Everything posted by EuroDat

-

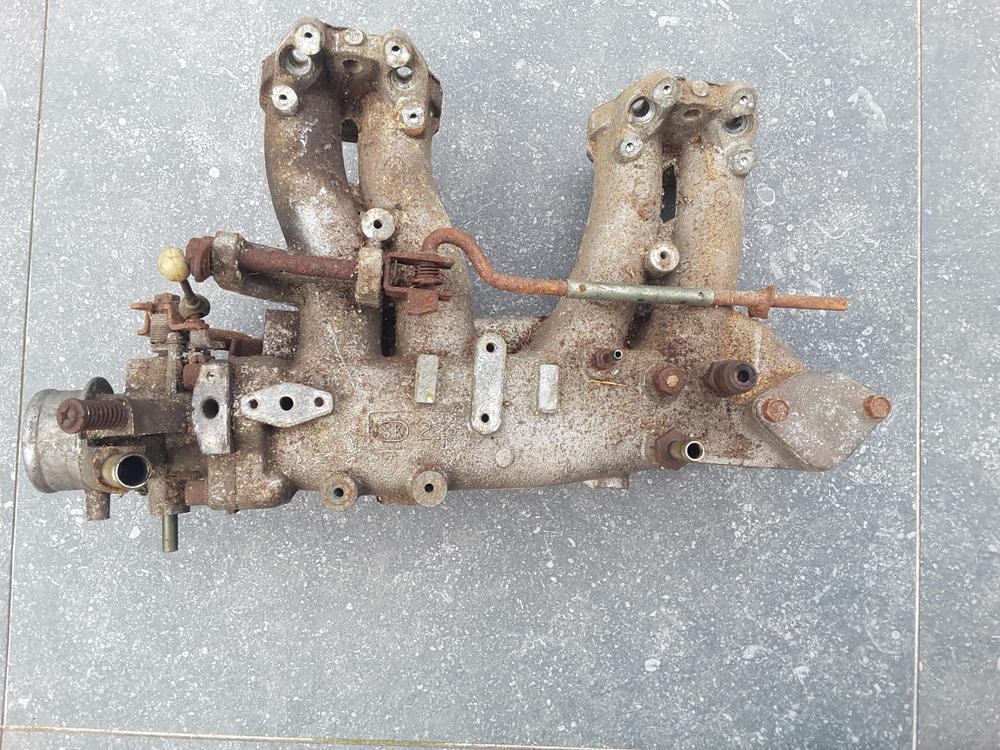

AFM/ Fuel Pump

I'm not sure I understand the upgrade. Isn't the ZX throttle body butterfly 50mm and smaller than the 280Z? It is certainly smaller for the rubber connection to the AFM. It would not be an upgrade. Could it be a 280ZX turbo? I don't know the burrerfly size in them, but expect them to be bigger. The common upgrade in the past was to use the early 240SX (JECS) 60mm throttle body on the early KA24E engine. It had the throttle body position switch in the same position as the 280Z & ZX. The 280ZX tb was an upgrade for the 180B guys with the L18 engine.

-

5 Speed Transmission inspection and possible rebuild.

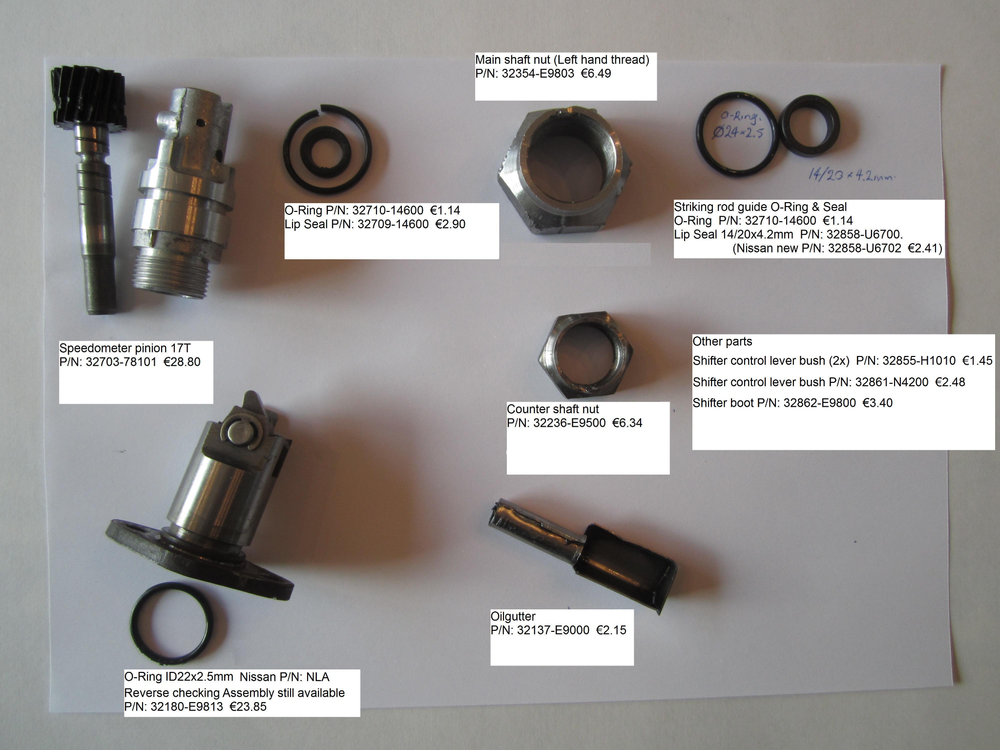

The seals I mean are for the striking rod guide. They are often forgotten during a rebuild. If the last rebuilder re-used the nuts, he probably didn't replace the small seals. Same goes for the speedo drive seals, but they are easy to change with the tranny in the car. See top right in photo.

-

5 Speed Transmission inspection and possible rebuild.

Yep, Seem is 12 o'clock. I can't find any photosof mine except a couple of the old ones on the bench. A good idea to fit it as one of the last things you do before putting it back together. Less risk of damging it. Do you have all the seals for the selectors? They are often a source of oil leaks and now they are easy to change.

-

5 Speed Transmission inspection and possible rebuild.

The edge of the socket is almost at right angles. I used it this way because it centered easier, but I understand your concern. It would work with the socket the other way around.

-

5 Speed Transmission inspection and possible rebuild.

I found it. It has a M10 threaded bar, but M12 will also pass through the socket. If you look at the wood, you can see the indentation from the extension housing. I added the socket to take a photo of the complete setup.

-

5 Speed Transmission inspection and possible rebuild.

Pretty much what you described. I used a 19mm socket with all my extensions (6" & 12") on the inside to stop the bolt from turning. I also had to cut a "C" section out of the wood to make room from the old bush to come out. I pulled the old one out with only warming the housing with a heat gun. Once it cracked loose, it slid out easy. The new bush was in the freezer overnight. Warmed the housing again to about 60 degrees C, rubbed a bit of oil in the housing and pulled the new bush in. Like Dave mentioned, check the slot for the oil lubrication lines up, otherwise the bush will have a very short life. I'll have a dig around in the garage. I think I still have the block of wood and threaded bar in the box of transmission bit and pieces.

-

5 Speed Transmission inspection and possible rebuild.

I pulled mine out and pulled the new bush back using the a "tool" I made. The "tools" I used: A block of 4x2 hardwood (not pine) with a hole drilled through it for a M12 bolt. 1" socket (outside diameter was 24mm) with 1/2" drive so M12 bolt would fit through it. M12 bolt 200mm long with full thread and nut and washers. Can also use thread rod with two nuts. Assembly: assemble the m12 bolt, washer and socket and insert through bush out the rear of extension housing. Fit the block of wood a washer and nut and tighten it until firm. Heat the housing until warm to touch. Start extracting bush by tightening bolt. It took me about 20 minutes to make it and replace the bush. You mentioned ordering the front and rear seal kit from zcardepot. Did you order the other seals from them. Speedo o-ring and lip seal, selector seals and reverse lock out o-ring. I don't see the selector seals and reverse lock out on their site, but you can buy them at any hydraulics supplier. It would be advisable to replace the shifter bushings. They have the original kit. https://zcardepot.com/collections/driveline/products/shifter-bushing-kit-oem-240z-260z-280z-280zx Some people use the brass bushes, but there are positives and negatives to using brass. Positive: It wears a lot less and doesn't require replacing as often. Negative: Brass requires lubrication and to reduce rear. Once they wear they can clatter due to small vibrations in the drive line. I prefer the originals, but that is my prefference.

-

5 Speed Transmission inspection and possible rebuild.

To check the play in that bush just use you propeller shaft (tailshaft for some poeple). Insert the yoke until the it lines up to where the seal was rubbing on the yoke. Generally recognisable by a shinny ring area around the yoke. That is important, if you push the yoke all the way in, the wear section will not line up with the bush. If it is on a new section where the bush wasn't rubbing, it will have less clearance and seem ok.

-

5 Speed Transmission inspection and possible rebuild.

Hi John, I was looking at my parts list and see I uploaded an old one. Back in 2012 I realised I forgot the input shaft seal. You should replace it as well. P/N: 32114-Y4000. Lip-Seal 30/45x8mm (NOK: AH1679G) I updated the list and clean it up a bit. It's also uploaded in the technical articles section. Tranny_Rebuild_Partslist-2020.pdf

-

FS5W71B & FS5W71C Rebuild parts list

- 96 downloads

- Version 1.0.0

This is a part list with all the main replacement components. Some components are no longer available through Nissan. The dimensions are given where possible so people can source aftermarket parts.Free -

5 Speed Transmission inspection and possible rebuild.

Yes, remove the rubber seals from the bearing. You can pop them out with a small screwdriver. Once it is out of the bearing you can grab it with pointy nosed pliers and twist it back and forth until it breaks and them pull it out. The rear yoke bearing (sleeve) doesn't look that good. You can check the play by insert the propeller shaft yoke and check clearance with a feeler guage. You can buy them. See my list for the part number. Nissan never did sell them. You had to buy the complete rear extension housing.

-

5 Speed Transmission inspection and possible rebuild.

Zed head has a good idea. Buying two oil gutter would be wise. They are delicate and easy to damage. I use to think the main shaft nut was ccw on all the close ratio 71b transmissions, but they seem to have a cw nut in the early close ratios up to June 1980. Chas

-

5 Speed Transmission inspection and possible rebuild.

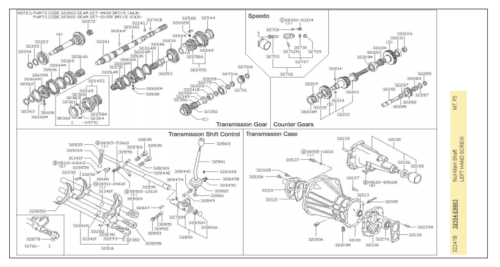

Bearing specs: C3 is a clearance spec, not a tolerance. The C3 clearance is regarded as the standard general use clearance and with accomidate most thermal expansion and load conditions under moderate rotation speeds. The oil gutter is used in all the 71B series transmissions. Still available through nissan, just google the part number in my list "nissan 32137-E9000" and yoh will find plenty of suppliers. Courtesy has them for $2.67ea https://www.courtesyparts.com/oem-parts/nissan-gutter-oil-32137e9000 The bearing in the adapter plate shouldn't has seals. I would remove the seals and flush the bearing with a degreaser and then fresh oil.

-

5 Speed Transmission inspection and possible rebuild.

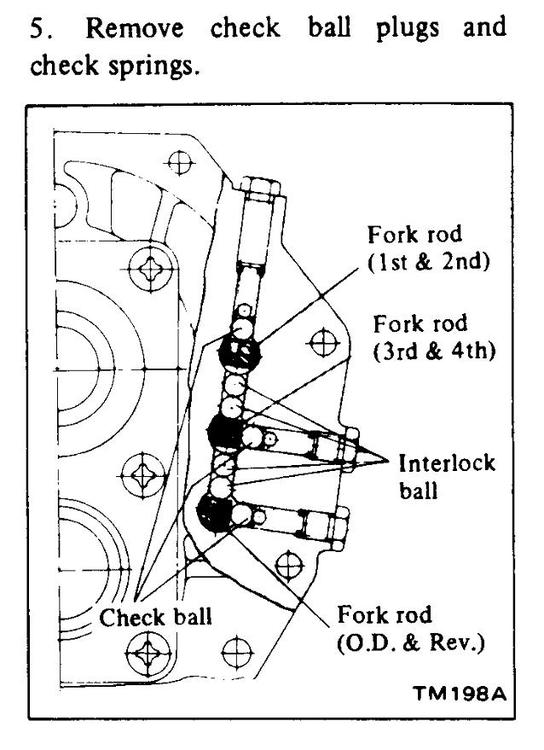

Visually it looks in good order and it looks like someone did the bearings in the past. Seals: If you buy aftermarket seals (o-rings and lip seals) remember to ask for NBR or Viton rubber. Sometimes they have EPDM. Check springs: I don't know if you can still get the check springs, but they do make a difference in the selsctor movement. My old ones were about 2mm shorter than the new ones and lost a lot of tension. They gave it that kind of click sensation when the shifter goes into the gear. If you can't get the springs, you can try a couple of small washers with the same outside diameter behind the old springs to increase the pressure. Be carefull not to go overboard or the springs could bind and loose function.

-

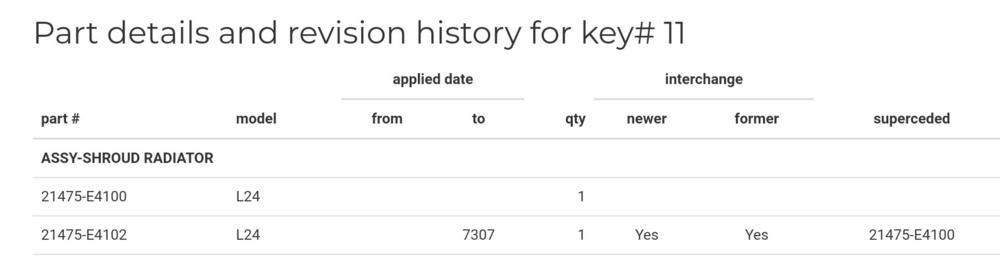

Unicorn Alert: 240Z Fan Shroud

@jfa.series1 Hi Jim. You quote a nissan part number for the metal shroud. I'm just curious because nissan quotes two part numbers for the 240Z. E4100 and later E4102. Could the E4100 be the metal and E4102 the more common plastic version. "Rare Nissan Fan Shroud for 240Z. This is P/N 21475-E4102, a fully reconditioned metal fan shroud to fit the OE radiator frame of a 240Z"

-

5 Speed Transmission inspection and possible rebuild.

Here is a list of the parts when I did the close ratio I had. The seals are what you want. The seals, springs and oil gutter are listed in their sections according to the parts manual cross section drawings. I think I will clean up that list and post it in the technical articles later. Tranny_Rebuild_FEB2012.pdf

-

5 Speed Transmission inspection and possible rebuild.

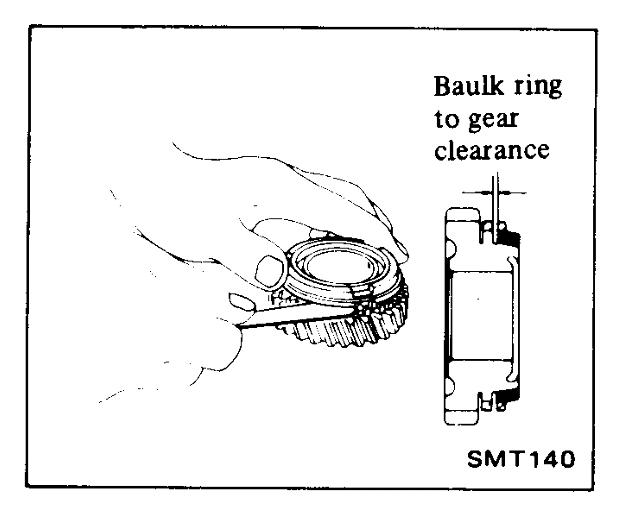

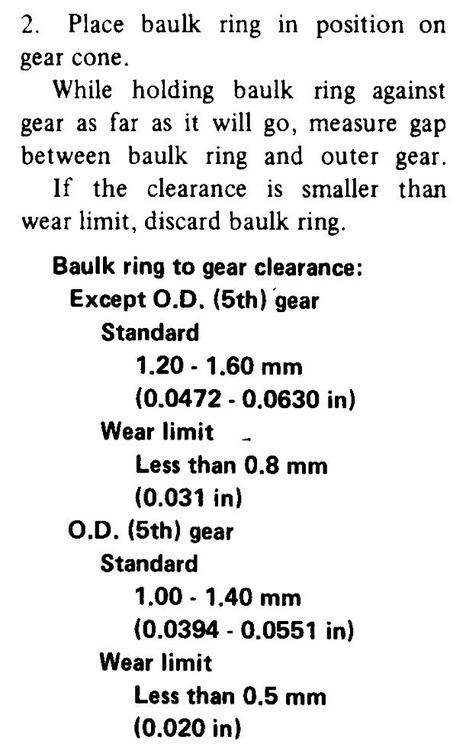

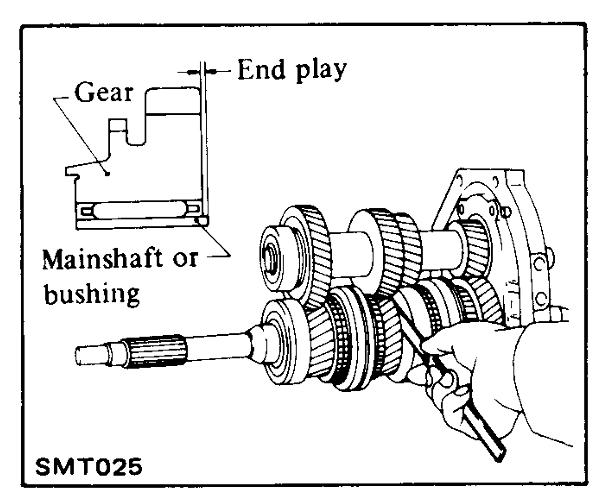

Looks like the bearing have been cheaply replaced. Why I say cheaply? They reused the nuts. I wonder if they changed any of the seal while they were at it. It looks very good from the video. Reverse gear is still in good condidtion (the idler spur gear), but that is generally due to the reverse lock out device helps prevent accidently hitting reverse on change down in the close ratio transmissions. You can take some measurements without striping it down any further. It will take a bit of fiddling, but it can be check without dismantling. That will give you a better idea of the condition. Baulk rings: The grooves inside the baulk ring do all the work getting the gears to similar speeds. The teeth on the outside of the baulk ring do the last step by aligning the teeth. It the grooves are worn down, the gears will be at different speeds and the teeeth will grind. That is the wear that Mark is talking about, but it started at the worn grooves. Gear end play: The next thing you can check is gear end play. If you are driving and take your foot the throttle and the transmission goes clunk. That can be other things like the diff, but it can also come from the gears snapping back. While you are in the transmission, I would put changing all the seals and the oil gutter ZH mentioned on my priority list. Those oil gutters can get damaged during rebuilds and can take so much benbing back before they break off. They only cost 3 or 4 dollars. I have a list of all the seals with Nissan part numbers and sizes so you can source them locally. The check springs in the selectors would be nice to change now.

-

5 Speed Transmission inspection and possible rebuild.

I just received a notification and while watching the video see you already found the reason while. The striking rod needs to move from left to right after the case comes away from the adaptor plate. Once you remove the reverse check lock out "thingy on the side" it will allow you to move the striking rod past the selectors and pul, the extension housing off. I generally use a large philips head screwdriver in the shifter to giggle it around past yhe 5th/Reverse position and them it will come free. Btw: The manual says to use a hammer to tap it off. What they mean is break it loose from the adaptor plate and extension house bearing.

-

Unicorn Alert: 240Z Fan Shroud

Yes, fan shouds seem to be an option and standard on the models with AC. Btw: @lonetreesteve Looking at the CL ad you posted That 72 240Z has the plastic shroud I think is P/N:21475-E4102

- 1976 280Z Restoration Project

-

Unicorn Alert: 240Z Fan Shroud

Steve, All the L26 and L28's had two piece plastic shrouds I'm not sure if the later 73 L24's had a plastic version. They could have. The part number changed about mid 73.

-

280z parts for sale

Looks like mostly 280ZX parts. @DatsunZGuy might be interested since he is currently restoring a 280ZX. The diff looks like someone transplanted a 300ZX turbo (84-89) diff into a 280ZX. If it is then it should be a 3.7:1 ratio clutcb type or the rare viscous type (1988 white SS edition). You would have to remove the cover the confirm whats inside. Someone could have simply swapped covers on a standard diff. Interesting transmission under the truck body. Is it also ouf of the 280ZX. That would make it a close ratio F5W71B. They are getting harder to find.

-

Would like to start a "One of these things is not like the other" forum group. Input?

I agree. If you master searching throught the carpartsmanual website or something like the e-fast database you will determine the timeline by the changing part numbers. The bennifit of this thread, which is not there yet, would be to provide a photo with the relivantpart number. For example Type 1 up to 73 p/n: 86550-N3400 no lever Type 1 up to 73 p/n: 87500-N3400 with lever etc

-

1978 5-speed transmission Tail-Housing Removal?

I think the monkey motion used two o-rings, but it is a really long time ago since I seen an A apart. All the o-rings and lip seals are still easy to find at any hydraulics shop. Just remember to ask for NBR or Fluorelastomer (Viton). Don't use EPDMwith mineral oil, that is used in the brake and clutch systems.

-

5 Speed Transmission inspection and possible rebuild.

I notice the difference in tone as well. Funny, I have an 82 close ratio and it has the same tones in the casting. It looks like they made the castings in two different factories, if that was possible. +1 for @siteunseen cleaning method and then open it up and have a look. You will be just guessing untill you crack it open and have a gander.