Everything posted by EuroDat

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

Mine will hold more than 1.5bar pressure for a least 2 weeks. It took me a while to get it that far, but replacing the check valve on the fuel pump was my eureka moment.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

When you change multiple things and something goes wrong it will always be a challenge with fault finding. If this problem wasn't there when I started, I would be changing things back one at a time to try and locate the cause of the problem. The question is: Can you change back or are you past the point of return? You already swapped the TIU and tried other coils with no improvement so the problem doesn't seem to be related to those units. I'm interested in the Volvo IACV thingy. I probably should read through the other thread, but I'm feeling a little lazy so I'll just ask. How does the Volvo system know where the idle is? The timing light seems to indicate no issue with spark, but could it be interfering with the ECU and fuel management? I don't think your problem is fuel delivery. You can have a blockage in the injectors and that will cause fuel starvation. If it's a blockage in the fuel system, then it will be after the fuel guage.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

It's hard to believe a 125amp fuse blows by swapping the reluctor wires, but there must be some relation if that is the only change you made before the fuse blow. I had similar problems with not revving past 2500rpm. Mine would rev cleanly to 2500rpm and then sputter around 2500rpm. It wasn't a hunt, more erratic running. I'm doing this from memory, since it is some years back. Like you noticed, I accidently swapped the green and red wires on the HEI terminals when I quickly fittrd it for testing. When I changed them back, the promlem was gone. FUEL: I don't think you have problems with fuel flow. If that was the case, you would loose fuel pressure. Pressure and fuel are very much related. You can have pressure with a restricted line, but when the injectors open for more fuel, the supply (flow) can't keep up and the pressure will drop. If your pressure is stable, then your fuel delivery is good. These old ECU's don't read fuel pressure. Bosch (and Hitachi) solved this by creating a constant pressure differential over the injector tip and using a Fuel Pressure Regulator with vacuum assist. Remember fuel pressure will follow the to vacuum in the manifold so I think it will vary a little with this problem. If you add a vacuum gauge next to the fuel gauge, they should work in unison. IGNITION: If you are using a 12volt coil then the ballast is not helping. It will reduce the voltage to the coil and cranking voltage is already reduce due to the high current draw from the starter. That was the whole reason for the lower voltage coils. During starting they would bypass the resistor and the coil would get battery voltage to help starting. Do you know the history of the Volvo coil? Could it be failing? Do you have another coil to test and see if that reacts differently? I'm still trying to get my head around your 125amp fuse blowing. It can't be going through the HEI. Nothing in the HEI can handle such high current draw. It must be a high labouring starter drawing so much current, but what could be creating such a resistance/load on the starter? Pre-ignition or timing firing way to early. You would think it would cause backfire. The motor is turning? I hope I'm helping and not adding to your problems. Chas

-

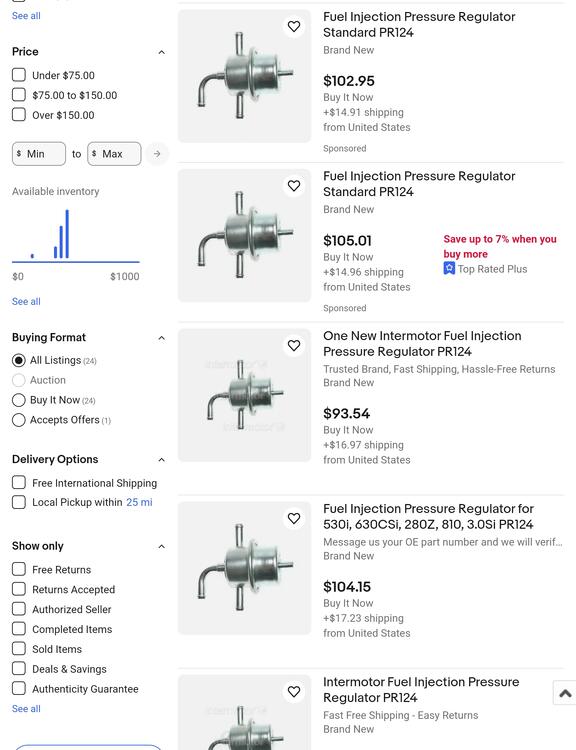

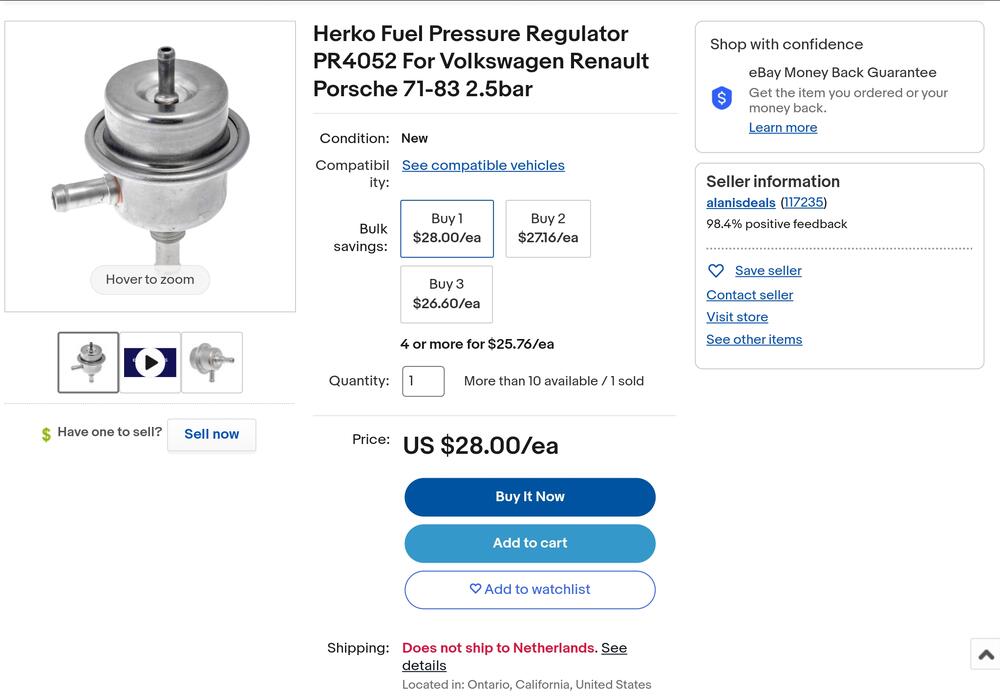

What is Everyone Doing for a Fuel Pressure Regulator?

Shouldn't you be looking for thr PR4052? The PR124 is the aftermarket for the 280Z 74-77. Both are 2.5bar spec.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Hi Zed Head, The wires were switched accidently during testing. I'll take a new photo and update the Tech sheet. Funny thing, looking through my photos and I can't find that photo anywher. Must have deleted it. Here is where my dyslexie kick in and it all when south for a moment..... I did start on the correct side and after running the engine which would not rev over 2500rpm, I corrected it and back on track.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Hi, I accidently swithed the wires when I quickly connected the TIU for a photo. I noticed it a year or two later, but funny no one else has made a note of it until now. The wiring for the HEI is correct. Trust me, when I was first testing it would not rev over 2500rpm. That was because I connected the two red - green wires on the TIU backwards Working from left to right, looking at the TIU with the wires coming out from under the TIU. B - Black wire: HEI Ground. Very important. BW - Black/White wire: HEI B (battery) BW - Black/White wire: Not used. L - Blue wire: HEI C (Coil trigger "-") R - Red wire: HEI W (reluctor input) G - Green wire: HEI G (reluctor input) You can set up the HEI next to the coil if you want. Just disconnect all the wires from the TIU. You can then use the power to the coil to HEI B and the HEI C terminal can connect to the coil negative. The blue wire on the coil negative will still need to be connected for the tacho to function. Make sure you ground the HEI well. PS: Agree with you on the terminal layout in the electrical schema. I try to find a terminal that is not full. Say it has 7 wires in a 8 pin plug, then I can figure out which direction I need to look at it.

-

Better Than Bondo??

-

Bosch (Volvo) Constant Idle System Instead of AAV & B.C.D.D

I havd been following this thread and a little suprised no one has commented yet. It is an interesting mod you're attempting and I hope it delivers the results you are looking for. Great detail and plenty of photos so others can follow. Slowly buy surely these parts (AAR for example) are getting harder to find and a possibld update to later more available parts is more than welcome.

-

Resurrecting my horn (the sans Viagra thread)

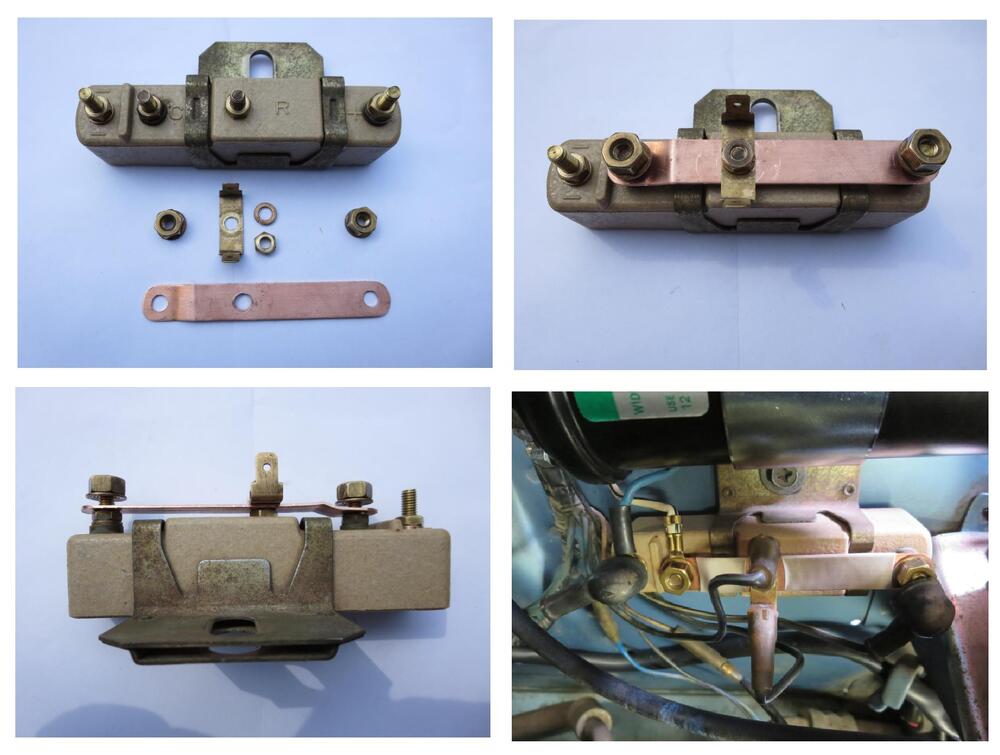

Yes the plated version is the 240Z version. The other one is a 280Z. I think there are 3 basic models of the S30 horns and probably more finer differences in the 3. The left horn in you photo is the later 280Z version. The single metal strip bolts to the bumper shock. The right horn is from the 240Z. There is also a variant on the 240Z version, I think it came in the 260Z and maybe the later 240Z. The have the same mounting bolt pattern as the 240Z, but the bracket connects to a single bolt on the back of the horn like the 280Z. See photo.

-

Stroker or turbo?

Let see, an engine in another Z, a couple of 280ZX turbo motors and a V07 crank lying around. You know they have therapy for that kind of behavior🤣 No real experience with either option, but I'm leaning towards the turbo camp. Turbo with an aftermarket MS ecu or similar to aid in tuning. I'm also quite happy to sit on the fence and watch this develop.

-

My two swiss S30Z Fairlady Restoration build thread

Ill have a look for the old one. I had one original still in good condition to copy from. If I can find it I can get some copies done, but it will take a couple of weeks because our machinist is on holiday, and we "untrained" engineers are not allowed to play in his workshop😁

-

My two swiss S30Z Fairlady Restoration build thread

Mine dit the same thing, and I DON'T drive it hard. Ended up making them out of HDPE from work. They have been in the car since 2014. The instructions look exactly like the ones I have in my map and I ordered them from MSA.

-

1977 280z EFI baseline settings

The variable resistor on the coolant temp circuit will richen your mixture. These old analog systems are known to lean out over time. Probably not what you are looking for to pas your emissions test, but it's fun to play with and I think it's the only form of tuning you have on these old efi systems even if it's just restoring original settings.

-

1976 280Z Fuel Issues Troubleshooting

Hi Paul, I would bypass the resistor or bridge it over if you are looking for the original look. I bridged mine in the photos. The condensor should not be an issue, it's more a noise supressor than anything else. Like Zed Head said. It could be a heat issue. You could try and mount the HEI module with the heat sink plate next to the coil. Then you have the shortest circuit to the coil and good grounds in the area. Once you know it works, then you can more to fitting the module in the original position. The HEI will get hot, and the flame thrower in no exception, but heat is not a good thing in these units. The high resistance the resisitor is generating will not let the HEI function as it was designed. Not helping. Btw: My TIU was overheating when failing. Like yours it would leave me stranded on the side of the road. A quick spray with very cold circuit cleaner would bring it back to life almost instantly. A passenger (my wife) could spray it and the engine would come back on after a second or two.

-

1976 280Z Fuel Issues Troubleshooting

Hi Paul, It's a pity you're having issues with the TIU mod. I ran mine from 2014 up to October last year with I had the good fortune to buy a 280ZX unit. A couple of suggestions. You are running a 0.3 ohm flamethrower coil with the resistor. That coil should have 12 volts, the HEI has a current limiting function to get the maximum out of the coil. The blue wire should go straight to the negative post on the coil, or via the end terminal on the resistor, if you want to keep the original look. Not mentioned in the instruction, but check the reluctor air gap. That is crucial for the HEI because the HEI needs 0.5 volts to trigger and too big a gap will quickly drop the cranking volfage to 0.3 volts. The other thing that can give you problems is the reluctor in the dizzy. If it is old and the insulation is starting the break up, it will not generate the voltage required to trigger the HEI. When you crank the engjne, it will generate 0.5 volts and will reach around 28 volts a high rpm. That high voltage can bridge poor insulation and cause your problem.

-

1977 280z EFI baseline settings

Agrëd. My 77 was leaking through nr 3, 4 and 5 injector seals and the dip stick seal was gone.

-

1977 280z EFI baseline settings

Hi sboy. Welcome to the club. Checking vacuum leaks, you could try what was called the yogurt cup test. The original thread "Purs like a kitten" is unfortunately long gone, but this one describes the procedure well enough. You basically block the afm and blow very low pressure air into the manifold and spraying soapy water on all the suspected areas. If it is tight and doesn't leak, you can move on. Zed head is right with the AFM. It's an hands off device, it's not tunable. In fact these old efi systems are not very turnable en this JECS variant of the Bosch L-jetronic does have some known issues with leaning out over time. Vacuum leaks and things like the AAR leaking air past the throttle body are your most likely issues. Mine 77 280Z was sucking air through the dip stick when I first got it. Changed hoses and even the injector seals before I found it with a simple yogurt cup test and soapy water.

- Oil Pressure Sending Unit Problems

-

75 280 Rear Suspension Work & Disc Brake Conversion (MilkFab)

The diff damper looks home made, but it is an original add on to reduce diff vibrations. Some people remove them thinking it is some kind of home made add on. Interesting photo. The cat has some kind of O2 sensor and an EGR take off. Do you know what is does or where the cable and piping go? The J-tronic didn't have O2 monitoring. The fuel hose is not suitable for EFI. Most stores try to sell you regular fuel hose, but these cars need high pressure fuel hose with a rating of 4 bar. The EFI runs at 2,5 bar, but the pump can deliver 4 bar. The floors look in great condition. You will know more when you clean it back to bare metal. I'm also a little amazed that the original exhaust shielding is still intact. Long time since I saw one with the shielding in such good condition.

-

My Datsun 240Z

Bart, Looking goed as always👍

-

Z's on BAT and other places collection

Yes, that it. It's the later 1978 onwards fuel pressure regulator. It serves no purpose on the pump. Without vacuum it will provide 2,5barg and you will still need exactly the same thing after the injectors to reduce the pressure to compensate for the vacuum in the manifold. Someone probably thought the pulsation damper looked like a regulator and replaced it with one. Could have just left it out all toegether. According to the bosch FI manual, the dampers main purpose was noise reduction more than anything else and this system is basically a bosch system.

-

FS5W71B Transmission Failure. How and Why

I wouldn't leave the ball out. If the washer gets the chance to spin it will weld itself to the main shaft, trust me☹ I remember a guy bringing in a seized tranny and the washer was friction welded to the main shaft, after he rebuild it himself. Our conclusion was the main nut was not torqued correctly. We had seen it in a couple of our rebuild transmissions where it became hard to use the gears and it still wanted to move forward in neutral. To make sure that didn't happen again, we torqued the nut with a homemade (workshop) tube socket that fitted over the length of the shaft. We tested it a couple of times by tightening the nut first by hand and then checking with the tube socket and torque wrench. It was then we found that by hand we were tightening the nuts to about 3/4 specified torque iirc. This is all going back to the eighties. The guy with the welded washer. The main shaft and fifth gear were a throw away, but for the rest of the transmission it was in goed condition.

-

N47 Head Exhaust Liners Question

If you use a P79 head on a standard N42 block that had a N42 or N47 head it will kill your CR and serverly reduce the performance. You can modify the P79 but shaving it 80 thou (2mm) use the valves from the N47 head (N42 & N47 vavles are two mm longer) and shim the cam towers. That will compensate for the 10.9cc dish in the pistons.

- L20b Cody's Goon

-

1976 280Z 2+2 - Wiring Diagram - Non-California

Hi LorenB667, Nice work and great that others can enjoy alll the effort you put in to it. You can upload wiring diagrams in the download section of this site. That would get for future use. https://www.classiczcars.com/files/category/1-wiring-diagrams/