Everything posted by grannyknot

-

Dave W 1971/240Z rebuild

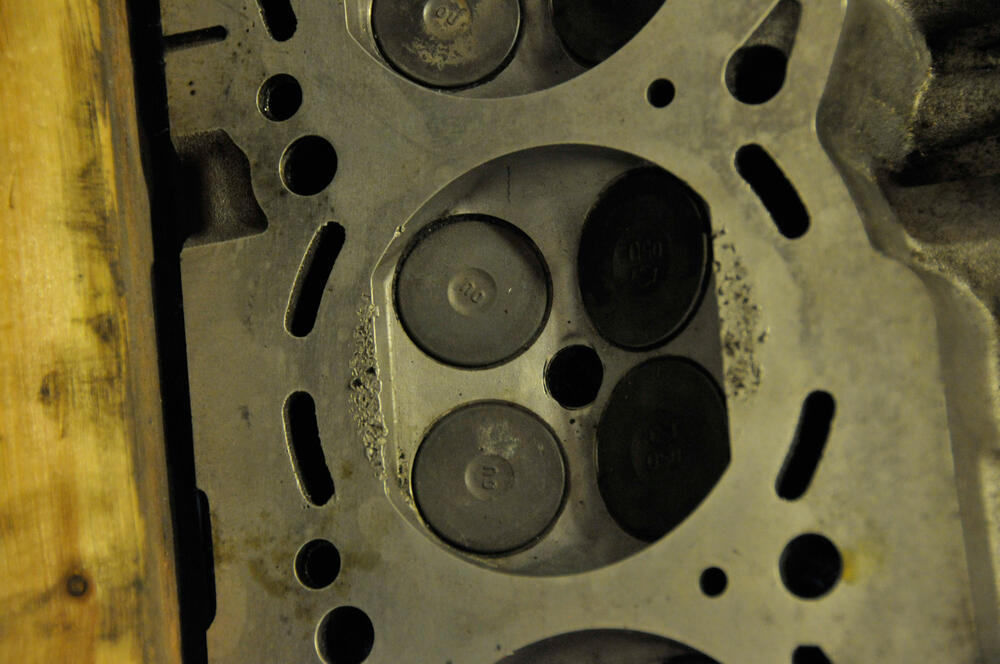

Right😒 soft bronze valve seats with unleaded gas, not a good combination. I forgot about those, so since the seats and valves have to be replaced anyway then we might as well go for the larger L28 valves and let this E31 head breath properly. Thanks for catching that @madkaw Off the top of my head I can't remember if installing the larger valves will affect the compression ratio, anyone? I believe the E31 head is already at 9.5:1 now and I don't want to go much higher than that. Damn, I spent several hrs yesterday reinstalling the valves, springs and cam yesterday and now I have to take it apart again, but better me than the machinist, I work a lot cheaper than he does😁 Dave, I will get a firm quote from him before I go ahead.

-

Dave W 1971/240Z rebuild

There is lots of stuff I'd like to do.😀 The valves are in good shape and so are the guides, also Dave would like to avoid mission creep, he is looking for a weekend driver that is as close to stock as is cost effective, gotta stay in budget.

-

Dave W 1971/240Z rebuild

-

2,070 mile trip in the new Z. Midwest to the West Coast. No Interstates!

Utah is a beautiful state, we go back again and again.

-

1973 240z Custom Wiring From Scratch

An electric fan comes on only when needed, mechanical fan is robbing power from the engine all the time regardless of whether it's needed. With the E fan off, as in hwy driving and the M fan has been removed, there is more power available to the rear wheels, not much more but some.

-

Dave W 1971/240Z rebuild

Oh that's right, I have the keys to the car in my possession, maybe I should have a copy made ... just in case.

-

Replacement Windshield Options

Jim, you clever bugger, I love that cord in the tube idea and the corn starch, I'm going to try both next time.

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

They were older carbs, some of the first produced, I had 40mm chokes as that's what worked out as the best all around for performance and driveability. It's been a few years now since I played with them so I'm a little foggy but I believe they will take weber jets. Much easier to adjust float levels and change jets as everything is accessible from the top of the carb, you don't have to take the take the lid off like webers. They are a superior design and if your mechanic can tune webers he won't have a problem with OER's, it is the same basic design.

- 240ZBUILTBYME 1971 240z HS-001063 Project Georgia

-

Dave W 1971/240Z rebuild

It's a trick I've heard about but never got around to trying before, it didn't take 2 min to do, no good on a cast iron block of course.

-

Replacement Windshield Options

I remove and install windshields exactly as you describe except now I use 3mm string trimmer (weed wacker) filament line instead of cord, I would never go back. The filament slides over the lip and rubber seal very easily with hardly any resistance which is especially good rounding the corners.

-

Dave W 1971/240Z rebuild

The second pic down I've welded a blob on top of the broken stud, 3rd pic I rest a nut on top of the blob and weld those together, quench it with WD40 and unscrew it. Most of the work is done by the heat.

-

Dave W 1971/240Z rebuild

After having saved some of the budget on the crank, I thought I would have a go at the broken exhaust studs, ah a few more dollars saved! Also got some painting done today and added some bling to the engine block.

-

Dave W 1971/240Z rebuild

I really don't like dropping off a crankshaft to be polished, very few machinists do it in house anymore so they job it out to a 3rd party that doesn't deal with the public. Once they have it, it can sit on their floor for months before they get to it. So I thought I would have a go at it myself, I started with 1500 wet/dry paper, lots of WD40 and an old shoelace. Spent about 2 min per journal, then cleaned it off and made a long strip of an old T shirt and some Autosol polish, about 1 min per and I'm done.

-

Dave W 1971/240Z rebuild

But even with all the trash that scored up the bearings, the oil pump is in very nice shape. As far as I can tell, the engine has seen light use but a lot of neglect, I'll bet most of that wear happened on startup with old dirty oil. I rolled the block outside yesterday, removed the plug sealing the main oil passage and scrubbed every hole with bottle brushes, lots of oil sludge in those lines. 💡 Could have been an obstruction in the line leading to oil starvation!

-

Dave W 1971/240Z rebuild

Well not a moment too soon for the bearings, at least they did their job and sacrificed themselves because the crank journals aren't that bad. I'll still send the crank out for polishing. Because the engine has been sitting for so long I gave each shell a couple of swipes with a scotch pad to bring out how much much copper is showing, these could have spun any moment. First pic is the rod bearings, second are the mains. The crank is showing some water marks and some copper transfer. Knocked out the freeze plugs and found lots of crud and silicone sealer clogging up passages.

-

Dave W 1971/240Z rebuild

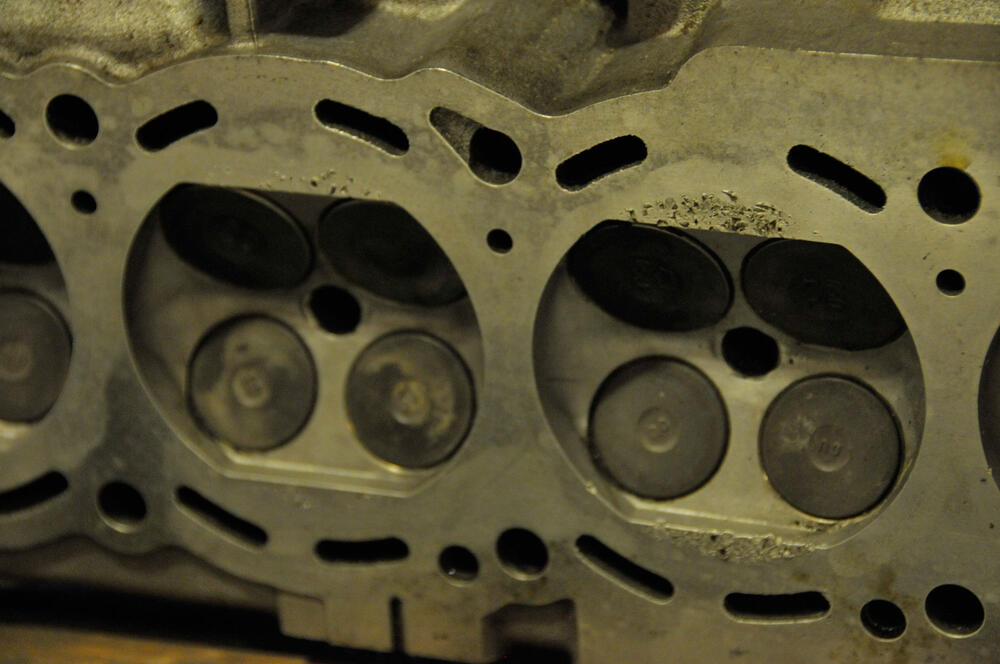

All the valves are out and clean, they are in very good shape, this the worst exhaust valve seat and I think I can lap that little bit of roughness out. I will take the head to my local machinist and have his skim the surface and remove a couple of broken studs for the exhaust manifold, I'm sure you all know which ones I'm taking about, either end of the manifold. Once I get it back I'll drill and tap those holes to M10. I big box of goodies from Rockauto showed up today.

-

Radio Faceplate Restoration Guide

Doh! Sorry, I'm looking at that faceplate and it clearly says tune but I'm thinking it is the antenna toggle switch from the earliest faceplates for the series 1.

-

Radio Faceplate Restoration Guide

A PO must have installed the early radio and face plate, have a look on ebay what those early radio & faceplates are going for, you could install an entire sound system for what they are worth.

-

Radio Faceplate Restoration Guide

You might get away with it but Landau black is pretty tough stuff all by itself. A77/280Z? That face plate is from one of the very early cars.

-

Dave W 1971/240Z rebuild

-

Dave W 1971/240Z rebuild

I hear you, that's why I had such a hard time believing it was detonation but I went back through some of my pics of other engines that had a foreign object bouncing around and there is always a recognizable shape of the object imprinted repeatedly. Also, in this case the top edge of the craters is raised above the surface like an explosion whereas a nut or screw just makes an indentation with a very little edge. A heavy wire wheel is a great thing but I try to do passive cleaning as much as I can these days, you end up with less crap in the air. Now I stand the valves up in a bucket with enough industrial cleaner ( Lye - Sodium Hydroxide) to cover the deposits and leave them over night, the next day you can wipe most of it off with an old rag.

-

Dave W 1971/240Z rebuild

@Zed Head, you are absolutely right, good call. I always thought detonation also need a relatively high compression ratio in addition to a lean condition, lesson learned. A friend just sent me some pics of his RB26 head and it is pretty convincing. Now I have to remove the peaks and try to smooth it out.

-

Dave W 1971/240Z rebuild

Lash measurements before disassembly, I've never knowingly seen detonation marks but seen lots of marks from nuts and screws and when one of those get into the cylinder both the piston and head are just hammered with marks equally all over both surfaces. I've never seen marks on either side like they are in this engine. None of the other cylinders have these marks, just #4 This is the exhaust valve and seat for cyl #1 with 160psi, the next 2 pics down are valve and seat from cyl #2 with 100psi On the #2 those crusty bits are hardened carbon that I had to scrape off with dental pick, I'm pretty sure that is the cause of the low compression.

-

Air Cleaner Manifold Hose

Even with the Summer/Winter lever turned to Summer, the hot air from the exhaust manifold will be heating up the airbox, best to leave the hose off but have it on hand for the next guy.