Everything posted by EuroDat

-

78 280z idle problem

You could have a couple of issues that cauld cause an overfueling problem. Most common are leaking injectors, leaking CSV or a bad temperature sensor or wiring going to the temperature sensor. The more resistance the colder the ECU thinks the engine is and compensates with more fuel. You seem to be getting a lot more fuel than a faulty temperature sensor would allow, but doing the checks will confirm or dismiss it. When you check it, do the check at the sensor (sensor to ground resitance) and than again at the ECU connector (Connector pin 13 to ground resistance) They should be the same. Refer to the bible for the correct resistance for temperature range. Note: Use the 1980 Bible. It is for all models 280Z, 280ZX en 810 Maximas up to 1980. The other book is for the 1974 to mid 1976 models.

-

Sounds like spinning of the "Wheel Of Fortune"

When you turn the diff by hand the other wheel often drags on the brakes etc and doesn't turn. What happens then is the internal spur gears in the diff rotate and the propshaft speeds up. That is what you are most likely feeling or maybe even hearing. They are designed for turning so the outer wheel can speed up and the inner wheel can slow down.

-

Sounds like spinning of the "Wheel Of Fortune"

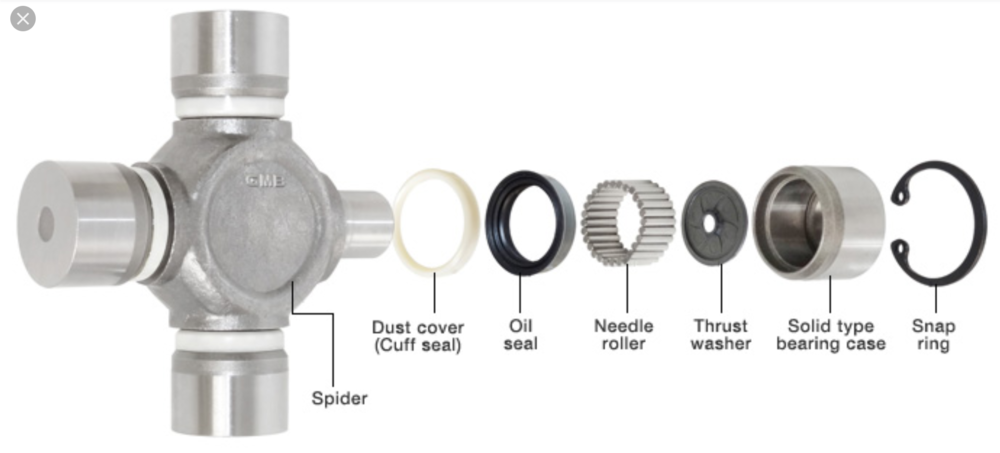

I have missed a bad uni-joint by checking for play with a really big screw driver. The play is minimal and depends on where the neddle contacts the spider when testing. The neddles could be on a ridge of the vertical lines. I think that is what happened to me when I missed the bad joint I had in an Escort. Finally changed it and click sound was gone. It was half full of vertical lines on two of the spiders pegs. https://www.howacarworks.com/transmission/how-to-check-u-joints Here are two screenshots of the spider pegs. Note on the second screenshot, the peg on the top side of the photo has the lines on the driven side and the bottom peg doesn't have them on the non driven side.

-

Sounds like spinning of the "Wheel Of Fortune"

Are you drinking a Macdonalds coke in the rattle2 audio? ?? Sounds like it at 45, 101 and 110 seconds. Sounds a bit like uni-joints. They can be hard to check in the car. Generally when a uni-joint fails, the needles create vertical lines in the peg section of the spider. Mostly about a third of the peg on the driven side develops the vertical lines. Acceleration and bumps change the geomentry of the rear axles and needles can click over the vertical lines.

-

Sounds like spinning of the "Wheel Of Fortune"

I agree with jonbill. It doesn't sound like a diff noise. In your first post you mentioned changing the diff. Did you replace the diff or just the oil in the diff? If you changed the diff and it is still making this noise, it's not the diff internals.

-

78 280z idle problem

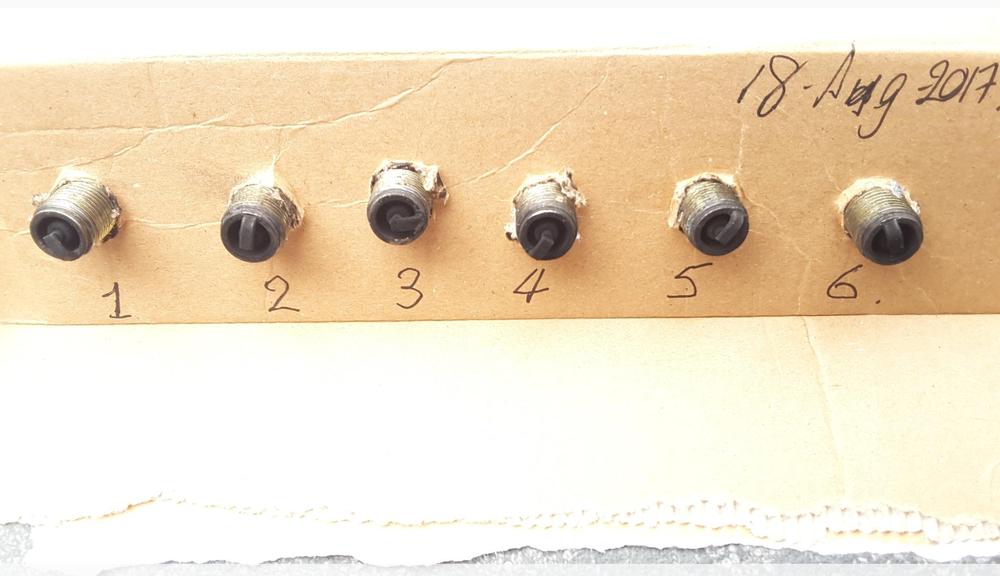

Ther could be a couple of things causing it to run while the pump has stop. Idling is essentially a no load situation and requires minimal fuel. It looks like (not confirmdd yet) that you have a chronic over fueling issue. You might even have fuel laying around in the inlet manifold. Stop the pump and the air/fuel ratio starts leaning out and it briefly runs better. Well, it's a theory... You NEED to buy a fuel gauge and mount it in the line after the fuel filter. Don't assume stuff. You need to test and confirm or dismiss possabilities. Not doing that will set people on the wrong train of thought and you will be chasing you tale for weeks. Been there, done that, so to speak. The people here can and will help you a lot, but you need to give them solid informatie. Tests you should do asap. - Fuel pressure: If it is a leaking injector or Cold Start Vavle, you can confirm that with the gauge. Ill try and upload a simple procedure I use for testing. Need to find it on my tablet... - Check the spark plugs. That are probably black and sootty from overfuelling. Remove them and stick them through a piece of cardboard with the cylinder number written next to it. Make a photo and post it here. See attachment sootty plugs from a badly leaking cold start valve CSV. - Compression test. Do a compression test and confirm all cylinders are in goed order. It's not that important what the reading is, unless you are reading 75psi on all cylinders.... Most compression gauges are not calibrated accurately showing pressure so 140 could be 160. What you are looking for is variance between the cylinders. They should be (for example) all 135-145psi. Bad would be something like 4 cylinders reading 145psi and two reading 95psi and 110psi. - Read and start doing the tests in the fuel injection bible. There is a very good reason why we call it the bible. Instruction - Fuel Pressure Test 280Z RevB.pdf

-

California 1978 Datsun 280z Restomod

I have wondered that too. I know older cars with leaf spring suspension used them to protect the yoke from stones etc scratching it. Leaf springs would push the yoke in and out of the transmission when they moved up and down. That doesn't count here because the rear diff on a 280Z is virtually fixed and does not move forward. Preventing oil from slinging all over the place sound as good as any.

-

78 280z idle problem

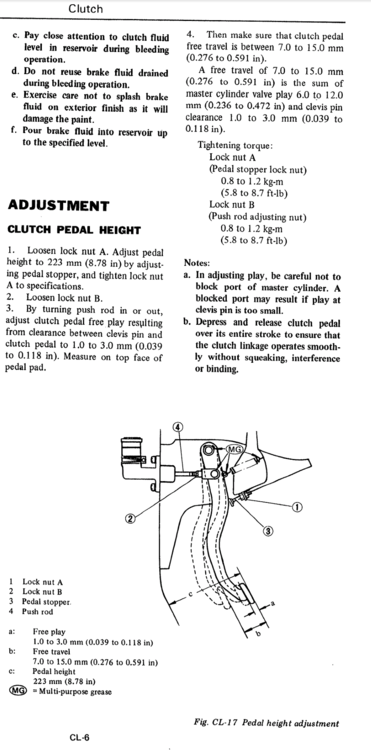

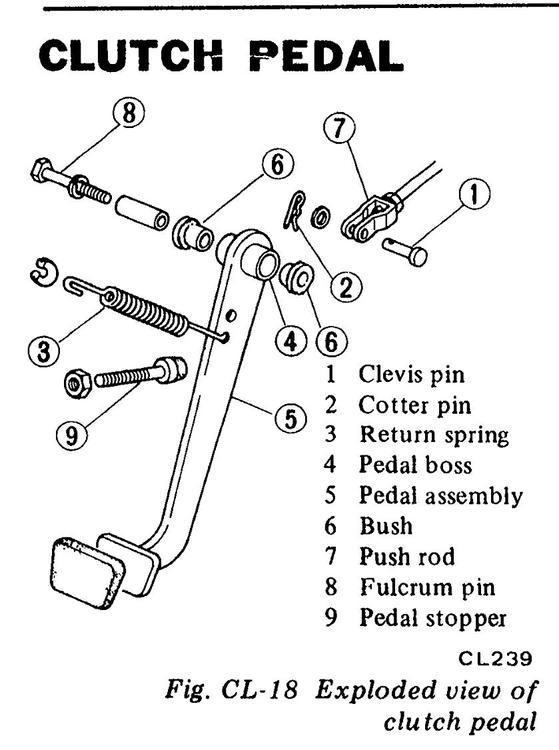

I thought the master cylinder was replaced earlier before the clutch and pressure plate was replaced. Now reading post #39 I agree. My internet connection is not the quickest working out of a landcruiser or campsite and I scrolled past it. Chaseincats has a good point. It looks like an incorrect master cylinder push-rod or adjustment. If it has the correct push-rod it should be adjusted according to fsm. See attachment. .

-

78 280z idle problem

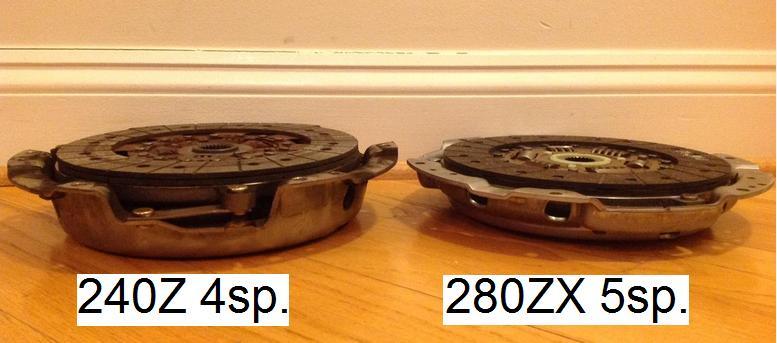

The problem is that the aftermaket industry doesn't really know the difference between all thedifferent models and pressure plates. 240Z up to 72, 240Z after 72, 260Z, 280Z and 280ZX up to 81, 280ZX after 81 and Maxima 810. See attached photo's. Btw, They are not my photo's. Other people having similar issues.

-

78 280z idle problem

When you changed the clutch. Did you compare the two pressure plates. There are basically four different heights available. The magical number between the flywheel and where the clutch fork contacts the collar is 92mm. The collar must match the pressure plate. Very easy to mix them up when using aftermarket pressurs plates. Measure the fork position in rest. From the front of the transmision bellhousing to the clutch fork should be around 115mm. If you measure 120-125 then the clutch fork will bind on the transmission housing before releasing the clutch.

-

Transmission leak

The parts you are asking for can be sourced at any aftermarket parts dealer or direct from Nissan. See attached list. Nissan Part numbers are: O-ring 24x2.5mm P/N: 32710-14600 Seal 14/20x4.2mm P/N: 32858-U6702 Material: NBR Tranny_Rebuild_FEB2012.pdf

-

Clutch not fully disengaging

I have not seen any measurements fro the pedal adjustment. Did you follow the procedure in the manual for adjusting the pedal and slave cylindrr rod? Don't assume. Do the checks and tick of the list. A blocked port in the master cylinder or insufficient pedal travel can cause a lot of hartache. Push the pedal to the floor and note where it touches. Measure from that point. I made some screenshots of the 72 FSM for the slave cylinder and the 77 FSM for the pedal adjustment. I find it a little clearer. Though it helped (me) to read it twice?.

- 27 replies

-

-

- 2

-

-

- 240

- advice

- clutch

- drivetrain

-

+7 more

Tagged with:

-

Clutch not fully disengaging

Hey guys, Why are we talking about replacing the clutch. His problem is the clutch does not disengage properly. If it was slipping, then I would suspect the clutch. A list of things that can cause a dragging clutch - Clutch master cylinder push-rod wear and adjustment. - Slave cylinder push-rod wear and adjustment. You should have the adjustable push-rod type with the return spring. - Worn out master cylinder and/or slave cylinder rubbers. The slave cylinder you should see leaking fluid at thr push-rod. If the primary piston cup in the master cylinder is leaking. It will leak fluid back to the master cylinder resiviour and the clutch will loose travel. You will notice this in 1st and reverse firstly because they are standing start applications. You can check this by depressing the clutch peddle and holding it on the floor while someone watches the slave cylinder push-rod. If the clutch fork slowly returns then you have a laeking primary rubber cup in the master cylinder. Other things that will cause a dragging clutch and require removing the transmission to inspect and replace. They are not so common, but do occur occasionally. - Dry spigot beering in the end of the crankshaft. A very dry spigot bearing will drag the input shaft with the crankshaft. - Dry or rusted input shaft splines. When the pressure plate disengages the clutch plate, the clutch plate moves along the splines so to release it from the flywheel. If the clutch plates movement is restricted, it will disengage fully from the pressure plate, but not from the flywheel. Don't just assume its right. Follow the FSM for adjusting the master and slave cylinder push-rods. I posted the position of the clutcgh fork in relaxed and depressed positions. I can't remember of the top of my head and I'm not really closeby to civilisation atm. Ill try to find them. That would confirm the correct travel and the collar is correct or not. I would be doing these checks first before taking any steps to remove the transmission. Ok, I found the other thread.

- 27 replies

-

-

- 2

-

-

- 240

- advice

- clutch

- drivetrain

-

+7 more

Tagged with:

- Death of a Black Pearl

- 280Z fusible links

-

Transmission leak

It's hard to see in the photo and my internet here, in the middle of nowhere, is not the best. Can you get a better side on photo? It might pay to do some more checking before removing the transmission. It could be just a leaky rear oil seal and the yoke is throughing it up around the striker arm. I would clean it, drive and check again to confirm before removing the transmission. Replacing a rear oil seal is a lot easier than pulling the transmission. These transmissions can also leak at pin (pos #8). It's not common, but possible. Some Nissan garages in Australia used to cover the exposed ends of the pin with silicone sealant as a precaution to prevent leaking. These old transmissions have wear and the tolerances could allow enough oil to leak through the pin boring. The o-ring seal (pos #3) is after the pin.

-

Play in rear strut

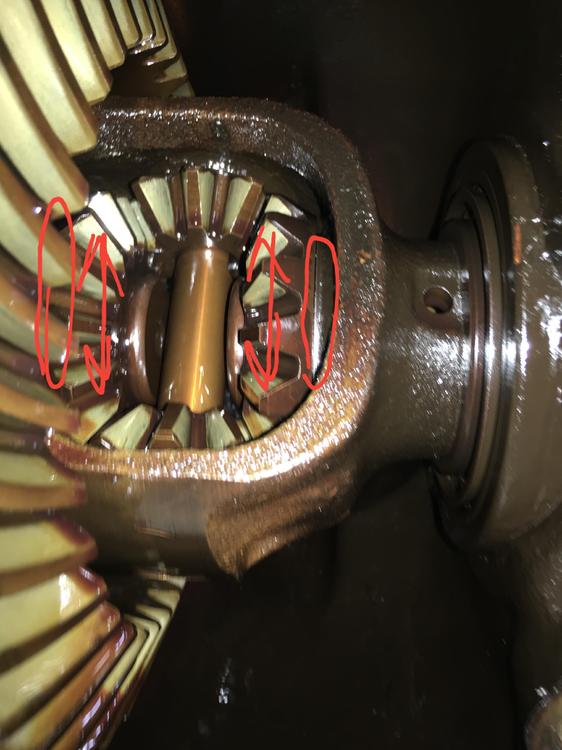

If the rest of the diff is in good working order, you can fix this problem by replacing the thrust washers with a thicker spec washer. The clearance should be 0.1 to 0.2mm. You will need to remove the centre and the ring gear. Then you can tap out the roll pin (27) and pin (23) will tap out easily. The thrust washers are (26). Someone might want it or it could be a good spare.

-

Play in rear strut

It's most probably caused by excessive end play in your spider gears. Thats the 4 gears in your diff centre. The two larger gears (where the axles slide into) will move back and forth. It's caused by the wear in the thrust washers behind gears. They can wear, especially when people do one wheel burn out. My excusses for my poor drawing talent on a tablet. The arrows are the back and forth movement and circles are where the thrust washers are located.

-

1970 240z uk project

Jason, Congrats with the progress you are making, specially with set backs you had with painting. I'm impressed with the mustache bar rubbers find. They are rare items these days. Last time I heard someone finding a nos set was back in 2014. I like your caliper/disc combination. That is a nasty little crack in the steering rack. I have never seen one crack like that. Most just worn out internals.

-

Transmission Crossmember Mount Bushing (Rubber)?

You will feel a little more engine vibration through the trany mount with PU bushes. It's no where near as bad as the mustache bar insulators on the diff. For street cruising I would keep the transmission cross member and mustache bar mount original or find a good donor car to replace them like I did. I tried PU on them and now back to the original style

-

Hello from across the pond! Searching for a 240z

Thats a neat brake conversion. I see the big bore master cylinder and parts to convert the discs, but no parts for the rear. What did you do to maintain balance with the rear and what is your set-up for the rear? You could probably remove the balance valve internals altogether now you have so much braking power on the front. I'm running porterfield R4-S pads and shoes on a standard set-up and very happy with the results. The car is only used for street driving. PS: The air intake mod looks great. First time I have seen that on a SU set-up.

-

Transmission / Differential Combination

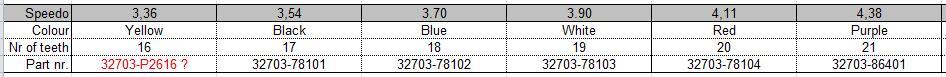

It will be drivable, but you will shift up to second a lot early than you are use to. Hill starts are going to be a lot easier;) If it is temperary I wouldn't worry about it much. You did grt the speedo gear when you picked up the tranny diff combo? You need the white one with 19 teeth. See attachment. The guys in the 620 trucks don't know any better. Thay have the earlier pre 1977 280Z 4 speed with the 3.592:1 first gear and a 4.375 diff. So a 3.321:1 with a 3.9 diff is tall but not the worst combination you could come up with. There are people that use the close ZX transmission with the R180 diff and 4.11 gead setup. Thats close to what you will have in first gear. My quick calulations with 14" wheel and tyres with a diameter of 620mm (my situation) you will have a speed 31.62km/hr @ 3500 rpm compared to the original setup 34.79km/hr @ 3500 rpm. You will loose about 10% on speed. Thats basd on the final ratio of 11.77 for the 3.545 diff and 12.95 for the 3.90 diff, and the distance of 1.95mtr travelled per revolution.

-

620 5 speed

The 620 used the L16, L18 and L20. They have the same bolt patern and bolt position as the L28. It will bolt in, but first gear will be very low. I think the 620 has a 1st : 3.592:1 280Z 1st : 3.321:1 280ZX 1st : 3.062: 1

-

Used 5 speed

Like Dave and Zed head have already said. If you can crack it open and visually inspect the synchro teeth, that will give you a vry good indication of its condition. If you can not (not allowed) open the transmission case, it will always be a gamble. A shot transmission can feel very good when turning it by hand I have a list of all the normal wear parts and the rear extension house bush part number and manufacture. Most of the parts are still available through Nissan or aftrrmarket.

-

280z 5-speed into a 240?

Here is a simple excel file that shows the different speeds per transmission/diff ratio. Calculate ratios 01.xlsx