Everything posted by EuroDat

-

240sx door mirrors on a 280z

I think SteveJ is refering to these morrors from MSA P/N: 50-1160 https://www.thezstore.com/page/TZS/PROD/classic02e03/50-1160 I have been looking at the Bullet II mirrors on their site, but they look like they sit very close to the door which would probably have the same poor rear vision.

-

Parts Refurb

The spray filler is not as thick as the spray puty. Motip make both. The filler is for light sanding scratches.

-

Parts Refurb

It seems to spray on thicker than any primer I have used, rattle can or gun. A trick used with this spray putty was to spray the area and than directly after a very quick wave over with black primer. The idea is not to coat it with black, but to give it a speckle so when you block sand you can quickly see the low spots. Those spots gef a recoat and again with black primer.

-

Parts Refurb

The product I use is the brand Motip https://www.ts24.nl/product_info.php/info/141299/MoTip-Spuitplamuur/?pla_source=14&gclid=CjwKCAjw7LX0BRBiEiwA__gNw2FhZ5mUh_K5KI3XxirtSWVF8Ho3S-RaN6UBna96oFDzaxyvTTp8rhoChWIQAvD_BwE There are other brands https://www.nonpaints.com/en/1k-spray-putty-in-aerosol-spraymax

-

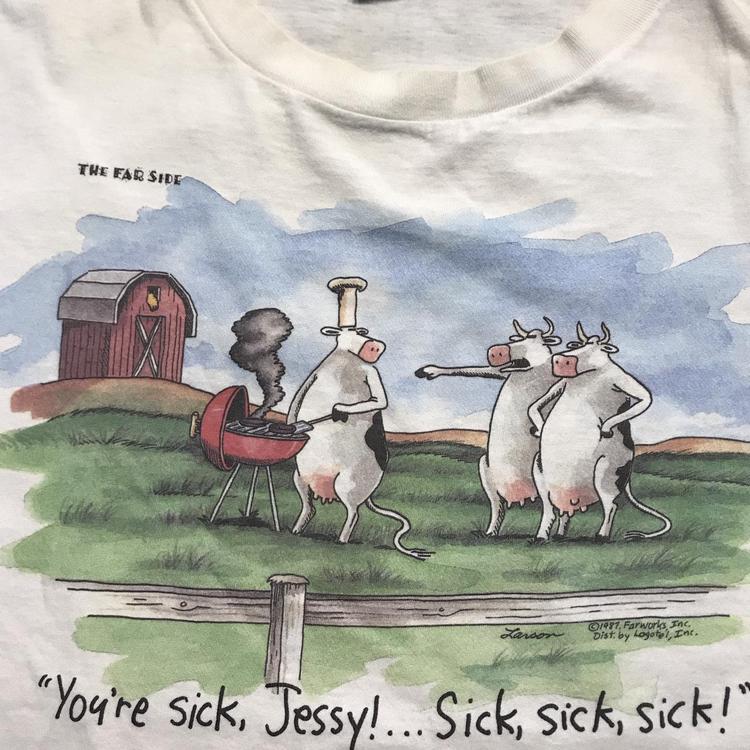

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

This was an insurance ad in the netherlands

-

Parts Refurb

It is Rust-Oleum paint stripper. The enviromentally friendly version which is not as agressive as the normal variant.

-

Parts Refurb

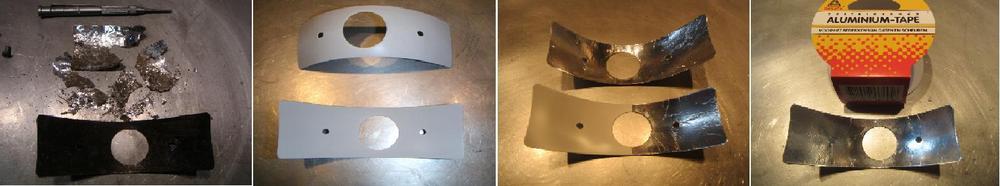

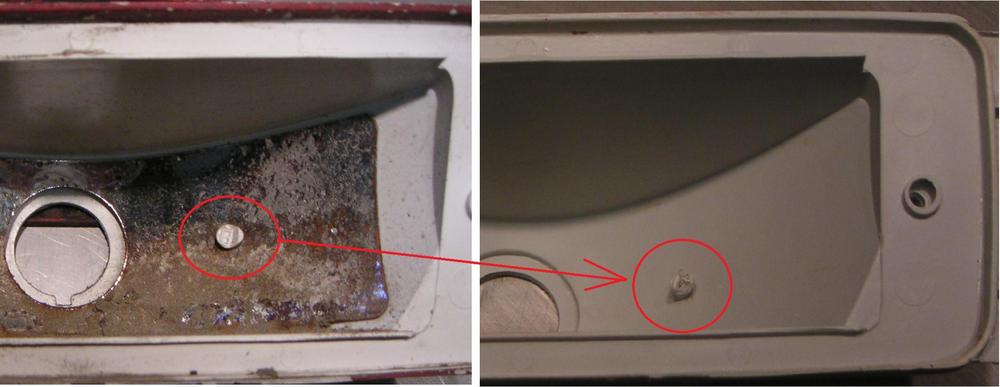

The "procedure" I used is so: 1. Warmed the lens in the refelctor area with a hair dryer to make the white plastic plyable. Not to the point that it would melt, but enough to help it deform instead of breaking off. 2. Used a pair of plyers to squeeze the white plastic "pins" that protude through the reflector. Keep squeezing and moving around the pin and reheating until the plastic reduces enough the pull the refelctor over it. 3. Once you have the reflector off, clean it with a small wire wheel, 40 or 60 grit sandpaper until all the rust is gone. Treat it with rust convertor, prime it and then two coats of spray putty. Sand with emery and add another coat of spray putty. Repeat until smooth. 4. Apply aluminium tape and cut off excess with stanley knife. 5. Fit the reflector over the white plastic pins and use a soldering iron to melt the plastic pins and secure the reflector. Unfortunately I didn't take many photos, but I do have some more of the 280Z turn signal lenses I restored.

-

Parts Refurb

I have a thread here somewhere where I made the lenses and an extended version for the longer LED. Took me a threw attempts to get the colour density right. Luckely the plating on my inspection lights were in good condition and I only needed the lenses. And to think, these were still availble through Nissan for $120 new in the box until about 4 years ago. Who would have thought we would be where we are now.

-

Parts Refurb

I did the "Cheap-arse" aluminium tape method to restore my set too. It turned out ok, but no where near the quality of what @jfa.series1 is doing. It takes a lot of time and dedication Some photos of my humble atempt to restore my TS lenses. I also fabricated new brackets to replace the missing ones and welded the set screws in place. Repaired and polished the lenses.

-

Converting 1977 280z front bumper to 1973 240z front bumper.

I sent JingK a PM, but would like to post some of it here for others that may want to try this at home.... No one makes brackets to convert a 280Z using a 73 bumper set. There probably wont be a lot of requests for this mod either. The 73 bumper protudes further forward than the 70-72 bumpers so they can accommodate the shock demper for the 5mph impact requirements in the US. That makes it a less desirable bumper for the mod. I started this adventure in 2015 to convert my 280Z. Back then there was only one bracket kit available, but it was IMO poorly designed that I decided to make my own. The back bracket was a simple bracket with a slot and one hole. The set with shipping, import duties and GST set me back €232.00 Things have changed since then and the brackets now available have improved considerably. I had the good fortune of lending a, all be it sadly abused looking, 71 bumper to take measurements and some kind members on this forum to give me measuremnts of there bumpers to compare. It is not an exact science. The variance between bumpers and between the 280Z's I measured was a lot more than I expected. I made the slots in the brackets to accommadate the variances I noted, but they will not have enough adjustment to bridge the gap for the 73 bumper. I can fab a set of brackets that will fit, but I need info from JingK. Pending....

-

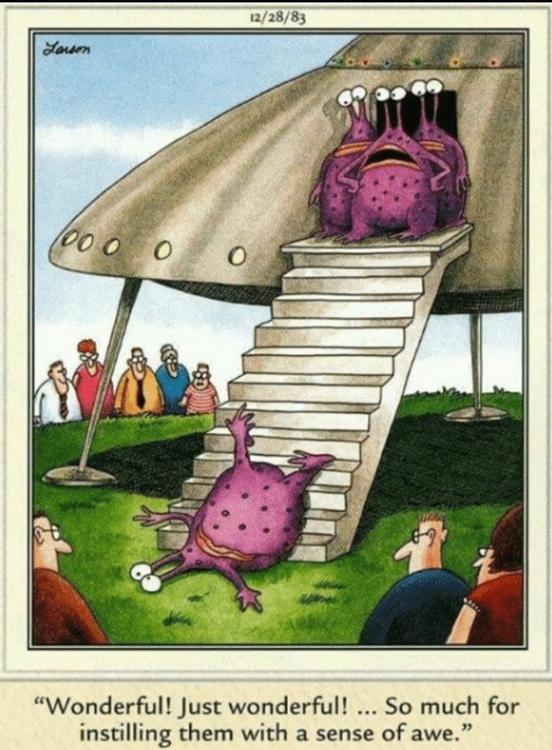

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

- Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

- Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

How to "not" drill a well in your backyard. Dutch style. Hopeless from the start, but at about 1:38 is where it get interesting. I came across this video when I decided to drill my own well.- Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

How to reach those high notes. Lesson 1 VID-20191002-WA0000.mp4- Cylinder head numbers

I remembered a excellent website in Australia that might be some help. You can play with all the combinations. http://www.ozdat.com.au/ozdatonline/enginedesign/- Cylinder head numbers

The chambers in the E31 and N42 are very similar. The N42 does have a little more capacity which will lower your compression ratio a little. Depending on head gasket thickness and overbore you would expect roughly the following compression ratio. E31 = 42.4cc chambers C/R 9.0:1 N42 = 44.6cc chambers C/R 8.5:1- Cylinder head numbers

That is why I said around Oct/Nov. Vin numbers would be a more accurate means of identifying the transition. There are so many points where things change.- Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

- Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

VID-20200322-WA0000.mp4- Cylinder head numbers

I don't know a lot about the fine details, but the E31 was used on the early E31 L24 block upto around Oct/Nov 1970. Your 240Z should have a P30 L24 block with an E88 head. The N42 was on the early L28 in the 280Z leaded fuel version. They changed to the N47 when unleaded was introduced. I know the early E88 had the same chambers as the E31 until somewhere around Aug 71 I believe. Not sure where that lines up with the Vin numbers. The later E88 heads had larger chambers and the E88 on the L26 got the bigger 35mm exhaust valve and the less desired emmision chambers. The valves in the E31/E88 were 42mm inlet and 33mm exhaust. The N42 has 44mm and 35mm. Chambers on the E31 and early E88 smaller than the N42.- Only $1,700.00 for this Solid '73 240Z Project Car in Tucson, AZ

My thoughts. From, shall we say, my european point of view. It's frustrating to see such a good shell and people asking to cut it up. In this part of the world rust is inevitable because of the intense use of salt (past tense) on the roads in the winter. You could restore a rust bucket, strip it down, sandblast it and replace all the rusted sections. An alternative would be to do the same on a relatively rust free rolling chassis and use the rust bucket for parts. Quite feasable for a 72-73 model 240Z.- COVID-19

And Bill gave this speach in 2015.- COVID-19

The government here just made an announcement with the options we have to deal with the situation. 1. Do nothing and let the virus spread uncontrolled. Hospitals most probably won't have enough ic beds. 2. Restrict population movement and contact. The population gradually gets infected and builds up self immunity. Once two thirds of the population is infected the spread will reduce and become managable. 3. Lock down country and restrict movement through house arrest etc to stop spread. The only realistic options are 1 & 2 with preference for option 2. With option two most people with be infected within 3 to 4 months and build up an immunity to the virus. A slower spread will relieve the hospitals so they can cope with the severe cases. That is the theory anyway. I have 5 colleagues with it. One has light astma and he had a lot of trouble breathing. He is feeling better now, but he said it was a lot worse than any flu he has ever had. I don't know when he can start working. Won't be soon. Another colleague said flu was a lot worse and didn't have too much trouble getting over it.- Hitachi 280ZX Distributors

Last month my work sent a crew of 18 to northern Italy for (FAT) acepting two new machines. 5 of them have the virus and are home in quarantine. I have been working from home since and will be allowed to go back to work monday, but my collegue who has the virus is still at home recovering. Worsed of all. The coffee shop must close as from Sunday 18:00h.? https://www.ad.nl/binnenland/nieuwe-coronamaatregelen-nederlanders-hamsteren-massaal-wiet-en-hasj~a861b1ba/- Only $1,700.00 for this Solid '73 240Z Project Car in Tucson, AZ

Looking at the condition of battery tray and the floor section, I really don't understand how this isn't already gone. And someone asked him to cut the roof and tail section off. - Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.