Everything posted by Captain Obvious

-

My Throttle Cable Conversion

I did a couple different iterations up at the throttle body. The first version was to make a new piece of linkage that fit onto the original throttle that allowed for the use of the cable. And things spiraled out of control from there. The current (and hopefully last) revision is to convert over to a Nissan Sentra throttle body that originally used a cable pull. Let me look back through my pics and see what I have.

-

1971 HLS30-14938 "Lily" build

-

Arrows on the factory U-joint castings - what do they mean?

Yeah, that's done for. I'm no bearing expert, but I believe that's known as "spalling". However, at this point, if it were me, I'd take the opportunity to check the body hardness and see if it was ever a possibility to drill and tap. I gots to know.

-

Heater Core Alternative - Escort Core into 260/280

I think they ran into a couple issues with the AAR operation. First issue is that on a very cold day, the cold air going through the AAR may have prevented the AAR from closing completely. In other words, the heating coil may have been overwhelmed by the cold air stream. Second issue (and one that I have experienced myself) is the rapid cooling off of the AAR. Park the car and run into the store for a couple minutes... When you come out and start the car, the idle is bumped up again because the AAR cooled off. The thermal mass of the heating plate and the water slows that process down and prevents that. That's my read.

-

Starter with some extra in/outlet? What is this!!???

Yeah, I don't remember where I first learned that, but it's a thing, Ozone is unstable and breaks down quickly in our level of the atmosphere, but it's definitely a thing! So I would surmise those vent holes are to prevent any pressure differential between inside and out side of the starter motor from causing a problem. Whether that pressure differential is from ozone or simply from just heating up the air space inside the starter, but you want to let it breathe.

-

Starter with some extra in/outlet? What is this!!???

Serious. The electrical arcing in the motor brushes creates ozone. Here's a snippet from wikipedia >> https://en.wikipedia.org/wiki/Ozone Incidental production: Ozone may be formed from O2 by electrical discharges. Unsuppressed arcing in electrical contacts, motor brushes, or mechanical switches breaks down the chemical bonds of the atmospheric oxygen surrounding the contacts. Certain electrical equipment generate significant levels of ozone. This is especially true of devices using high voltages, such as ionic air purifiers, laser printers, photocopiers, tasers and arc welders. Electric motors using brushes can generate ozone from repeated sparking inside the unit.

-

Tachometer Function Question

Well not exactly. You're correct about the early tach running the coil current through it, but it's not reading it like a ammeter. It's reading pulses. Steady state does nothing. The signal has to change. If your points happen to be closed when you turn the key to the "ON" position, if it was an ammeter, the tach would peg high and stay there until the points opened.

-

Heater Core Alternative - Escort Core into 260/280

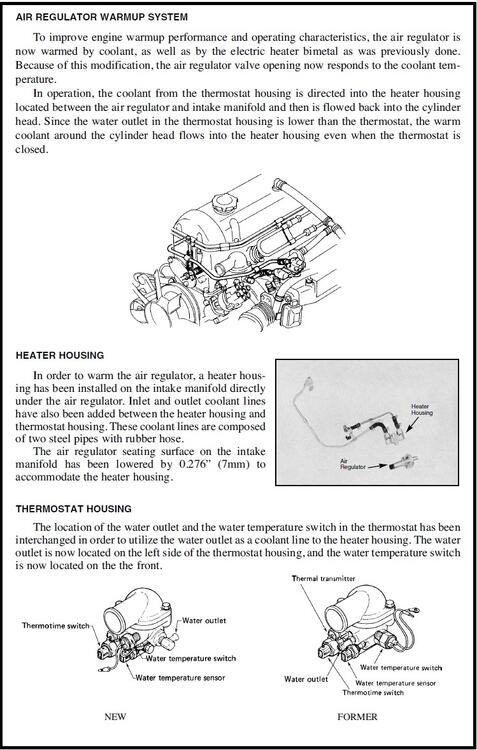

In 74, they bypassed the thermostat by pushing coolant through the carb system. In 76, they bypassed the thermostat by pushing coolant through a little heating plate that lived under the AAR. In 75, they did neither of those, so they bypassed the thermostat by putting that little bypass line in. It appears that coolant path in 75 didn't serve any other purpose other than to bypass the thermostat. Here's a snippet from a 76 Service Bulletin where they discussed the changes from 75 to 76, Here's where they talked about adding that little heating plate under the AAR: So in 76, they killed two birds with one stone... They fixed an issue with the AAR not operation correctly under all conditions, and they also fixed the issue of the stagnant coolant pool under the thermostat.

-

Ignition Switch Broken Wire

Actually, I don't. My data points are the most of my experience is with the later switches and my believe that they didn't ADD stuff like this in later years, only Munced down from earlier versions. I do know that I've got original switches from years as early as 74 as well as aftermarket stuff as new as a few years ago and I've never seen one with that kind of cover over those wires. Sorry if I appeared more confident than I really am. Maybe I've been missing that cover off all the switches I've messed with!

-

Clutch Master Cylinder Piston "Stuck" Inside Bore

@Patcon, Didn't you tap a hole in a master cyl for some reason? Don't remember if it was brakes or clutch, but I do remember you doing something like that.

-

Starter with some extra in/outlet? What is this!!???

In all seriousness, I would assume it's an air vent to let the ozone out?

-

Starter with some extra in/outlet? What is this!!???

Home Before Dark!!

-

Temp sensor resistor

Well one difference between adding a resistor to the temp sensor circuit and messing with the AFM is you can only make it richer with the resistor, not leaner. By messing with the AFM, you can (in theory) do either. So out of curiosity, Is there a problem here you're trying to fix? Or is this an academic discussion only? And... Where did you read that?

-

technoversions tachmatch voltage booster

I've wondered the same thing, but I don't have a spare tach here for analysis. If someone wants to send me a later design tach for investigation, I'd be happy to put it on the operating table.

-

Heater Core Alternative - Escort Core into 260/280

@HusseinHolland, Yeah your car left the factory without air. Your HVAC system is all manual. All cables, no vacuum,

-

Heater Core Alternative - Escort Core into 260/280

I wasn't there when they designed it, but my theory (based on my own experience*) is they found that the thermostat housing was completely dead-ended in 75 when they switched from carbs to the FI. You see... The carbs had water that ran through the intake manifolds and other locations depending on the year, but in 75 that all disappeared. In 75 if it weren't for that "bypass" the thermostat housing did not see any flow until the thermostat opened, other than the little hole in the thermostat. I'm thinking the hole in the themostat wasn't enough flow and they noticed that the engine temp got hotter than desired before the thermostat opened (because it was sitting in a stagnant pool of cold water). Then in 76 they piped it through the heating plate under the AAR. I'm thinking 75 was the only year they needed to put in a bypass simply for the sake of a bypass, * I'll go into it if anyone is curious, but not really necessary for this discussion.

-

Happy Anniversary To Us!

Me too!! Hopefully we'll be able to get the band back together soon!!

-

Z Cars On TV And In Movies

LOL!! Looks like me!!!

-

Ignition Switch Broken Wire

Well you could always just cut (break) the plastic cover off the switch. At some point in the evolution they decided that cover wasn't necessary anyway. And if you're still skittish about it, you could just wrap a couple rounds of tape around the whole switch body to recover it after you've reattached the wire?

-

Heater Core Alternative - Escort Core into 260/280

Hard to tell from that pic... Start simple. Take a pic of your HVAC controls. Does it have a setting for A/C or not? Here's a pic of a non-AC control head: And here's an example what it looks like if you have factory air:

-

Ignition Switch Broken Wire

The later versions of that "key in the ignition" switch that I've messed with don't have that plastic shroud over the connections. Not sure if they changed the design over the years, or if the ones I've messed with had the cover removed by a PO at some point. In any event, these pics should help. Start with this: Remove this. Should pull off by hand: Then remove this. Should come off with some light taps: Where to go after that should be obvious:

-

Restoration of BringaTrailer 240z - HLS30-35883

Yeah, it sounds like you hit the limit of your press capacity. That's exactly how it feels when you hit the pressure limit. Why don't you give SteveJ's 20T a try? Always fun to have someone watch over your shoulder you as you sweat nervously while you have something under 19.5T of pressure.

-

Arrows on the factory U-joint castings - what do they mean?

I suspect the U-joint spider is heat treated and would be difficult to drill and tap. Depends on how hard they made it. I know the tips where the bearings contact have to be quite hard. The body doesn't need to be that hard. but unless they selectively hardened the tips (inductive heating), the whole body would be hard. I'd hit it with a file first to see how hard it is. If the file just skates, it's a tough job to drill and tap that.

-

Z Car Club Association ZCON 2023

I'm guessing that @Patcon uses the same "show me all of the new activity in the past 24 hours" feed that I do. And since they all occurred in the past 24 hours, all of them show up. Between the two recent topics, I get six of them. I thought you were having internet troubles and were getting duplicate posts. I certainly didn't think you did that on purpose. Before people replied to some of them and split them up, I got just about a whole screen of it! "Fairlady Z's topic in USA Eastern pic in USA Western y Z's topic in Canada d a topic in Canada a topic in USA Eastern in Maryland Z Club's Discussions"

-

1970 240Z Works Rally - the road to restoration

Well without spending real time on it, that's about all I have from a distance. Have you found a shop willing to take on the work? In my experience with such devices, the amount of time/expense required to diagnose and fix something like that is very rarely worth the dollars. In this instance, it's a piece of history that is irreplaceable which makes the value indeterminate. And one of the problems is certainly going to be obsolete and unavailable parts. I already looked around on the interwebs for the output transistors (the four big ones bolted to the aluminum plate) and they are (not surprisingly) unavailable. PNP germanium in a TO-3 case. Riiiiiight. Haha! Send me a PM if you're still looking for a shop and want to chat. I could use some vapor blasting. Or some $$. Or a some of both.