Everything posted by Captain Obvious

-

Mustache bar bushings

Hi Kats, Thank you so much. I'm humbled and honored and I'm just trying to help out where I can.

-

Mustache bar bushings

Well I wasn't there at the factory when they were swaging those bushing, but I suspect they did it in just one step. Keep in mind, however, that they have access to machines and processes that I don't. I'm also sure they heat treated their dies, and I did not. I started with a mid-hard heat treatable steel that I could heat treat to a very suitable hardness, but I figured I'm only going to be doing this a couple times, and even without the heat treat, my dies should outlast me. So IMHO the bottom line is that I think it's possible to do it in just one operation, but I wouldn't recommend it unless you really know what you're doing (and I do not). However... After going through this, I believe that I can simplify the die design. You see... The first flaring die did such a fantastic job of tapering the material outward that the curved section of the second did never even made contact with the bushing wall until the flange was pressed completely flat. In other words... The complicated portion of the second die (the carefully radiused and polished center section) is pretty much unnecessary and that second die could look just like a donut with a hole in the middle. That raised portion isn't even necessary. In fact, I believe I could have simply flipped my tapered first die over and used the flat side to press the flange to it's final position. I think that if designed properly, you could get two forming operations from two different sides of the same die. So, if you're looking to minimize the cost of having dies made, I would try that. Here's a pic at the very start of the first tapering operation: And here's how it looks fully tapered with just the first die. You can see that the material is "rolled outward" so far already that it never even contacts the curved portion of the second die: If I had known that a the beginning, I may not have even made two dies. I may have made one "reversible" die instead and saved myself that polishing time.

-

What are you doing to get ready for ZCON 2018??

Haha!! I looked for the MRI on this computer and it's not on here. I've got the disk somewhere and I'll see what I can do. I'm travelling for a week starting tomorrow, so I'm likely to disappear for a couple days off the forum, but when I get a chance I'll look for the disk.

-

Mustache bar bushings

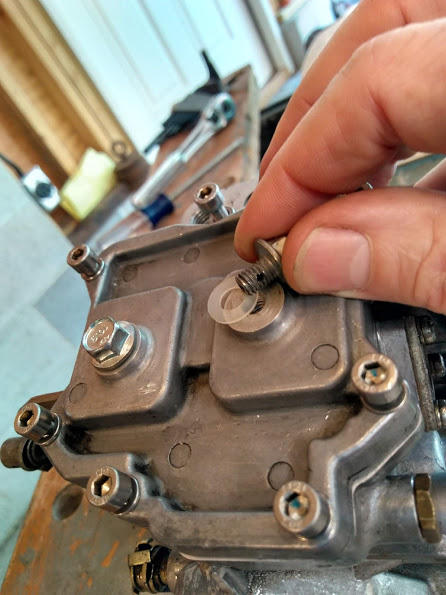

The old single flange design would be a lot easier to replace (because you just press the old one out and press the new one in. The later two flanged design is a little more involved. This is what I did. First, I cut a bunch of slots in one of the flange ends with a thin cutting disk: Then, using a couple punches and a hammer, I peeled up the "petals" of the flanged lip. Worked my way around the bushing: Once those petals were peeled up, you can push the old bushing out of the bar and press the new bushing into place. No pics should be required for those two steps. In order to form the second retaining flange on the new bushing, I made a pair of press forming dies for the hydraulic press. Here's a pic of a new bushing and the dies I made. I made two dies to form the flange in two steps. First flaring step is a simple taper (on the left), and second step flattens the lip after the taper die has bottomed out: Here's another view of the dies. Preliminary taper form on the left, final form on the right.: Once the new bushing is pressed in place, I used the preliminary form to flare the metal outward: And then once the flare was formed, I switched to the final form die: And finished the flare flat into the retaining flange:

-

What are you doing to get ready for ZCON 2018??

So that is "What are you doing to get ready for ZCON 2018??" Woof. That's no fun. Mine are screwed up too. Should I bring my films to compare?

-

Stalling issue(under throttle)

Ztherapy is on the web here >> http://www.ztherapy.com/ I'm sure you can buy the SU video from them. If you hit the "customer support" link, and then hit the "video" link, there's some talk about costs and stuff. But best to call them and order it over the phone. I'm assuming this is the clear tube measurement you mentioned with the coat hanger? So you're on Marco? My neighbor just got back from there. Her was there for two weeks for vacation. Told me it was fantastic!

-

Mustache bar bushings

Yeah, I'm no expert on the bushing lineage, but I'm not so sure about that either. Have you seen a picture of that kind of bushing?

-

Mustache bar bushings

That's exactly what I thought you were describing. So to me, it looks like someone has removed (burned, grounded or something) the rubber portion of the bushing and left the outer metal shell installed. In other words... That looks like the two flange bushing style that someone has eviscerated, presumably in preparation for installation of poly bushings. I believe the process would be to cut (or peel up straight like a banana) one of those flanges off and then press the bushing remnants out of the bar. Once you do that, you should be able to press the new ones in.

-

Mustache bar bushings

I know what you're referring to, but if that's the case, then I can't explain this: "However it seems my bar is the earlier type, which is 'double flanged' from the factory. has anyone cut a flange off and pressed the rest out with this earlier bar?" It sounds like he's describing a later style bushing which is flared on both sides. If it wasn't flared on both sides, you wouldn't have to cut anything to press it out. Picture is worth 1000 words

-

Stalling issue(under throttle)

LOL. I do get down to Boca every now and again, and I already looked up the travel time at about two hours each way. Have you verified (using the clear tube method) that your float levels are close to spec?

-

Mustache bar bushings

I'm not sure I'm understanding what you have going on there, but... Are you sure it's not just the old remnants from previous factory bushings still installed in the moustache bar? Lots of people burn or grind out the rubber portion and leave the outer metal shell intact as preparation for installing poly bushings. Have you got any pics?

-

Stalling issue(under throttle)

There should always be a small amount of slop in the linkage so the pedal itself is never holding the carbs open. So, "sloppy loose" may be too much, but "some play" is correct. The center screw up on the balance tube is "idle speed", and the screw on the rear carb is "idle balance". The screw on the front carb is only to control how much "throttle boost" is applied by the throttle opener system, but since your throttle opener system is completely disconnected, it should have no effect. When you say "rich-lean screws" what are you talking about? Are you talking about the nozzle height adjustments under the carbs? Sure wish I were closer... We'd have you fixed up in short order.

-

What are you doing to get ready for ZCON 2018??

Those are the later versions that I've reworked. Yes, those bosses were originally intended for attachment of the small heat shields to the undersides of the carbs, but I repurposed them for the bowl drains. Milled them flat (for a good sealing surface), drilled through, and tapped. I don't think I've ever seen a pair of really early flat tops with my own two beady eyes, but it appears from the documentation that those bosses have been there since the beginning. Here's a snippet from one of the docs where they compare the old and new style float bowl covers. First (early) design on the left, and second (later) design on the right. The first design cover is flat on the outside, while the later design is not flat on the outside because they have the recessed pools for additional fuel. But they all have the heat shield mounting bosses: And about the floats... The float design is very different between first and second designs and I don't think there's any possibility that they are interchangeable. And even if you find you CAN physically mount the wrong design into place, I don't think you want to do that. On the early design, the float mounting ears are on the inside surface of the bowl cover, while on the second design, the float pin goes through the body of the carb itself and is sealed with the brass hex cap. Completely different. Here's a snippet from the docs that shows the differences between the two. New (second design) on the left, first (original design) on the right:

-

California Fires

Well I hope everything works out OK. That's no fun at all.

-

What are you doing to get ready for ZCON 2018??

Haha! Bowl drains to help with things like carb adjustments and tuning (things like float level and fuel pump testing) and draining for off-season storage. What I was just doing a couple days ago was replacing the copper washers with nylon because the copper was too hard and it took too much torque to get them to seal. I switched over to nylon for a better seal. Here's a pic of the screws with the previous copper sealing washers: Now with the nylon, dry as a bone at a completely reasonable torque:

-

Stalling issue(under throttle)

If your original issue was the engine cutting off and the tach dropped to zero when it happened, then the main issue isn't (wasn't) the carbs. Someone's got to have good pics of using the clear tube to measure the bowl level. Anybody got a handle on some good pics or videos? I'll ask again for someone out there to loan out a copy of the Just SU's video... Anyone?

-

California Fires

Wow. That's no fun. I'm assuming you personally aren't at high risk where you are? Not much to burn in the desert?

-

510 Parts Near Wilmington Delaware

Good. Then my work here is done. Here's to hoping those parts found a good new home.

-

What are you doing to get ready for ZCON 2018??

-

Stalling issue(under throttle)

That's too general. There are lots of things that could cause a necessity to run four turns down. And now that the floats have been "rough set" using mechanical means, the only way to truly be sure the level is correct is with a clear tube to actually view the bowl level. Everything else is just a guess. I think that would be the best thing... His location is near Naples, FLA. It would be great if there was a kind forum member not too far from there who was willing to stop by and lend a hand!

-

510 Parts Near Wilmington Delaware

Haha! I think you did. I could just make a pile of stuff behind her Porsche. She wouldn't be able to get her car out of the garage, but I'd just blame it on you. LOL. Seriously though... I'm headed out of town shortly and have very limited discretionary time between now and when that shed is supposed to disappear. So at this point it's more an availability thing than a storage place thing. I don't think I have time for a parts run.

-

510 Parts Near Wilmington Delaware

Call me if you want. I'll put SWMBO on the phone. YOU can ask...

-

510 Parts Near Wilmington Delaware

He added the price of $400 to the ad. He also added some pics. It was the "motivated sounding" words in the ad that caught my eye... Words like "Disposing of" and "shed will be removed".

-

Stalling issue(under throttle)

I would change as little as possible and work on one thing at a time. Don't put in any other significant parts (like a new coil) until you have a handle on where you are now. Someone please lend this guy a copy of the just SU video? Any kind member in the Naples, FLA area that can lend a hand?

-

510 Parts Near Wilmington Delaware

LOL. Well I'd check it out if I were a 510 owner. Like a 72 510 wagon. Haha! Gold mine. Goose chase. Gold mine. Goose chase.