-

Posts

1,332 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Knowledge Base

Zcar Wiki

Forums

Gallery

Events

Downloads

Store

Blogs

Collections

Classifieds

Everything posted by Hardway

-

1971 240Z Driver Build Advice Requested PLEASE

Hardway replied to HappyZ's topic in Open Discussions

As someone that has owned three 240z's and two 280z's, always go with the car with the least amount of rust. Mechanical and interior components are swappable all day long. The white car may not be as pretty as the red on the surface but it is by far a better foundation for a build. I would strip the white car to a point it can be painted the color you want, get it painted, then install the best of everything from both cars. -

Glad to see they are back. I actually didn't do anything. PB had a message on their front page about it but had not thought about it tonight. If it happens again I will re-create the post as I have all of the pictures backed up.

-

Photobucket is experiencing an outage. Yes, I could copy the text and re-create the post with the pictures attached to the forums. May work on it tonight if MNF is uneventful.

-

I will double check my Photobucket account. The pictures should be working as I just paid my annual subscription earlier this month. Thank you for bringing this to my attention.

-

For those of you that follow the Datsun Cars and Trucks For Sale FB page probably saw the car for sale. It was purchased by its new owner yesterday evening and who took it home to Houston. I enjoyed owning the car, refreshing its various components, and learning more along the way. The car is still a blank canvas for the new owner that can be driven as is or taken in any number of directions. My wife and I have some big financial goals we want to achieve in 2020 and the sale of the Z will ensure that happens. I will still check in from time to time to see what everyone is working on. I thank everyone for their encouragement and support.

-

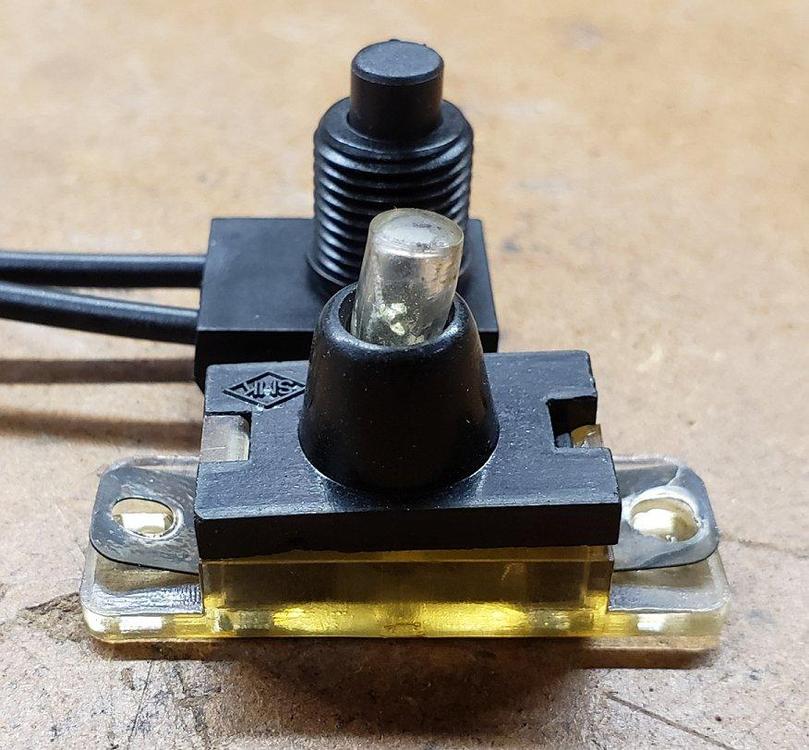

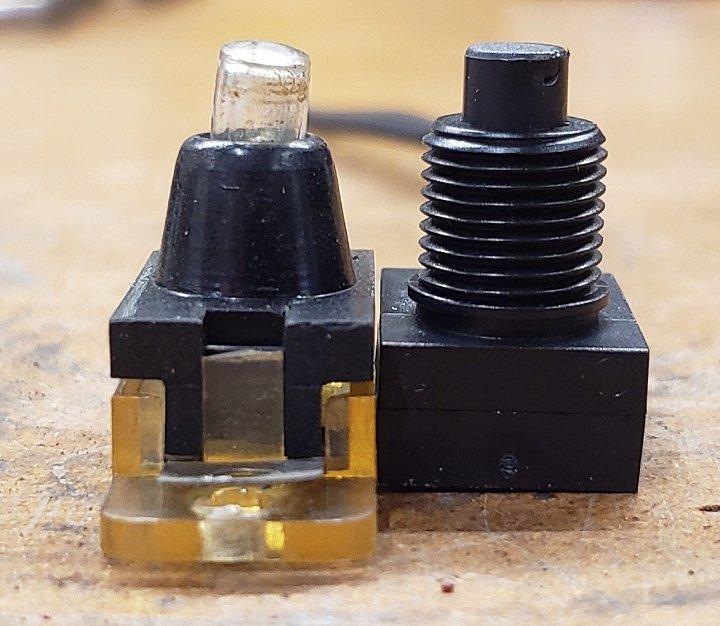

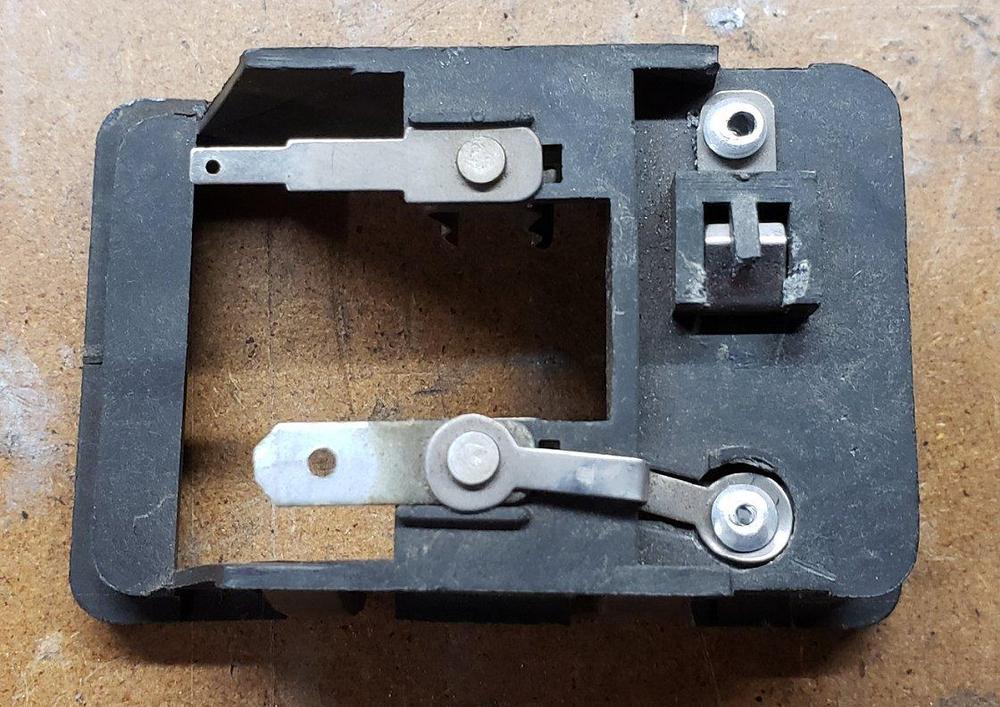

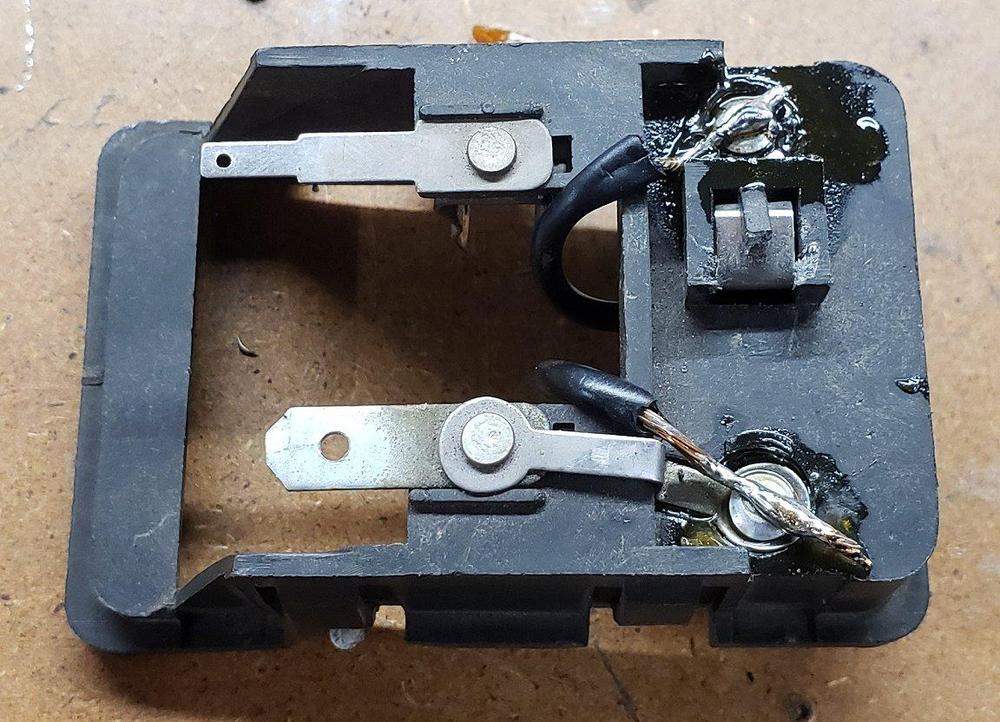

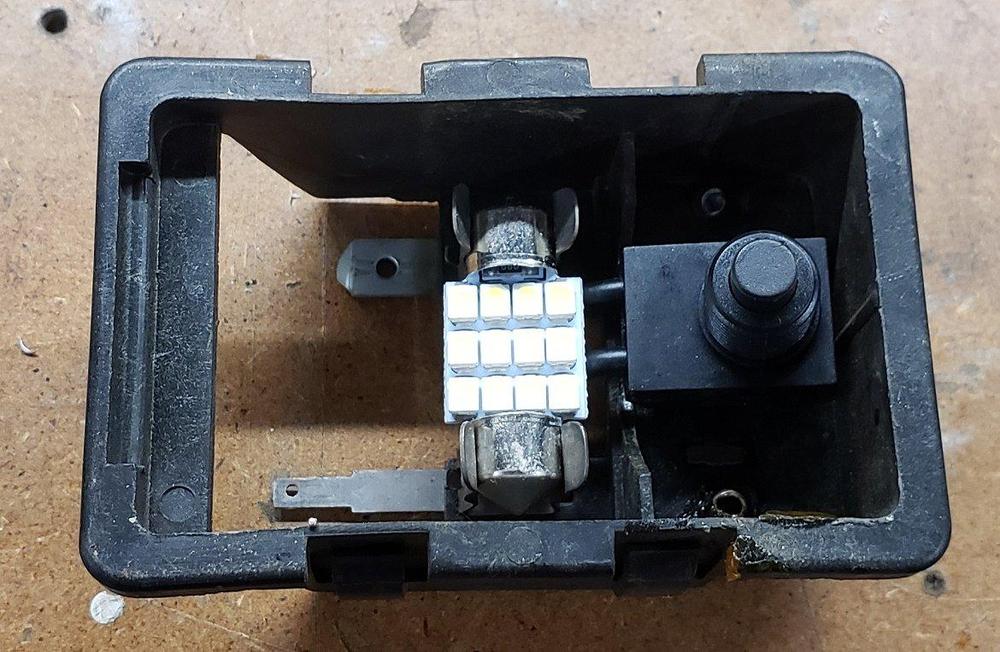

When I removed the rear interior panels for the hatch seal replacement I also had to remove the dome light and trim piece. The dome light has never worked in the car so I wanted to figure out why. A few depressions on the lens told me the switch was not popping back up as it should. After carefully removing the trim piece and lens this was easily confirmed. SMK is still in business and they make of all things, keyboard letter switches. Makes sense but in all my research I could not find this switch or anything close to it by SMK. I would love to know who makes the switch for the NOS units Nissan is selling for $100. There was no way I was giving a c-note for a new dome light so I found these switches on Amazon, 5 of them for $8.68. As always, they arrived in a few days and after some side by side comparisons I decided to move forward. https://www.amazon.com/gp/product/B07LCH1N3B/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1 First I riveted the contacts back to the housing as I had to drill out the spot/swag welds from the old switch. This would give me something to solder to. Looking back on it I wish I had just used some small machine screws and and nuts as I could wrapped the wire around the screw and filled it with solder. Oh well, next time! Then it was just a matter of soldering the wires from the switch to the riveted posts. I had thought about using some double sided tape on the bottom of the switch but I could tell it was not going anywhere, especially once the lens was on. I replaced the old bulb with an LED, again from Amazon and with a quick test I confirmed I had the polarity correct on the bulb and the switch worked. I cleaned up the lens and polished the trim. Upon testing with the lens on I determined I needed to bend the rivets out of the way a little. With the action feeling good I installed with and basked in the glory of my handy work. The light works when either door is opened and works via the switch. Job done!

-

With the new hatch seal in place I decided to tackle the other common cause for exhaust fumes entering the cabin, the tail light gaskets. I had done this before on my series-1 car so I knew what I was in for. I went with a set of Precision gaskets for $50 shipped from a DPAN member. If this was going to be a fully restore car at some point in the new future I would have gone with OEM Nissan seals but they are currently $120. The project was straight forward and as expected the Precision seals are not perfect as some of the grooves do not line up. I would say they are about a 90% fit. While I had the trim panels off I decided to scuff and paint them with some Rustoleum Flat Black. They appear to have had multiple layers of paint and after a lot of find sanding I was satisfied. Next I took some fine steel wool to the stainless trim and that really brightened them up. Finally they were prepped and masked for paint. I spent about 45 minutes laying down 5 thin layers of paint. The end result was not perfect but a 10x improvement over the splotch job that was on it. As I reassembled everything the bottom of the trim panels would not stay in their clips. This is due to the new seals so I improvised with some heater hose to push against them until the seals develop some memory. I plan to leave them in place for a few weeks and them remove them. I also ditched the Nismo license plate frame as it is not a vintage piece. The Texas Tech bumper stick has to stay for now as I am sure its removal will create another project. All in all I am happy with the result.

-

As I have been driving the car more in effort to tune the carbs, the exhaust smell was becoming too much so I decided to start with the hatch seal. The seal on the car was well past its prime. Before starting to remove the old seal I removed the rear interior panels and quickly discovered the highly probable cause for the occasional raw gas smell I would get, a broken plastic vent hose coupler. A quick search on Amazon got me a new brass piece to my door in a couple days and was quickly installed. With the old seal removed along with all the residue I could scrape off I took some measurements and ordered 25ft of seal number 1120A832 from McMaster Carr. Knowing I or someone else would paint the car in the future I wanted something that could easily be removed but still seal up in the mean time. While I waited for the seal to arrive I successfully re-glued the outer seal at the top of the hatch opening. I also wire brushed and sprayed some rust encapsulator on spot that were under the seal. Once the seal arrived I spent about an hour installing it as it requires strength and finesse. The seal seems to work very well as it has some real cushion but still allows the hatch to close with ease and is not pushing it up.

-

Good afternoon fellow Z owners! Working through an issue on my '72 240z that seems to be somewhat common but with no common solution. Engine does not run smooth, shakes at idle, ignition timing set to 9 degrees BTDC at 900rpm. When accelerating under load it pops and backfires but not all the time. Fuel system is set to 3psi and per the gauge runs this all the time. I am running a Mallory 2363901 distributor with the UniLite electronic ignition module. Tach works in car. Baseline: Key set to Run, Battery = 12.14V. Using an Accel Super Stock coil 8140C. Mfg spec is 1.4 ohms Primary and 9.20K ohms secondary. Mine reads out 1.7 Primary and 11.61K Secondary. I was using an older MSD Blaster 2 coil but its Secondary resistance was over 2x the Mfg. spec. Power going to ballast blk/white wire = 11.08V. On the other side of the ballast grn/wht wire = 6.36V The positive blk/wht wire on the coil when pulled off the coil is 11.80V but when plugged on to the coil = 5.49V The condenser is also connected on the other side of the + side of the coil. The solid black wire on the negative side of the coil produces a solid tone of continuity when grounded to the car and when it is connected to the coil. 1. Is the voltage drop on the + side of the coil expected with the power wire is connected to it? 2. Should I be seeing 12V on the power side of the ballast instead of 11.08V? Is the drop of approx. 5V through the ballast expected? Do I still need the ballast since I am running electronic ignition? 3. Do I need to have the condenser attached on the + side of the coil since I am running electronic ignition? 4. Do I need to buy a new coil at this point? Thank you in advance!

-

I took the Z for a test drive and I am really happy with the results. The car still handles well but now it actually has rear suspension travel so it rides nicer but is still on the firm side. Visually, I think it looks 100x better. The sunken rear suspension just let the car down and now it looks like the wheels fit the car and have some room to breathe. Below are some before and after pictures. What do you guys think?

-

With the struts wrapped up the rear brake hoses looked suspect and since the system was already open now was the time to replace them. A pair of Dorman H96862 hoses were ordered on Amazon for $8.32/each and arrived in 2 days. Installation was straight forward but I did have to heat up the ends of the old hoses to break the unions loose. The diff, half-shafts, and everything else was re-installed. A few rounds of brake bleeding commenced and with a firm pedal achieved the rear wheels went back on and the car lowered back on to the ground. The initial impression of the rear spring change was good but only a test drive would tell.

-

Next up was the struts. With the half-shafts removed and brake hose disconnected it was just a matter of dropping it down and swinging it out. No surprise, the strut cartridge was shot. When it came time to remove it, no surprise that it was stuck in place. No surprise = No problem. I needed to make a handle of some sort to pull it out. Using a piece of scrap angled steel I drilled a hole in the middle, bolted it to the the strut and with a few hits of the mini sledge on the bottom it happily saw things my way. I had some Tokico struts and springs for a 280z that a fellow Z owner traded me for lunch at Torchy's Tacos. I already had some correct KYB rear strut cartridges but compared the rear springs and figured I would give them a shot. They are about 3/4 of a coil longer than the ST springs that were on the car. If this did not work I also had some 280z rear strut mounts that I could try as well. The ST springs did not have to be compressed to remove them but I did have to compress the Tokico springs a little which to me was a good sign. Reassembly was straight forward with no drama. The driver side received the same treatment as its strut cartridge was dead as well.

-

While the paint was drying I set about installing the RT mount. With the diff out of the way it was the easiest project so far. This is my 3rd time installing one of these so I was going to use the same "sandwich" recipe as before. Cutting one layer of the snubber mount off and retaining the original lower mount. You do have to use some longer bolts to get the lower mounting bracket started but the factory bolts can be used once you have it drawn up and into place.

-

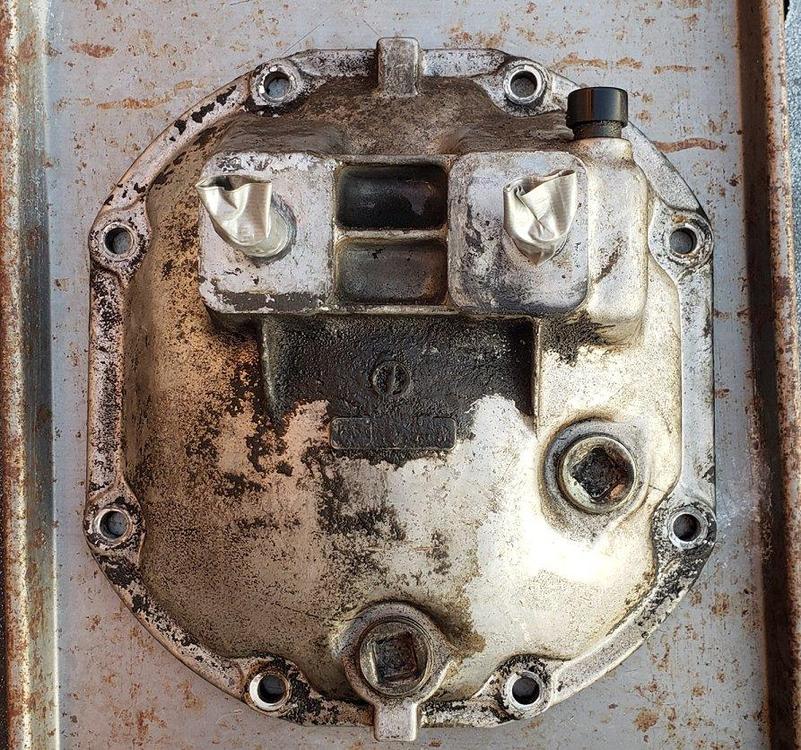

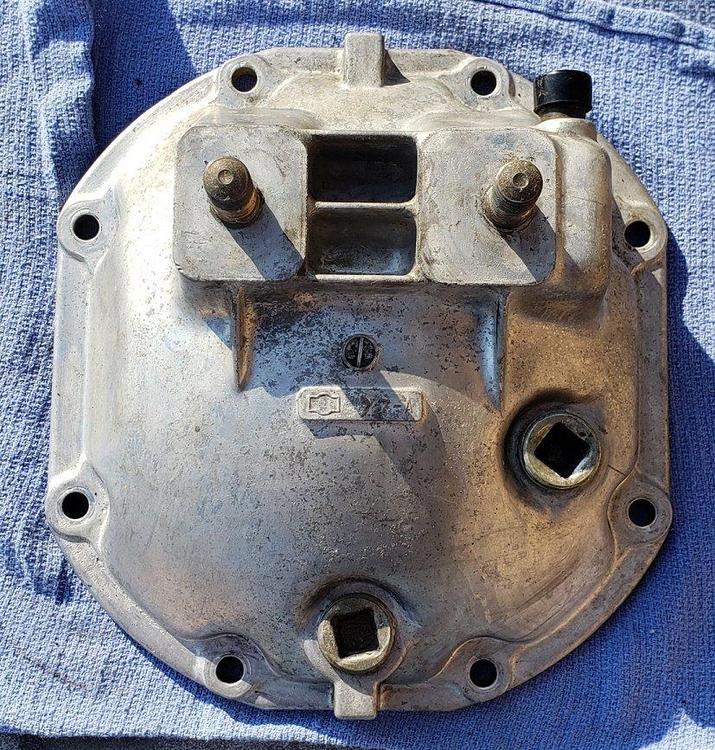

With everything checked out I spent some time cleaning everything up and painting it. A fresh cover gasket was installed with a light smear of black RTV. I used Red Line fluid that is designed for use in LSD differentials. Been using Red Line for years with nothing but great results.

-

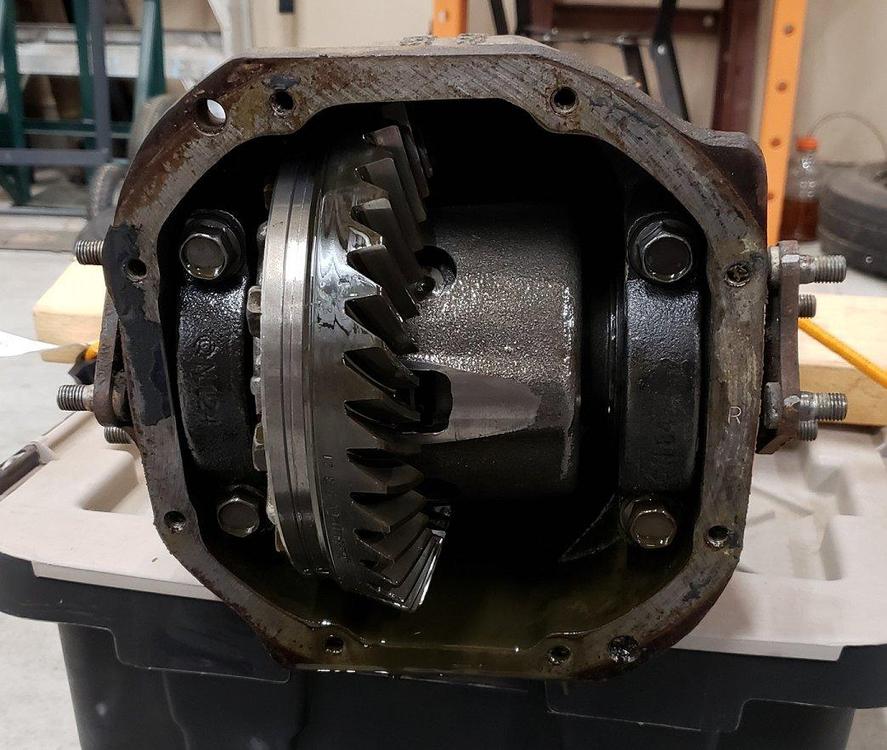

A few weekends ago I got back on the Z as I wanted to address some items before the ideal Fall driving season arrived. It is unknown when the diff fluid had been changed so I wanted to change it. However, due to the placement of the ST sway bar bracket it would require dropping the diff to do so. This actually worked in my favor as I wanted to replace the strap type upper diff mount with an RT mount I had on the shelf and see what could be done about the sagging rear suspension. First things first, getting the diff out. After about an hour or so of wrench turning and some assistance from wife it was out and safely on the ground. It was not leaking and a quick removal of the fill plug revealed it was full. I drained it and looked the gears over. Its an R200 with a Precision LDS and 3.54 gears. There was also no material found stuck to the magnetic drain plug. Moving forward.

-

If you are really going to drive and enjoy the car, you can keep it on if everything is in good shape but if there are issues with the system, everything can be removed and kept for a future owner. Take lots of pictures and label everything as you remove it. You mentioned you goal is to keep it as original as possible for value purposes. From a value stand point, I don't think you lose anything by removing it and keeping everything. Of course if you are going for concourse level shows, the system needs to be 100% intact and working properly. I had car #8011 and all of the smog equipment was gone when I got the car and when I sold it I do not feel anything was lost by not having it. A future owner will always view at least having in a box as a "nice to have" but probably not a deal breaker as series-1 cars continue to appreciate.

- 14 replies

-

- pollution control

- refresh

-

(and 1 more)

Tagged with:

-

I will add my experience to conversation so others are aware. Back in March I sold my 1988 Mercedes Benz 560SEC on BAT. I had already taken a lot of pictures and made videos based on my review other successful auctions. When I submitted my info I asked for a reserve of $10K and they accepted it from the beginning. I think it only took them a day or two to assign an auction team member to me. We did two rounds of reviews for the text and they accommodated my go-live date since I suddenly had to go out of town and wanted to be available to answer questions during the auction. The reserve was met and the buyer turned out to be a fellow MB owner and was familiar with the W126 cars. He chose to pay via a bank wire transfer and had the car picked up by a transporter a few days later. Once he paid I over-nighted the title to him. It went to Jamestown NY and I have not heard anything from the seller so I assume he is happy. Overall I had a good experience with BAT and would recommend it as long as you know what you need to do as a seller and to properly set your expectations. https://bringatrailer.com/listing/1988-mercedes-benz-560sec-12/ The big thing you have to keep in mind is, BAT is in the business to SELL vehicles and related parts. They know their buyer demographic, what sells, what doesn't, and what people click on. They want to create the highest probability a car or part will sell so that is why they come back with low reserves or no reserves. My brother went through this with his supercharged Acura coupe. They did not want any type of reserve and will not speak to him on setting one.

-

In an effort to make the interior a little nicer, I ordered a real leather shift boot and parking brake boot off of Ebay. For $35 I was happy enough. Its meant for a stock shift setup but with the 280ZXT T5 transmission and Hurst Mustang 5.0 shifter, the shifter sits forward of its original location so the leather boot demonstrates the compromise. One day I will have a custom one made that looks more correct but for now, its much nicer to look at and still smells good!

-

Been pretty busy since my last post. I started driving the car more to help dial in the steering. Luckily I am able to park the car on the center cover of my lift to make adjustments quickly with the weight of the car on the wheels. As I drove the car it seemed to idle higher and higher and that is when I discovered the I had some air leaks at seals between the carbs and the intake. In an effort to remedy this I had gotten the carbs out of sync so it was time to start fresh. I got carbs tightened down and all the air leaks stopped. As I set out to start re-syncing the carbs the car would not stay running once the engine started. I verified this as I was getting a full 12V at the key start position but nothing at the run position. I spent the better part of a weekend tracking down the issue which turned out to be the 12V wire going from the resistor to the coil. Simply moving the wire around seemed to fix the issue but I am sure I was knocking some corrosion loose. I have not doubt the issue will return in the future but for now it was running again. Back to my original plan of syncing the carbs which was very straight forward. Now the car consistently idles at 900rpm, set to 9 degrees BTDC, and runs much better overall. In the video below I still have an occasional pop on cylinder #4 which was remedied with a half turn of the mixture screw.

-

@ZCarFever The clips are now available for $30/set from Zeddsaver. He bought one of my sets and I am glad to see he is producing them and able to offer a better price. I recommend you check him out and purchase a set from him. https://www.zeddsaver.com/collections/miscellaneous-parts/products/datsun-240z-series-1-hatch-vent-clips-1

-

Been working this morning to get my carbs tuned. The engine is a 2.9L with a Isky stage-2 cam, Dellorto DHLA40 carbs, Mallory Uni-Lite electronic distributor, using an adjustable timing light and external tach to tune. Fuel press. set at 2.9 PSI. Base timing set at 10 degrees BTDC, any lower and the car idles rough. Idle is set to 1k RPM. Would like to get it down to 800 RPM if possible. Car seems to run very strong in the higher RPM range. Symptoms - while at idle the middle and rear carb will occasionally cough/pop. This happens more on the front throat of the rear carb. While driving, I can feel the transition from the idle circuit to the main circuit, like the car suddenly gains extra power. What I have done - from what I understand the transition from the idle to main circuit should be smooth and not jumpy. Since I was experiencing the carb cough I figured I needed to move my idle jets up so I went from 70 to 75. This seems to have smoothed the transition from idle to main and so far no carb coughing. However, it is now running very rich and is certainly noticeable. I have tried to lean the fuel mixture using the mixture screws but this makes the idle rough. Questions - At this point I am thinking I going back to the 70 idle jets and see if I can richen up just the two carb throats that were lean. If this does not work, is it a bad idea to run high idle jets in just these two throats? Just how smooth should the transition be from the idle circuit to the main circuit? I could certainly live with the way it was with no complaints. Once I make the changes above I will record the spark plug number I am using along with some pictures of the plugs after some high RPM runs.

-

Thank you Philip! The car could definitely use a cut and buff. One day I will focus more on the cosmetics but for now, I just want to get the mechanical systems up to scratch.

-

After the final align & drive session I made a quick video to show the progress and current state of the car. Still need to do some carb tuning as I am getting some inconsistent spitting and popping but it does run and if you lay down the accelerator in second, it absolutely screams. I plan to work on the carbs throughout the week as time allows. The next big project is raising the rear a little using some 280z strut insulators, install the RT mount I have, and change the gear oil in the diff. Stay tuned!

-

On my drive out to the exhaust shop and back I noticed the car was not tracking straight. This is due to the rack being moved when I was installing the new rack bushings. The car needed its rack boots replaced and I already new ones along with new outer tie rods waiting for me in the parts bin. I used Empi 88-1509K boots and Moog ES2109R and ES2110R outer tie rods just like I have used in the past with the same success. I also installed a pair of MSA aluminum bump steer/kick back spacers since I already had them. Took about a full 1.5 days worth of work but I spread it out over two weekend as I painted the outer tie rods with satin black Rustoleum to keep them looking decent. The locking nuts that come with the new outer tie rods are thicker than the originals. Based upon the measurements I took during tear down, the passenger side tie rods needed to be as close to the rack as possible and thus I needed to use a thinner nut. In the end, I could have used the new ones after adjusting everything but wanted to point this out. Using the center cover of my lift as a ramp I was able to quickly do several rounds of adjust & drive to get the alignment really close. I will be buying new tires in the future and will wait to drop $80 on an alignment. The list gets a little shorter!

-

Last weekend I ran the car up to Taylor Muffler to the get header collector welded to the existing pipe. Its a small Mom-n-Pop shop but they do good work for all budgets. After about 15 minutes and a $20 bill later I was headed back home. In 5th gear while cruising the drone is pretty bad so I will probably be back to get a resonator installed at some point. With the car running and driving again this officially wraps up the timing chain project I started on July 22nd 2018. Like all of our cars, as soon as you finish one project, another is waiting for you.