Everything posted by EuroDat

- 1976 280Z Restoration Project

-

New clutch...Noise when clutch is not depressed and trans in N?

Did you replace the throw out bearing or is it the original? Did you check if it turned freely before fitting the transmission? What you are describing sounds like a noisy throw out bearing. If it is what I think it is, you will know soon enough when you take it for a test drive. It will make the noise when you are driving it in all gears. If you depress the clutch pedal slightly and the noise goes away. It's the throw out bearing.

-

Parts Refurb

Amazing results. Time well spent and those inspection light housings look like new.

-

Project 280Z in Vegas

The way I removed mine. First remove bumper. I then drilled out the spotwelds on the four supports with a spotweld cutter. That made it possible to lift up the shield enough, it will deform a little and the drill out all the spotwelds along the top lip. You can see the holes I drilled in mine in the photos above. The valance panal has dimples (round sections that sticks out about 1 mm) where each spotweld is located. You will need to do some panel work to remove them or leave them, but they will be visable even with a 240Z bumper. I see if I have a photo of what I mean.

-

New clutch...Noise when clutch is not depressed and trans in N?

I take it that L28 is in a 280Z. Did you do anything to the slave cylinder? Change it for another unit? Reason for asking. The 280Z slave cylinder has a spring behind the piston. It has two functions: 1. Prevent free play in the mechanicals between slave clinder and throwout bearing. 2. Keep the throwout bearing on the pressure plate so it spins with the pressure plate and doesn't slip. If it slips, it generally squeals or makes a peeping noise that comes and goes. It is easy to test. The noise will disappear if you apply the clutch a little.

- Dieing issue

-

Project 280Z in Vegas

Dito with the welcome. Looks like a really nice find. My advice on the bumper swap. Be carefull and take your time removing the rear bumper gap shield. It is spot welded to the body and easy to destroy while removing it. If you decide later to restore it to original, you will need it. Mine is stored away for one of those "you never know" moments. 280Z's aren't the collectors items the 240Z's are, but as time goes on you never know. The collectability factor will depend on its originality.

-

Front Lower Control Arm Bolt..... Seized to inner part of bushing

Sounds like the bolt has rusted solid to the inner sleeve. They generally do, but your case is extreme. Reading your post, sounds like you have tried most things possible. Heat could help release it, but you can't get enough heat into the sleeve section. It will just dissipate into the control arm and burn the rubber in the process. I think your bolt is a gonna. You have a new bolt and rubber bush. I think your best option is cut through the bolt and sleeve on both sides of the control arm with a saw. Once it is out, heat the control arm and remove the rubber section with the remaing inner sleeve and bolt. Tip: I see a lot of people litterally burn out the rubber section. This creates a lot of toxic fumes and smoke. I heat the outside section until the heat penetrates through to the rubber and the rubber release. Grab the bushing with a pair of pliers or vice grips and keep trying to turn the bush while heating the outside. When it's hot enough it will release and slide out with a minimum of smoke and fumes. You can then push out or cut through the outer sleeve.

-

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Clearly an aussie accent???

-

How to fix your 260Z or 280Z clock

- 37 downloads

- Version 1.0.0

A number of people refer to this document for repairing the 280Z clock. The thread where it was originally posted is no longer available so I'm posting it here in the tech articles. This is where is should be. No credit on my part. That goes to E. Bettio for writing the article and Monkey Man for posting itFree -

Clock repair/restore

I couldn't find the thread either, but here is the document. I'll post in the tech articles as well. Like Ron said, all credit goes to E. Bettio. Nov 2013, looks like I have had it for a while How to fix your 260Z or 280Z clock - rev 1.pdf

-

want to put 240z bumpers on 280z

If I look at the design, the Skillard system does have an interesting approach at solving the vertical brackets being in the way of the 240Z grill bars. When I made mine, almost 8 years ago, there wasn't much out there and what was available was poor quality. Now there are several vendors making the brackets. Skillards design is different in the way that it does give you the opportunity to fit the 240Z grill or their Skillad grill. I like their out of the box thinking, but I do wonder how much flex the horizontal brackets will have?

-

Thinking about installing an BMW M6 engine in my Z

For a fleeting moment I thought, "could the disc be backwards", but then I thought, No Chris wouldn't do that. Looking at the photos I can understand why it happened. That is not playing by the rules of common sense. Bad move on the manufactures part. It's not even a special letter type, just a standard F.

-

Won't go into gear

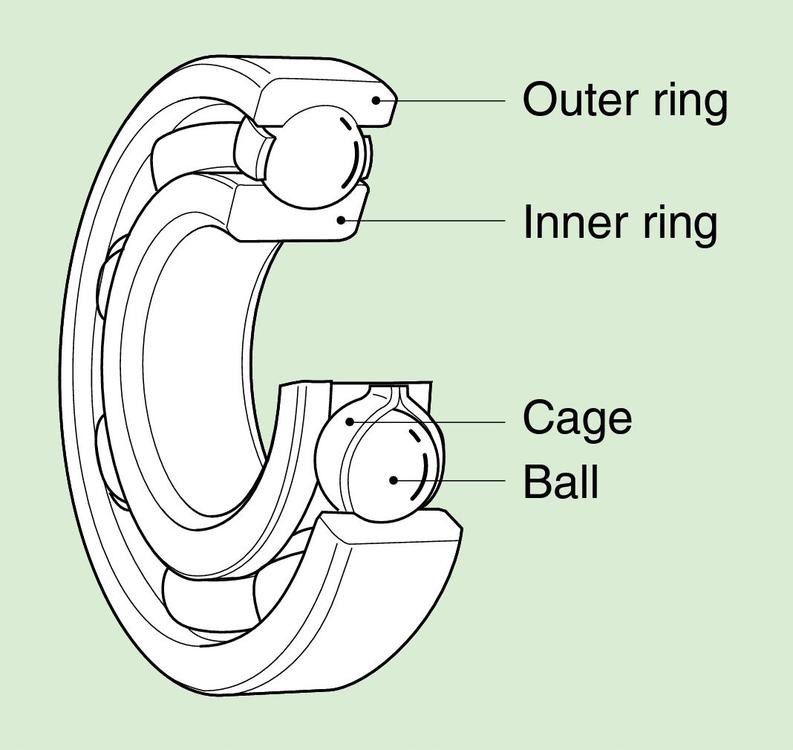

Looks like what is left over from a failed bearing cage (retainer cage) That happens often when some foreign material gets lodged between the balls and the inner or outer ring (sometimes called race). The ball or balls jam and stop for a moment, but the cage is pushed further by all the other balls. This splits the cage open and then it fails shortly after. The top left bearing in my photo shows the rivits clearly in your last photo. I would advise at least replacing the bearings. You wont know all the damage until you strip it down.

-

Won't go into gear

Looks like the diaphragm spring is broken and most probably more than one crack. If it does that, loose section can lodge between the pressure plate cover and the pressure plate hub. The pieces can get thrusted outwards by centrifugal force and jam the hub.

-

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Yeah, I have to give it to the french. They managed to pull that off and get the plane back on the ground in one piece.

-

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

When a joy flight goes wrong. https://www.theguardian.com/world/2020/apr/14/man-accidentally-ejects-himself-from-fighter-jet-during-surprise-flight

-

Thinking about installing an BMW M6 engine in my Z

I'm with Captain. The synchros ard doing exactly what they should do and it's clear you have a synchronised reverse gear. I don't think your problem is in the transmission. Love the gadgets you create to test stuff. Can you fabricate one to push the clutch fork in and measure how far it goes while someone tries to rotated a rear wheel? The rear wheel off the ground and free to spin ofcource. If it does disengage then you can measure how far you need to depress the fork to disengage the clutch. Then you have the data to work out what ratio master/slave movement is needed. Do you still have the orriginal M6 master cylinder? I think you might have a ratio problem with the master and slave. Maybe the M6 master is a lot larger diameter or has a much longer stroke.

-

Won't go into gear

Can you start the engine with the transmission in gear and the clutch pedal fully depressed (clutch disengaged)? If the car wants to take off when you hit the starter, then your clutch is not disengaging. You have 1 inch clutch fork travel and it takes off when you start it, your problem is in the clutch area. Another thing to try with engaging gears with the clutch engaged. Try jacking up the back wheels so at least one is free to spin. I take it you do not have an LSD, then both wheels need to spin freely. This will allow the main shaft to move freely an you should notice it goes into gear slightly easier. If someone rotates the rear wheel by hand it should make it easy to go in gear. What is happening when you try to push it into a gear? Your sliding hub is hitting the spurred gear section of the helical gear. If the spurrsd gears are a little rounded it will worsen the situation. The synchro rings don't do anything when the shafts a not rotating so the hub keeps hitting the spur gear.

-

Won't go into gear

You have a close ratio 5 speed transmission. You mentioned "one exhaust hanger" in your first post. The close ratio has the reverse lock out so you don't hit reverse when shifting down.

-

Won't go into gear

This is normal if the clutch doesn't disengage. If you try and change gear without using the clutch you will find it difficult until the engine is running. When you try to engage with yhe engine running? What happens with reverse? Does it grind or it just won't engage?

-

Won't go into gear

If your slave cylinder is travelling 25mm then your problem is not in the master/slave cylinder. It could be one or more issues: 1. A cracked clutch fork. The fork flexes and doesn't transfer all the movement to the pressure plate. 2. Dryed out input shaft slines or the splined section of the input shaft wasn't lubricated when installed and now dry. This can happen if it has been sitting for a long time. The clutch disc can not move freely away from the flywheel and remains semi-engaged. 3. Seized spigot bearing. That is the bearing in the flywheel that supports the front of the input shaft. It is actually fitted in the crankshaft. If it seizes then the input shaft keeps rotating with the input shaft. All three means you unfortunately will need to drop the transmission to identify and solve the problem.

-

Thinking about installing an BMW M6 engine in my Z

The normal 280Z slave cylinder travels about 15mm +/- 2mm. That is depending on the clutch pedal adjustment.

-

Thinking about installing an BMW M6 engine in my Z

Hi Chris, A couple of questions, might sound obvious, but you never know until you ask. Before you drop the trany, get someone to push the peddle to the floor and check the movement at the slave cylinder and measure its travel. What do you see? Is the clutch throwout bearing up against the pressure plate and the free play (if it's adjustable) on the slave cylinder rod adjusted correctly? Is the clutch disc stuck to the flywheel? After sitting for a long time it could be stuck to the flywheel. You could try starting it in 5th gear to see if it breaks loose. If that is all good, it could be a disc plate not moving freely on the input shaft splines. When you depress the clutch, the disc will move slightly away from the flywheel. Or a spigot bearing grabbing the input shaft. Either way you will need to drop the tranny. Chas

-

240sx door mirrors on a 280z

I think SteveJ is refering to these morrors from MSA P/N: 50-1160 https://www.thezstore.com/page/TZS/PROD/classic02e03/50-1160 I have been looking at the Bullet II mirrors on their site, but they look like they sit very close to the door which would probably have the same poor rear vision.