-

free fiberglass molds for fender flares and trunk hatch

I want to give away the molds I used to create the fender flares on my car. Also I have molds for the rear trunk cover and rear tailight panel. I'm in San Diego and they would need to be picked up, because I'm moving and I don't want to move them too.

-

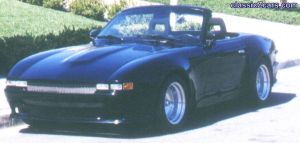

240Z roadster

Anyone wanting info about this car can email me at mjyikes@cox.net I have the molds I used to make the flares, tail lights, trunk panel just sitting at home collecting dust.....anybody want parts ? I will post more pics now that I finally have my new digital camera.

- 240Z roadster

-

72 240Z Roadster

It has a custom fiberglass back deck with a trunk, weatherstripping, remote release, and gas strut to hold it up, work very nicely. Previous Z's that I converted didn't have a trunk, only access from behind the seats and a real PITA to get stuff in and out of. As far as cost, mostly time, I did all of the work myself, made the molds, did the welding, did the painting in my driveway, probably around $4000. in parts and supplies, including rebuilding a 280Z motor, all new suspension and anti-roll bars, and all of the other stuff needed to update a $600. donor car.

-

72 240Z Roadster

Thanks alot guys. I kinda like it too. As you can see in my gallery, it is not the first convertible Z I have made, but it is the last (famous last words). I'm in the process of trying to get a digital camera, then I'll post some more and hopefully better pictures. Any suggestions, on digital cameras ? I need one that takes quick pictures, since I have a four year old and she moves pretty fast. Oh and She always wants to go in the Z roadster instead of the Explorer

-

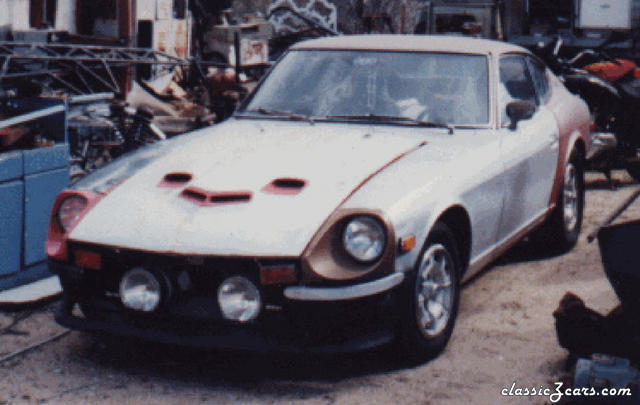

jade z 2

No this is an earlier version that I did and sold about 10 years ago. This one was not flared out, had a standard Z windshield frame, instead of a mazda miata windshield frame, had no working trunk lid, standard bumpers, and actually had a working custom made top.

- 72 240Z Roadster

-

toe-in

Does anyone know the correct way to measure toe-in, without going to an alignment shop ? The manual lists the toe-in for a 72 240Z as 1.59-5.56mm. Is that measured from the leading edge of the tire to the trailing edge, measured at the center height, or is it from the leading edge of the tire to the center of the wheel ? One would result in twice the toe-in as the other.

-

clock replacement

Thanks for the help guys. I tried to see if the motor still worked and it doesn't. It looks like if I can find a cheap 280Z clock and use the internals, it should work well. So I'm off to All Z Auto parts tomorrow morning.

-

Tach problems

I have a '72 240Z with a 280Z motor in it. It has a breaker-less distributor installed by a "professional" shop. The tach doesn't work properly. With the first one, the needle went flying all over the place, then quit. Went to a junk yard and got a replacement and this one only reads between 0 and around 500 when I'm revving to about 4500. I called the shop to confirm that they hooked it up correctly and they assured me that they were the professionals and knew what they were doing and I just happened to get two bad tachs. Is there a special way to wire a '72 tach when you are using a newer distributor ? How can I tell what year distributor it is ? I think it is a '78 but I'm not sure. I pulled the whole dash out today to fix several things, and took the tach apart and noticed one of the little resistors is bubbly and the outside is cracking off. That is why I think it is wired wrong. Anybody ?

-

clock replacement

Has anyone had good luck replacing the clock from a 72 Z with a clock from a newer vehicle or an aftermarket source ?

-

Tension Rod question

Thanks for that reassurance, 2manyz's It seemed to work fine, I just don't like to force something if it's not right. There was no measuring guage for the bushings from Motorsport, would you happen to know that dimension, I'm sure I could call them tomorrow and get that info. The tightening of those bushings would seem to affect the caster, so it's probably important. Also, what kind of paint can you use on the brake caliper, and wheel hub, I don't like rust.

-

Tension Rod question

I have a question regarding tension rod bushing replacement. I am replacing all of the bushings in the front suspension with new urethane ones from Motorsport. As I'm replacing the tension rod ones, I notice that they are about .100" thicker than stock rubber ones (which may have been compressed since I don't know how old they are), and about 10 times as hard. When I assemble them, the holes to bolt the tension rod to the control arm don't line up any more, they are off about 1/4 inch. I could push the control arm forward to get the bolts in the holes but that seems to put an undesirable torque on the new urethane control arm bushings. Is that the way it is supposed to be ? One other question while I'm at it, when I put the new ball joint, also from Motorsport,in the holes do not line up with the control arm holes, off by about .050" but enough so that I can't get the bolts in. The old ball joint lined up fine. Should I take off a little material from the ball joint or from the control arm , any thoughts ? Thanks, Mike

-

Street Racer in the works

- engine

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.