Everything posted by EuroDat

-

Fitting 240Z bumpers and Valences to a 280Z

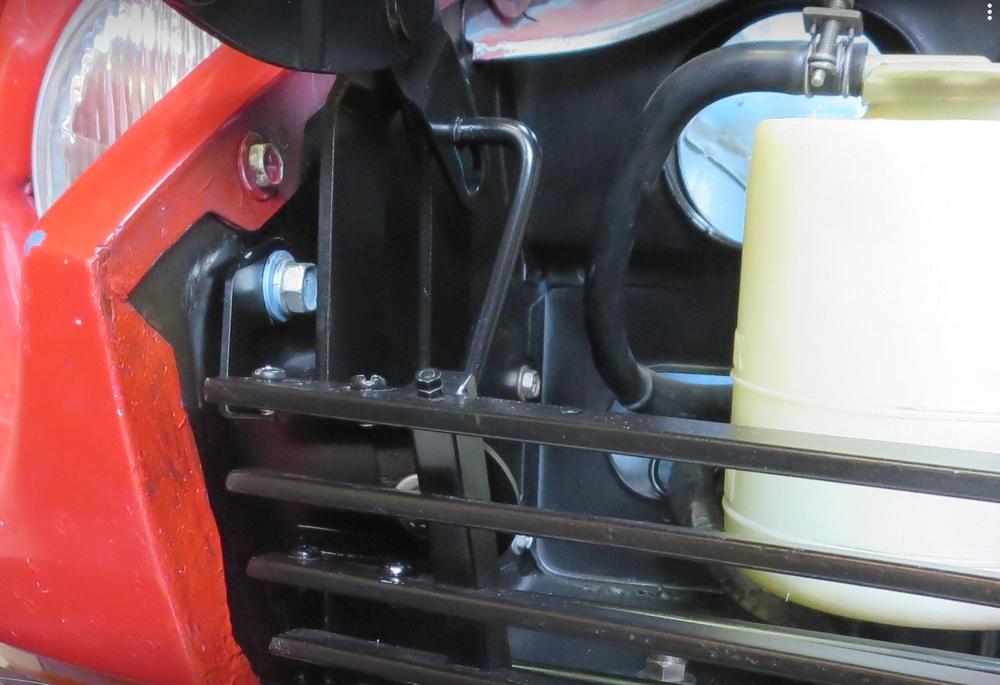

The type 1 can be fitted without dismantling the 280Z turn indicator brackets. You drill the holes through the brackets using the white cardboard template supplied with the brackets. When you go to the skillard or 240Z grill and 240Z turn indicators it's a simple job to remove the bracket. The brackets are spot welded in place. The easiest way to remove them is to drill through the spot weld with a 1/16" drill and them use a 1/2" drill to drill the top section out of all the spot welds. Don't drill all the way through. Gently wobble the bracket and it will break loose. The grill brackets fit to the hood hinges, but still allow full adjustment of the hood. No drilling need to fit the grill brackets.

-

Fitting 240Z bumpers and Valences to a 280Z

If you are looking for bolt on finished product them I hear the carbon fibrd are good, but they are expensive. https://www.thezstore.com/page/TZS/PROD/classic02n01/50-1752 It depends on what you want to do as to which bracket is best for you. My type 1 will give you the most flexability and will work with the skillard 240z and 240z grills. A couple have used the type 1 bracket in combination with my grill brackets on the skillard 240z grill. I'm using this combination on a 240Z grill. The type 2 is like the others offered. It will work on the 240Z, but a couple of bars will need to be cut down. Both brackets will work on the 280Z grill.

-

Fitting 240Z bumpers and Valences to a 280Z

If you are going fibreglass, Motorsport Auto (thezstore) is where I got mine. You will need to work on the finish a little. https://www.thezstore.com/page/TZS/PROD/classic02n01/50-1750 When I started this thread no one made any descent kind of bracket. I did try to order a set, but was disappointed in what it was. I still have them somewhere in the garage. That is when I decided to make my own. I have been making the brackets for a little over four years now, but others make them now too. You can buy theres through TheZstore. Mine are stainless steel and a little cheaper, but its up to you what you want to do. I do make two styles. One so you can really use a standard 240Z grill or the Skilard 240Z grill and 240Z indicators in a 240Z air-dam or keep the 280Z indicators and 280Z grill. I think I'm the only one making the first option.

-

5 speed worn bushing prevents reverse?

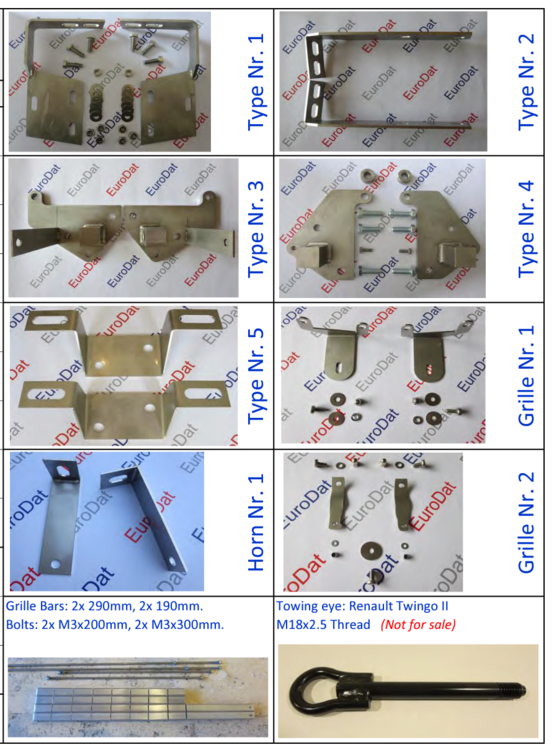

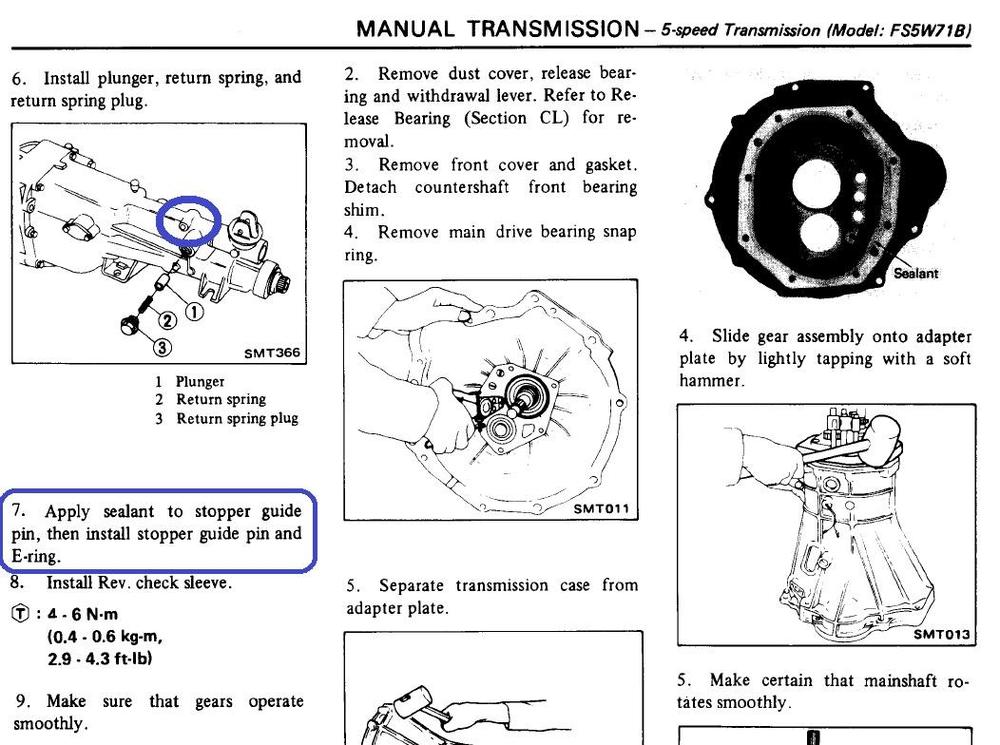

Another thing to check. It doesn't have anything to do with your problem, but the stopper guide pin is a common source for oil leaks. I use a silicone type sealant suitable for oil environments to cover the exposed ends of the pin and create a good seal.

-

5 speed worn bushing prevents reverse?

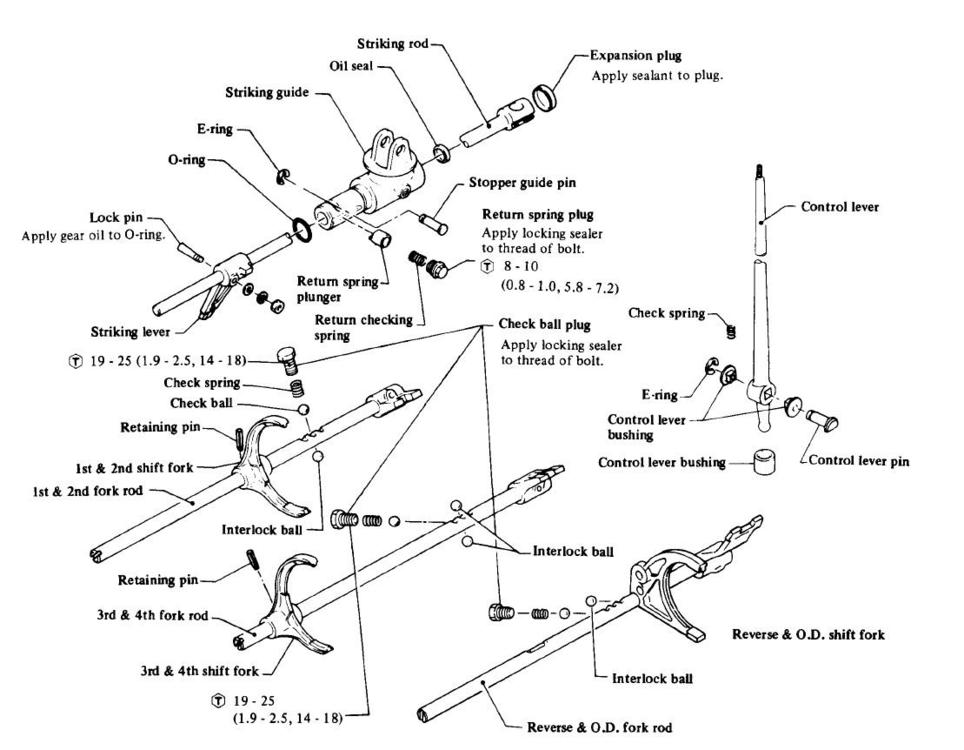

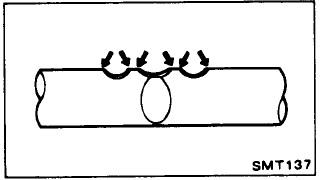

The movement you see the your video is normal. The hole "bushing" where the selector shaft goes through in not a tolerance fit. It has a large clearance so splash oil can pass through to the striking guide and striking rod contact points. When the transmission housing is bolted together and the striking rod is supported by the front housing section the excessive movement will be gone. Did you have this problem before the rebuild? Did you replace any parts in the reverse gear section? Like Dave mentioned. Is the selsctor rod hitting and binding in the striking guide? Other things that can cause difficult shifting: - Tolerances in new parts - Bent selector fork rods - Worn or damaged interlock springs or balls. See SMT137

-

R200 Comparison

I'm wondering why you want to go with a R200. Is something wrong with the original 240Z R180? You could consider a Subaru Impreza WRX STI R180 with a 3.9 ratio.

-

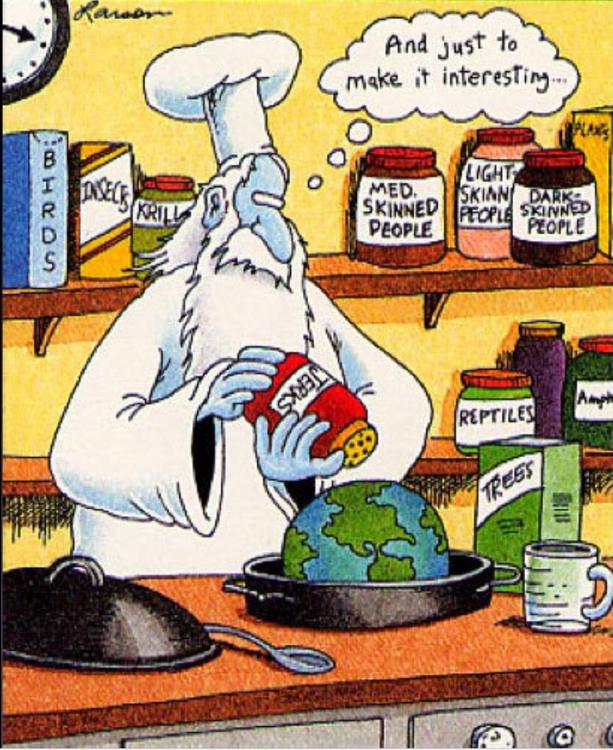

Rockets from Iran hitting US bases in Iraq now

Yeah, that is the problem with jerks. They seem to be sprinkled all over the place. Given enough time and you will find them.

- 1976 280Z Restoration Project

-

Aussie fires

I have some friends in the hunter valley area up near Muswellbrook and Maitland. They are still fighting fires in the area. My mate is a volunteer SES'er, but spent the last 3 weeks helping the rural fire brigade.

-

Scarab Conversion Kit on DPAN Facebook

Is it just an engine conversion or also including a body kit? In the photo it is not so clear what you are getting and it looks like some parts are already used. I don't think there was a truly standard Scarab model. You basically ticked off all the options you wanted and they converted a 240Z or your own car. You could also do it yourself. Can you post more photo's for prosperity. It's the first time I have seen the parts not installed on a car.... You never know, someone might want to make a kit based on the parts in question.

-

280z AFM lead?

I think that spade connector is a legarcy from the early Bosch system they used in the first 280Z's I have seen it on an Alfa over here.

-

Holiday Cheer

-

78 280z Thoughts

I would definitely consider using a relay system running through the oil pressure switch for safety reasons. Maybe a dual relay. One to run the pump during cranking and after the engine starts it would run on the second relay.

-

78 280z Thoughts

You can remove the EFI harness completely, but you will need to make a relay setup to run the original fuel pump and use the oil switch to activate the fuel pump. If you do use the original fuel pump, how do you plan to regulate the fuel pressure? I concur with the above. Change one thing at a time otherwise you will have issues and won't know where to focus your attention.

- Help with Throttle Position Sensor 78 280 Z

-

1977 280z Light Restoration Project

When you heat it, try to heat the aluminium and don't point the flame at the plug. You want the aluminium to warm up and expand and reduce the contact stress.

-

Starting Series 1 after 15 years

I think I would try priming the system through the oil sender switch port. Removre the oil sender switch and find a fitting that will fit. Any pump will do to pump some oil in. Even a simple bicycle pump will do. I don't think you need a new pump because it has been sitting for a while. It is just being difficult to prime after sitting so long.

-

Starting Series 1 after 15 years

I did the same when I bought mine back to life after 19 years. Removed the spark plugs so the starter had an easier job turning the motor. It took about 4 x 10 - 15 second goes to get the oil up to the cam.

-

78 280z died and won't start back up

Water could be your problem. I had a similar issue, but it happened after I tanked the car. If you suspect water is in the fuel system, I would take a sample close to the engine. It is easy enough by removing the return line going from the FPR to the tank. That is the line that goes from the engine next to the fuel filter. Its very low pressure so no worries about fuel spraying everywhere when you disconnect it. Find a 2 litre container or an extra length of hose to a bigger container. Anything bigger than 2 litre is hard to get into place to catch the fuel. Run the pump and catch 1 - 2 lires of fuel, let is settle and check for water. See photo for what came out of mine. TIP: To run the pump without cranking the engine endlessly. Not good for your starter or battery. Unplug the wire with the spade shaped terminal on the back of the starter. Follow the big starter lead to the starter. It is located above the two big M8 terminals. See second photo. Now if you hold the ignition key in start position the engine will not crank, but the pump will run.

-

78 280z trans/clutch/flywheel advice, car sitting 12 years!

I ended up draining the radiator, removed the top hose from the radiator and the top section of the fan shroud. With the car's scissor jack under the engine, I could lower the rear of the engine and that gave me more room to get the bellhousing under the firewall.

-

Fitting 240Z bumpers and Valences to a 280Z

Hi tool man, 1: Yes. You will need to drill an extra hole to fix the bumper side arms. I don't have any photos of that part modification. I was at the stage where I just wanted to finish it. The hole is about 100mm in front of the 280Z bumper hole IIRC. I can check mine, but it would be better to measure and determine the position in your own situation. 2: yes. It will fit under the gap shield. Not sure how that will look though.

-

AFM upgrade questions

The aftermarket throttle bodies are made for after market ecu like megasquirt etc. Then you have the ability to tune for performance and the extra capacity the throttle body can give. If you don't want to use your flywheel, you could buy one that is already lightened. There are still companies out there thaf lighten them. Zcardepot sell one variant. https://www.ebay.com/itm/Datsun-1970-83-240Z-260Z-280Z-280ZX-Competition-Clutch-Lightweight-Flywheel-161/323799190475?fits=Model:280Z|Make:Datsun&epid=1545121518&hash=item4b63ef8bcb:g:UscAAOxy039TKLJl&redirect=mobile They are all around thd $350 - $400 mark. I don'tknow if buying a new flywheel and having it lightened would be any cheaper. You would need to find someone with experience in these flywheels. Plenty of suppliers with kits including the flywheel. https://www.ebay.com/itm/TR1-STAGE2-CLUTCH-KIT-FLYWHEEL-For-1975-1983-DATSUN-280Z-280ZX-2-2-TURBO-L28ET/333165142490?fits=Model:280Z|Make:Datsun&hash=item4d9230a1da:g:qBIAAOSwXNdcXLKm&redirect=mobile Be carefull when buying a flywheel. You don'twant the one for the nissan trucks (D21) etc. The flywheel is heavier at around 28lbs. Not what you want.

-

AFM upgrade questions

If you want throttle response, you won't get much by doing that, if any at all. These old efi systems don't like alterations much at all. It unbalances the components and the ecu can not compensate. It doesn't "learn and adjust" like newer sysrems can. Changing to a sport air filter or a larger exhaust system can help a bit because they are outside the components and could be restricting the flow, but extractors can change the scavenge of exhaust gases and that could have a negative effect. The easiest why to improve throttle response on these ols efi systems (without changing ecu, cam, head etc) is a lightened flywheel. The standard flywheel is 23lbs. If you get one that has been lightened to 16-18lbs or lighten the one you have, it will repond a lot more the the throttle. Or an aluminiun, but they are around 11lbs and that will reduce drivability a lot. Some people don't have any problem with the touchy throttle. You could match that to a 240mm clutch out of a 280Z(X) 2+2 or a 280ZX turbo clutch. That would gain a little weight over the standard clutch and would give you a heavy duty clucth with a light peddle. https://www.summitracing.com/search/brand/fidanza/year/1978/make/nissan/model/280z/part-type/flywheels?SortBy=Default&SortOrder=Default Not trying to be negative, but a lot of changes often make the engine sound better and we think that makes it faster, but it's often our mind playing tricks on us. That sounds fat cool, so it must be faster. If I change anything to my car, I go to a quiet road near home and do a simple test. I drive at at a certain speed, say 20 mph and give full throttle till it reaches 70 mph. Don't change gears during the test.. Have a friend (or my wife, if she is in the mood to waste time helping me on this thing) video the speedo and tacho and compare that with the results after you do the mods. If the time reduces, than you made an improvement. You can plot the speed versus time in excel and get a kind of power curve. Plot both before and after and you can see if it improved in certain areas of the rev curve.

- Transmission rebuild help

-

SS Bumpers from Vietnam

Looks like a neat job you did on it Jim. Your car looks brilliant.