Everything posted by Captain Obvious

- 1978 280z: Tail Lights, Dash Lights, and Side Markers not coming on/not working

-

1978 280z: Tail Lights, Dash Lights, and Side Markers not coming on/not working

12.45V is just fine. As for keeping it cool, I suggest ice cubes. However, if you don't like the wet spots on your pants from the ice melting, you could rig up a small can of R134 and open the valve a little every now and then. Seriously though... That desoldered wire is obviously the result of a fault somewhere generating way too much heat. The issue is if you haven't figured out what the original fault was, there's the risk that it happens again. My first guess would be failing burned up switch contacts inside that switch you pictured. I don't want you to put it back together now and then just have it happen again in a couple weeks.

-

Triple carbs for stroker motor

I've read on the internet that David was messing around with custom roller rockers for the L-series engines. I also read on the internet there were some reliability issues. Do you know anything about the stories? PS - And apologies to the OP for the distraction.

-

1978 280z: Tail Lights, Dash Lights, and Side Markers not coming on/not working

Well THAT doesn't look right! Haha! Couple thoughts. First, before you bother to reconnect that green/blue wire, have you verified that wire actually has the correct battery voltage on it? Should have 12V on it when measured to chassis ground. And second... If that wire got so hot that it desoldered itself before, do you know why? And if so, have you changed something to prevent it from getting that hot again?

-

Preventing rust in the Z's lower front fenders

Actually POR-15 claims to be flexible. Here's a snippet from their website: POR-15® Rust Preventive Coating is an effective anti-corrosive and rust preventive coating that offers superior chemical resistance due to its dense, cross-linked molecular composition and non-porous attributes. It has the opposite chemistry of ordinary paints. Now add to that POR-15® Rust Preventive Coating incredible hardness, toughness, and flexibility and you have a coating that is practically indestructible. Clearly they can CLAIM pretty much whatever they wish, but "flexible" did make it into their marketing pitch.

-

1977 280z EFI Nightmare

Gotcha. Out of curiosity, did you run the same test (using the ECU) to drive the replacement injectors before you stuck them in? Or was it just faster and easier to toss the replacements in and give it a whirl? Glad you were able to get his car running better!

-

Putting in a replacement L-28

Agreed. Maybe not quite as good as the OEM, but it's probably "good enough" either way.

-

1978 280z: Tail Lights, Dash Lights, and Side Markers not coming on/not working

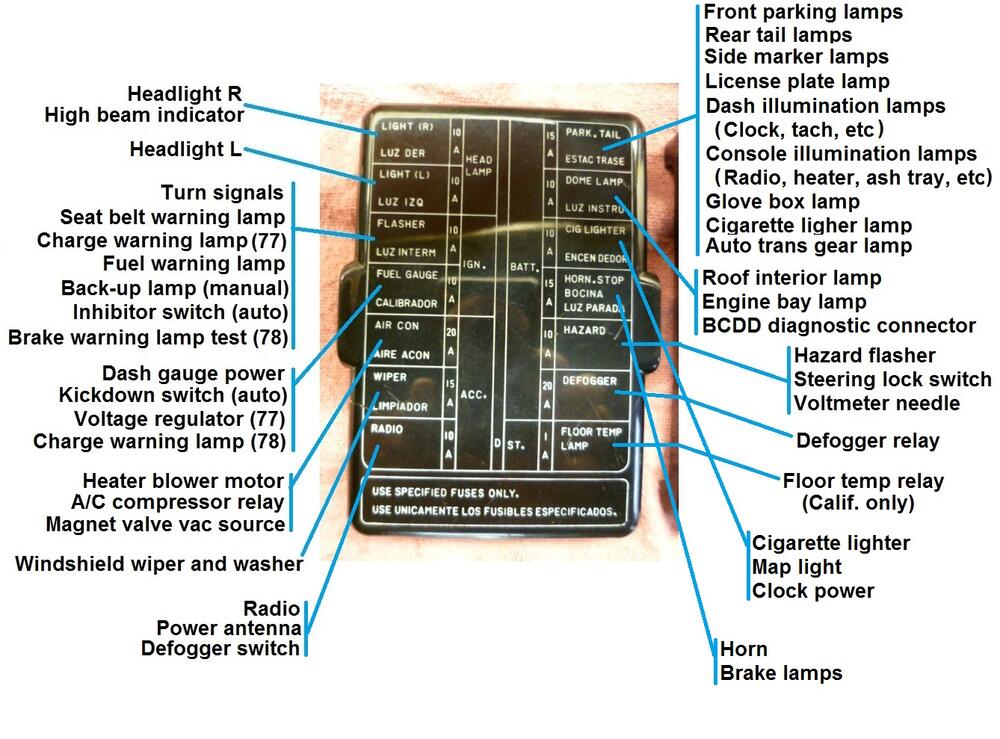

What Steve said. The GL over at the steering column should be hot at all times. If it's not, you need to move upstream towards the fuse block. And you don't need to check fuses by swapping them into other locations... You've got a meter, right? I bring that up because I can picture a scenario that goes like this: You pulled the (burned out) park/tail fuse and stuck it into the cigarette lighter position. Then you checked the brake lights and they still worked. All completely true statements, but tells you nothing about the integrity of the fuse that came out of the park/tail location. Not saying that's what happened, but simply saying it's possible. Here's a rough non-pretty layout of what fuses do what for the 77 and 78 years. Might help a little?

-

Putting in a replacement L-28

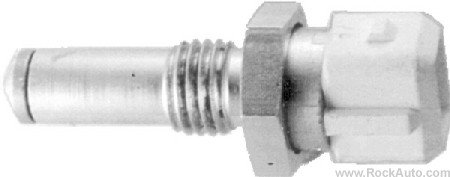

I think the reason they did the spinny nut on the ZX version is for better thermal conductivity between the head casting and the sensor tip. I think sensor tip is designed to bottom out in the dry hole against the aluminum of the head. And they did that spinny nut thing so you weren't scraping the sensor tip as you tightened the nut. You could hold the sensor from rotating while you tightened the nut. Of course, that would also make it such that the spinny nut would not necessarily bottom out against any sort of sealing washer. I wonder of they used an O-ring seal there instead of a brass crush washer. I've got some ZX stuff around here someplace and if I can find it, I'll take a look. In any event... If you filled the hole with thermal conductive goop it would probably be fine. I can't believe the head temp changes that fast and I can't believe there would be a huge thermal gradient between the head and the sensor regardless if it bottomed out or not. But I wasn't there when they designed it.

-

1977 280z EFI Nightmare

Awesome! Glad you got to the root of the issue! You said "They wondered if it was the injectors so they did full spray tests into graduated cylinders for fuel flow, consistency, and volume, and it looked totally fine." Did they run that injector flow test on the car, or on the bench? I'm wondering if they used the 's ECU to drive the injectors, or a stand-alone injector tester rig designed to check things like that.

-

Putting in a replacement L-28

I just nabbed a pic off rockauto that shows the original ZX version with the spinning body: That said... The part above was the only one that looked like that. Most (all?) of the other aftermarket stuff looked like it did NOT have the spinning nut and could be used in either a wet or dry hole.

-

Putting in a replacement L-28

I don't know about the aftermarket stuff, but the original OEM ZX sensors are a little different in the way they mount... On the Z version, the brass body portion is all one piece and the electrical guts are crimped to the body to finish the assembly. In contrast, on the ZX version, the tightening nut spins independent of the sensor body. The "body" portion is two distinct and separate pieces. Why does that matter? Because if you use a ZX version with the spinning nut in a wet location like the Z thermostat housing, it will probably leak through the seam between the body and the nut. You could probably use a Z version in the side hole in a P79 or P90 head, but I would be wary of the converse of using a ZX version in a Z thermostat housing. That pic above of the aftermarket ZX sensor looks like it's made pretty much the same as the Z version, so who knows? Oh, and the connector key is in different locations between the two of them. Not an insurmountable issue, but something to be aware of.

-

Putting in a replacement L-28

I believe the straight threads are just normal metric pitch stuff. The tapered stuff is BSPT, but I think the straight threads are typical metric.

-

Preventing rust in the Z's lower front fenders

Dug up a pic courtesy of @jfa.series1

-

Preventing rust in the Z's lower front fenders

Where do the cowl drains dump out? Do they terminate in the area the you're trying to keep dry?

-

Fuel Line Blockage - New Cleaning method

That's very cool. Great thinking and adapting!!!

-

New owner and already she's a keeper!

LOL! So no bonus points, but it sounds like you don't need them. Beautiful car!

-

New owner and already she's a keeper!

Exactly. Sometimes a cigar is just a cigar.

-

Cool Tool of the Day. (CTOD)

Oh, and by the way... Great minds think alike! Here's some pics of mine I made who knows how many years ago. I used a cheap-o 12-point though because I figured that since I was going to be clamping the crap out of it with vice grips anyway, I opted for the maneuverability instead of the strength: Battle scars on the outside from all the vice-grips:

-

New owner and already she's a keeper!

Nice car! Bonus points* if you're still running the flat top carbs. * Not that it means squat, but it sounds impotent.

-

Connector specifications

Most of my hands on experience is with the later years (280's), and on those, pretty much all the connector stuff on the Z's was made by Yazaki. Logo is sorta an arrowhead and it looks like this: Some of the fuel injection stuff used on the 280's is AMP. But other than that, it's probably Yazaki.

-

Cool Tool of the Day. (CTOD)

Hahaha!!!! I also rotated the pic so I could get a better view of the number.....

-

Cool Tool of the Day. (CTOD)

So nobody wonders why I said that? Nobody is even going to ask? What? Am I the only person out there in the whole world that looked up the part number stamped on the handle on Jim's awesome transmission spinner device? Just me?

-

Cool Tool of the Day. (CTOD)

Well actually, according to Bob Bitchinn, the answer is "two". Apparently he rolls big joints.

- battery drain