Everything posted by EuroDat

-

280z - Rear Bumper Term and Door Bumper Advice

I used a simple drill bit, but didn't go all the way through. Rolled the drill around while drilling to mill the spot weld away. Then pushing the sight shield up and down until it broke loose. No photos of that, but I do have some photos of the front 280Z turn signal brackets.

-

280z - Rear Bumper Term and Door Bumper Advice

Those support tabs on the sight shield have three and one tab even had four not so evenly spaced spot welds. I managed to remove mine without too much damage too it. I took some photos of mine a while back to help someone with removing the shield. Another interesting thing about the mounting of this shield is the dimples in the valance on the body. You can see their mark on the photo 2214. They are about 20mm in diameter and 2mm high. Located at every spot weld.

-

What's the most needed Z part that's currently NLA?

I know this is essentually focused on the 240z, but a part that is becoming extreemly hard to fine in any condition is the 280Z bumper ends July 1976 onwards. Front right being the hardest to find 62850-N4700 and left side 62851-N4700. Right rear bumper end 85350-N4700 and left 85351-N4700

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Hi Joost, The difference between the models 280Z is Non-California model distributors up to July 76: Manual, D6F4-01, dual pickups. Auto, D6F4-02, dual pickups, same as 01, but has a different vacuum advance pot. There is a 6 degree phase difference between the pickups that is activated by a temperature switch. California model distributor: Manual & Auto use the D6F4-03, both with a single pickup. When the temperature switch activates the TIU changes from one pickup to the other to retard or advance the timing. If you use this distributor with the HEI module, then connect the red and brown or brown and green. The brown is the common wire between the two pickups. Connecting the red and green to the HEI will give you a dubble wave 6 degrees apart. After July 76 they all used the single pickup distributor and matching TIU. The 78 model uses a connector plug in the TIU and a 12 volt coil, no ballast resistor. I'm not sure what the resistor value is in the 78 tacho. Being a 12volt coil, it could have a higher resistance.

-

Found 2 240Z's

Congrats, looks like a bargin. All depends what youwant to do about the seats. If you want to keep it original then you will ned to know the build date to fine the right seats. I wonder what the insurance company will consider as "cover". If you want originality, that can cost a lot. This site has a lot of options and if you call them, they should be able to help you. https://zcarsource.com/datsun-240z-parts/datsun-240z-interior-parts/240z-seats-upholstery/ A call out here in the wanted sections could find you a member wanting to part with a set.

- L20b Cody's Goon

- L20b Cody's Goon

-

A-Type 4 Speed Mounting Position Help!

Sounds like the guy was focussing on getting the job done, but mist bracing the tranny cross member and positioned the rails too far back. It certainly left you with some insteresting challenges. That is neat work on solving the transmission mount. You could shorten the drive shaft and use adjustable tc rods. Have you tried the steering rod to the rack and pinion. Going by all the other problems it will be the next.

-

Zx 5 speed rebuild

They are the ratios for the 79 to 6-80 280ZX coupe early close ratio 5 speed. Strange thing is the photos in your first post show the tell tale signs of a wide ratio. I was under the belief that the early close ratio boxes had the brass synchro. This project could shed a lot of light on this fairly rare transmission.

-

Zx 5 speed rebuild

Looking at the photo more closely, it looks like the bottom of the punch mark is protuding into the shaft. I can't remember every seeing a indent other than the notch. If there is a indent you would expect it to be exactly 180 degrees to the notch. Otherwise it would be difficult to locate where to punch it. The indent is not noticable outside the nut. I don't think it will be a problem. It's probably sheared off when it was removed the first time round.

-

Zx 5 speed rebuild

If you don't have something suitable, I would buy an el-cheapo screwdriver and grind it down to the same width as the groove and make the point more chissel like. With that you should be able to lift up the tab on the nut just enough so it won't tear when you unscrew it. They rearly damage the threads, but when the nut is hammered in like yours, you can tear that section out of the nut when you unscrew it. That is all you are trying to avoid with the screwdriver.

-

Zx 5 speed rebuild

Btw, That punch mark is the original nissan production method. The one that now holds the nut from turning is aftermarket rebuild.

-

Zx 5 speed rebuild

The punch spot is from a previous rebuild and not doing anything. The only spot you can lock the nut is where the groove is on the shaft. Someone has already reused the nut. I would rebuild the transmission and if the nut lines up where it is aready used, then take action the move it to new metal by facing the nut or adding and extra shim.

-

Zx 5 speed rebuild

-

Zx 5 speed rebuild

That is the correct nut for your main shaft. It is an M27x1.00mm right hand thread nut. It fits all the 5 speeds FS5W71B from 1977 to 1980. After 1980 the nut changed to left hand thread. I think that is when they also changed the 5th synchro. I think fibre synchro is right hand thread and brass synchro is left hand thread. You don't need to replace it. There is a trick to recover an old nut and safely reuse it. The section that is hammered down to lock it in place doesn't have any thread inside. It doesn't add any strength to the nut, just a way to lock it in place. Remove the nut using a small srewdriver or similar, you can drive it in between the nut and shaft to open it enough to remove it without too much damage. Side the nut over something like a socket in a bench vice and use a small hammer to peen around the burred section. You want to get it to point where it doesn't bind too much when you screw it on. When you rebuild the transmission and fit the nut. Tighten the nut and check where the burred section lines up. It probably won't line up with the groove, but if it does then have the face contacting the gear hub washer machined 0.5mm. This will turn the nut 180 degrees to the groove. Every 0.25mm will move the nut 90 degrees around the shaft, 1mm being the pitch. You can do this with the overdrive nut as well.

-

Shifter Lever Bushing P/N ??

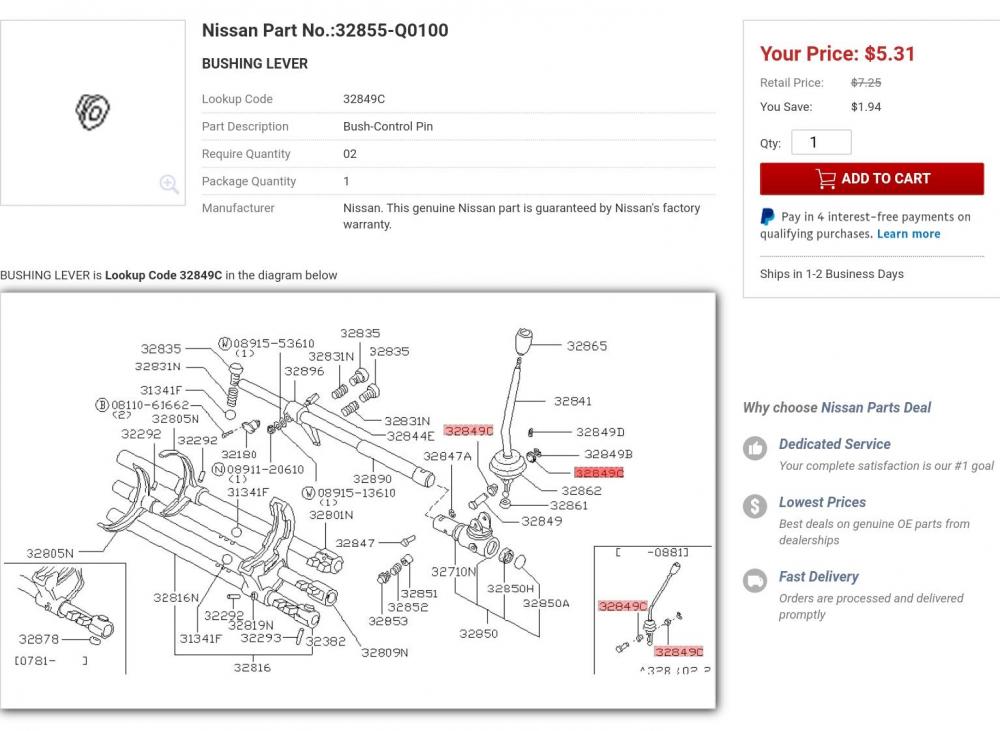

Checking that part number in the nissan part catalog. It comes up available, but they use the old 280Z diagram to show it. Makes it a little confusing.

-

Shifter Lever Bushing P/N ??

Thinking back a long time ago. Diahatsu Rocky transmissions had something similar in a couple of their transmissions. It was to eliminate rattles in the worn busses. The spring would always create tension on the bus/pin. That way it would not chatter when the diesel engine went through certain revs. This could be Nissans solution to that. Could be. It is not mentioned in anymanual and all the 280ZX parts list don't seem to show it either.

-

Shifter Lever Bushing P/N ??

https://www.nissanpartsdeal.com/1983-nissan-280zx-parts.html

-

Shifter Lever Bushing P/N ??

I'm glad you could follow that second last post. I was busy with another problem and lost track of what I was writing about.

-

Shifter Lever Bushing P/N ??

Not me, but it looks a lot like Norm the guy I did my apprenticeship. He ran a transmission repair shop in the eighties. Mostly doing Borg warner 35 Auto transmissions, but we also had quite a few datsun transmissions, mostly from the 720 trucks from the coal mines.

-

Shifter Lever Bushing P/N ??

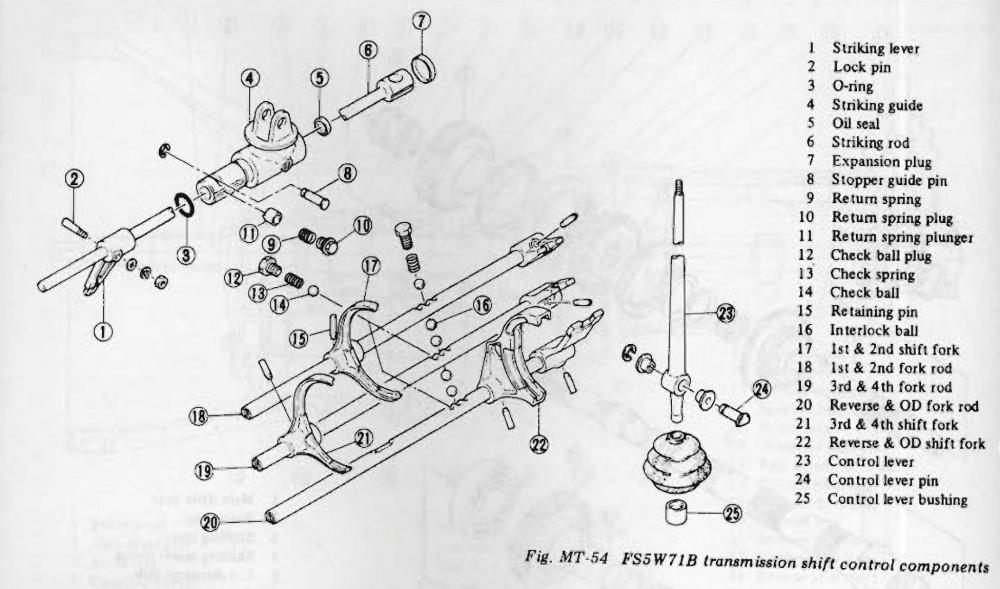

Hi Siteunseen, I have read that information as well, but it is not the reason for the design change/improvement. I have alsl read the the control lever bush Pos#25 moves through an arc when you go from 1st, 3rd or 5th back to 2nd, 4th or reverse. That means the bush would normally lift up out of the striking rod Pos#6. You would expect the spring to be on the bottom side to prevent this. Another thing I heard was to reduce vibrations transfering to your hand when changing gear. The theory is you press it in slightly and the lever floats on the spring. It's a theory. Creature comfort in the 280ZX.

-

Shifter Lever Bushing P/N ??

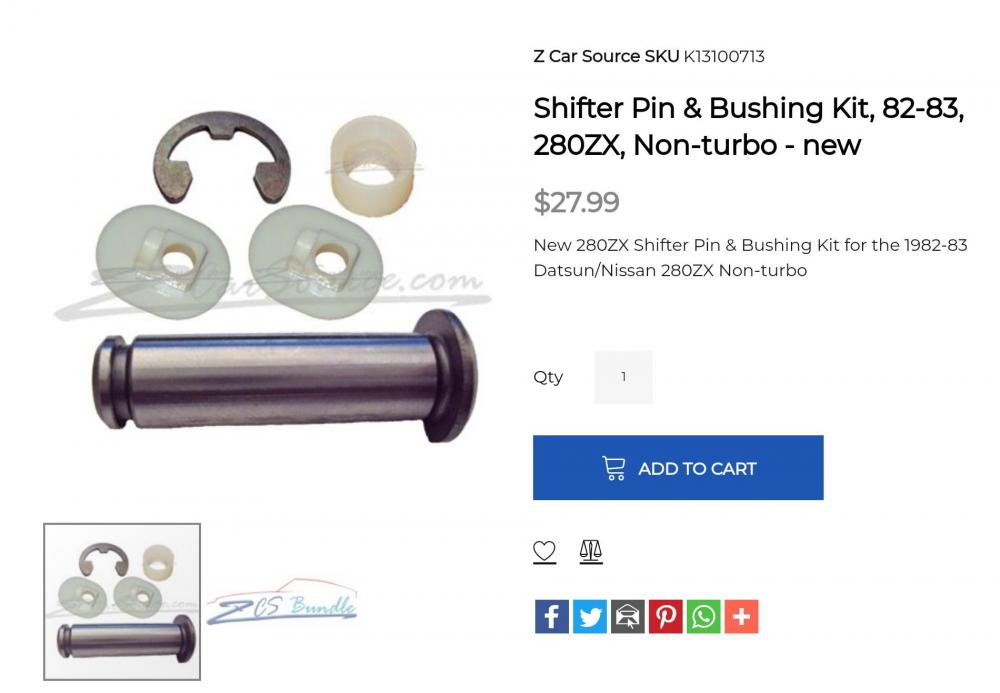

Zcarsource is the only site that still has them. https://zcarsource.com/shifter-pin-bushing-kit-82-83-280zx-non-turbo-new/ They have been NLA at Nissan for more than 10 years

-

Zx 5 speed rebuild

I agree. The only concern I have is the chipped teeth can crack further and (even though small) a chance the small pieces end up between the gears on there way down. Charles: You mentioned in another thread it has 23 teeth. I have only seen 21 and 22 teeth. Didn't know they were also with 23 teeth.

-

Zx 5 speed rebuild

Its not. The porsche type synchros are steel and this one is a fibre type clutch synchro. I think they changed somewhere in the 79-80 model 280ZX. About the same time they dropped the 4 speed. Of course all close ratios have the 5th warner synchro, but the 2+2 variant still used the wide ratio FS5W71B. Btw. Very bad idea for a manufacturer to mix servo type (porsche) and warner type synchros in the same transmission. The brass rings require GL-4 and the steel servo type requires a GL-5 lubricant like the diff.

-

Zx 5 speed rebuild

Hi Charles, Looking at your photos, you have the earlier fibre synchro ring for 5th gear. That part number I quoted is for the later version 71B and 71C in the 300ZX. You will need the manual for the 280Z 1977. The manual for the 280ZX wide and close ratio has the later type synchro on 5th gear. The part number you will need for 5th gear synchro is P/N: 32361-20100, but it has been NLA for more than 15 years. If 5th didn't have any problems, you should be able to use it again. The original p/n for the 1st to 4th synchro was 32611-14600, but has long since been replaced by 32604-P0100.