answer the intent of the question... Yes, if the new injectors flow more than the old ones, then you'll likely have to retune the system. But hopefully now that you have the other bugs and issues worked out, it should be a much easier process.

-

Engine Timing Cover

Good. I was thinking that some of the timing kits do not come with the guides, and I would certainly take the opportunity to replace the guides if you're doing everything else. Man that tensioner is really hanging out there. Looks like you were on the hairy edge of that thing popping out of there completely while the engine was running. Hope the new timing set takes care of all that.

-

Engine Timing Cover

Yeah, that definitely doesn't look right. Something wrong with the chain and tensioner, etc. Chain stretch, guide wear, gear wear... All together is allowing the tensioner to be waaaaay too far out. I think you need to pull the valve cover off and probably do a whole timing set. Easy at this point since you're in so far already.

-

Barefootdan's 280z Build

Well lets see... If adjusted properly and working as designed, absolutely none of those items should have any effect at all at idle. Charcoal can - Disabled at idle EGR - Disabled at idle BCDD - Disabled at idle Cold star valve - Only active while cranking the engine, so disabled at idle

-

Barefootdan's 280z Build

About the spring compression tool... You won't be able to use the "hooks on the cam" version if the cam is removed. (Duh.) Here's some pics of my latest valve spring took contraption. A little faster to use than my previous contraption since there's less wrench turning:

-

wide ratio FS5W71B slipping out of 3rd & 4th

I spy something... Old Honda maybe?

-

Just Another Damned Z Car Project Thread

LOL. I think he woke up not just thinking about one, but in fact, he work up WITH a Disney princess. I think you get significant bonus points for that!

-

Engine Timing Cover

Unrelated to the harmonic balancer key, but I got a question. Your timing chain tensioner is really sticking out pretty far... Is the head off, or is everything up top still in place? Timing chain wrapped around the cam gear and everything? if the answer is "yes, everything is installed and engaged", then I think it's time for a new timing chain and guides.

-

Barefootdan's 280z Build

Well you've got two obviously bent valves, and marks on other pistons as well. That makes the whole top end suspect to me. The point is, the compression numbers may be more related to issues in the top end than the rings. However... You're this far in and it would suck to do a bunch of work on the top end and put it back together with a tired lower end. Who would ever do such a thing.

-

Barefootdan's 280z Build

I take it back. Other than the valve dents and occasional other minor blemishes, those pistons don't look bad at all. If you don't have a really good condition other option, I'd run those. Must have been a trick of the camera. I was really expecting serious destruction. And you can see the sizing numbers now. Not cylinder number. It was just luck that the only one you could see before was #3.

-

wide ratio FS5W71B slipping out of 3rd & 4th

I think someone did something like that... @zKars maybe?

-

Barefootdan's 280z Build

Oh, and about the number stamped on the top of the pistons... The stock pistons should have a number on them, and there should be faint stampings on the block deck surface for each cylinder and the numbers should match. At least the first number. The stock stamping numbers represent "size", not "location". That "3" stamped in your piston does not look like a stock stamping to me though. Here's a couple pics from my engine:

-

Barefootdan's 280z Build

Well there's your problem!! Nice to find the smoking gun. Good luck with the project. So you were talking about the condition of the rest of the pistons... Maybe it's just the camera or deposits on top of them, but I don't like the looks of them at all. Other than the dent, number 1 looks OK, but the rest of them worry me. Pitting on top? Detonation maybe? Is it a trick of the camera? Are all the rest of them smooth metal underneath the crud?

-

Golden Anniversary - Safari Gold Style

-

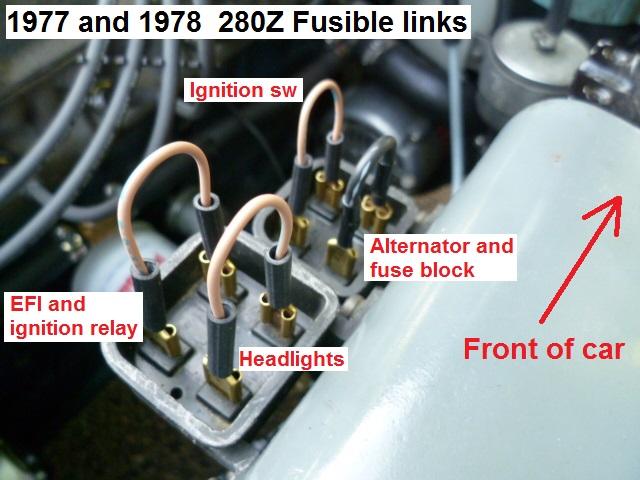

1977 280z EFI Nightmare

Yes, read through the EFI bible. And then read through it again. Compression test. Intake manifold vacuum test. Fuel pressure test. Ohmmeter tests. Ignition timing test. And if you have a few extra minutes, clean some connectors. If you're looking for a place to start, start in the passenger footwell where the heater core leaked and corroded the connectors on the passenger side of the trans tunnel. Also do the temp sensor, the AFM, the fusible links and the fuse block. There are other people who can add much more value about the transmission and driveshaft stuff than I can. I could survive in the wild there if I had to, but there are other people who are experts in that area that will cover you there.

-

1977 280z EFI Nightmare

LOL. Glad to help my friend!! I'm just a guy with a Z who types a lot, but I try to add value where I think I can.

-

Tranny/Diff Ratio and RPM @ Speed

LOL. I like it!

-

1977 280z EFI Nightmare

IMHO, I think the two first steps would be to a) make sure the electrical connections to the EFI system are clean, tight, and making really good connection. Paying special attention to the temp sensor and the AFM, and b) simplify as much of the tubing as you can in order to minimize vacuum leaks. After you have simplified and gotten the basic system leak free and running well, you can start adding stuff back in. For example... For now, you can just cap off all the stuff running to the carbon can. You can also take off everything having to do with the AAR. The car will idle low until it warms up, but once it's warmed up, the AAR should be doing nothing anyway. I don't remember what they use the TVV stuff for... If it's EGR and EGR only, then you can cap all that stuff off too. Just trying to minimize all the tubing because each end of any tube is a potential vacuum leak. Make it leak free, get the basic system working, and then start putting stuff back on.

-

1977 280z EFI Nightmare

Here's some pics of the throttle body. You can see there are two small vacuum tube connection nipples on the bottom. The nipple on the left in the pic (points toward the radiator) should run to a "T" and from that T, it runs to both the carbon can and the distributor vacuum. The nipple on the right points downward towards the rear of the car is used for the EGR system (and only the EGR). So if you've removed the EGR stuff, you can cap that one off completely. Here's a closer-upper of the nipples. You want to use the one on the left and cap off the one on the right.:

-

1977 280z EFI Nightmare

The PCV hoses, while kludgy, are connected fine. The valve cover is correctly connected upstream of the throttle butterfly. Two things catch my eye quickly... First, your fusible links are in the wrong locations. You've got the large BLK link in the back position, and it should be in the front position. It won't explain the performance issues you're having, but fix them now before something goes wrong. They should look like this. The largest link should be the front outboard position: Second, I'm not liking the tube connected to the vacuum port on the bottom of the throttle body... There are two vacuum connections on the throttle body, one that points toward the front of the car, and one that points towards the rear. The one pointing forward is for the distributor vacuum (and carbon can). The one pointing to the rear is for the EGR system. What I'm not liking is there is a hose connected to the vacuum nipple that is pointing rearwards, but you've removed the EGR system. That nipple should be capped off with no tube attached. The hoes you have connected to it seems to wrap around underneath the throttle body, and my suspicion is that you're using it for distributor advance. Is that the case? And lastly... The temperature sensor is often the culprit in lots of EFI issues. Have you taken meter measurements to make sure it's working properly?