Everything posted by EuroDat

-

1976 280Z Restoration Project

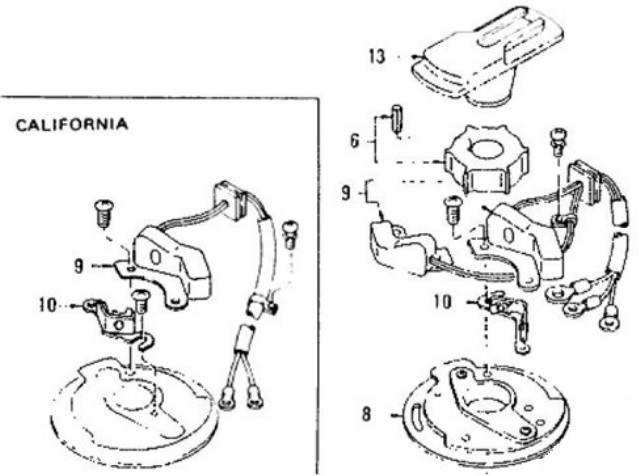

Mark, Your 76 should be using a D6F4-01 distributor. It has a dual pick-up/reluctor set up to create a 6 degree phase shift in the timing. When the temperature switch is open it will retard the timing 6 degrees. Anyway, you don't need any of that. Just choose one of the pick-up coils and use it to trigger the (HEI) TIU. I would remove the other pick-up coil because it can generate 50 volts when the engine is running at high speeds and could cause arcing in the distributor. If you have a look in the distributor, it will make more sense. You have two options with the distributor. Keep your pick-up coils or buy a new one for a 77 from Rock auto etc.: 1a. Keep your pick-up coil. You will need to keep the brown wire and the green or the red wire and the green. Don't use the red and brown. Which ever pick-up coil you choose, remove the other pick-up coil and its wires. The green should split of to both pick-ups. 1b. Buy a new 77 pick-up coil, it will bolt in with no modifications, and wire it as per the 77 instruction (green and red wires). 2. Disconnect the white wire. You can remove the water temperature relay. Its located on the right inner fender relay cluster with the voltage regulator . The rest is the same as the 1977.

-

1976 280Z Restoration Project

Mark, You have basically the Fed model with a dual pickup. You can use one pickup (green or red) with the brown, and it will work fine. The white one is for the temperature switch, but the HEI module won't use that. The FED/Canadian models hed a retarded timing when cold. This diagram should help. TIU280Z1976_REV1.pdf

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

-

Carbon fiber bumper on '73 Z: bracket modification ?

The 73 had a different mounting bracket because they started with the heavier bumpers. That is why the bumpers wont fit. You will need to make a set of brackets to convert to the smaller lighter bumpers.

-

'75 280z can't get spark

Good to see you found your problem. Feels good to hear it running again, doens't it.

-

'75 280z can't get spark

Tamo, You should see 12 volts (Battery voltage) on "R" terminal with the brown wire. Test it with the Multimeter negative to ground. Steps I would do: 1. Use your multimeter to measure battery voltage at the battery. 2. With ignition key on, check voltage at harness terminal "R" . Should read battery voltage. Anything less will meant you have resistance in the wire somewhere. Like Jim mentioned, check while cranking the engine as well. The voltage will then drop because of the load on the battery from the starter, but it should be about 9 - 10 volts. 3. Disconnect the IC from the pick-up coil in the distributor. Use the multi meter on the lowest VAC setting and measure ther voltage peaks from the pick-up wires while cranking the engine. You should see peaks. Sometimes easier the read the bar graph on the multi meter display. The 82 distributor has a better piuck-up coil than the 280Z model had, and should read about 0.5VAC to 0.8VAC at cranking speed. I assume you are not getting any spark? That sounds bad, but it is easier to find problems when it doesn't do anything. A lot easier than a system that stops every now and then, like mine. You can't test the IC with a volt meter. All you can do is eliminate all the other possibles and come to the conclusion it's the IC.

-

Transmission internals question

Theymight be hard to find. 6 years ago I replaced a lot of stuff in my transmission. The parts came from my local nissan dealer, but now he tells me that theh are nla. Can you post a photo of the inserts now they are out? If you do choose to use to old ones, they will be in the correct direction. The sleeve won't ride off the end and chew it up like it is now. The teth on the end of the sleeve that engage thegear are what did the damage and they will not make contact once its in the right way. It won't be perfect, but if you clean it up, you could also brazed it and filed down. Welding might distort it to much. Remeber once its in the right way, it won't have such a hard life with the teeth from the sleeve riding over it.

-

Transmission internals question

I changed two drawings in the 280ZX 1982 manual. It makes the direction of the 5th gear insert more clearer. See page MT-4 and MT-10. Comments are welcome. If its ok Ill ask Mike if he can replace the exiting MT file in the tech section. mt - 280ZX-82.pdf

-

Transmission internals question

I had some time this afternoon, so quickly removed the rear extension housing and took a couple of shots. The inserts are fitted like in the diagram SMT986 and the ctross sectional view in SMT530. I will try to find some time during the week to add a sketch to the pdf's

-

Facebook vs Forums

A dear friend said to me, jokingly, "I have a very interesting life, and the rest I post on facebook". I have heard it before, but it sums it up well. For me: Facebook is a social medium and forums for the more technical stuff. I'm not much of a facebooker.

-

Transmission internals question

Yes, It's an issue I had with the manual. The assembly section only warns you to mount the hub in the correct direction, but doesn't say anything about the inserts. They managed the neglect that all the way through to 1983. It looks like they corrected it in the 300ZX 1984 transmission.

-

Transmission internals question

Hi Dave, I was thinking that too, but it's been two years since I have had one of these later 71B versions apart and 5 years ago for my own transmission. Ther reason why is because I remember problems with the manual. It shows the inserts in both directions, depending on which diagram you look at. I did make a simple sketch when I pulled mine apart last time, but I can't find it now. See the two drawings in "5th shifter inser.jpg" for what I mean. Looking at the snapshot I made, I would be 80 - 90% sure it is in backwards. It also explains the damage to the insert. The assumption that this is the first time the transmission is apart would not be correct. If someone pulled my transmission apart, they could make the same assumption, because I used new bearing retainer screws and nissan gaskets. I can pull the rear extension from one of my spares tomorrow and check.

-

Transmission internals question

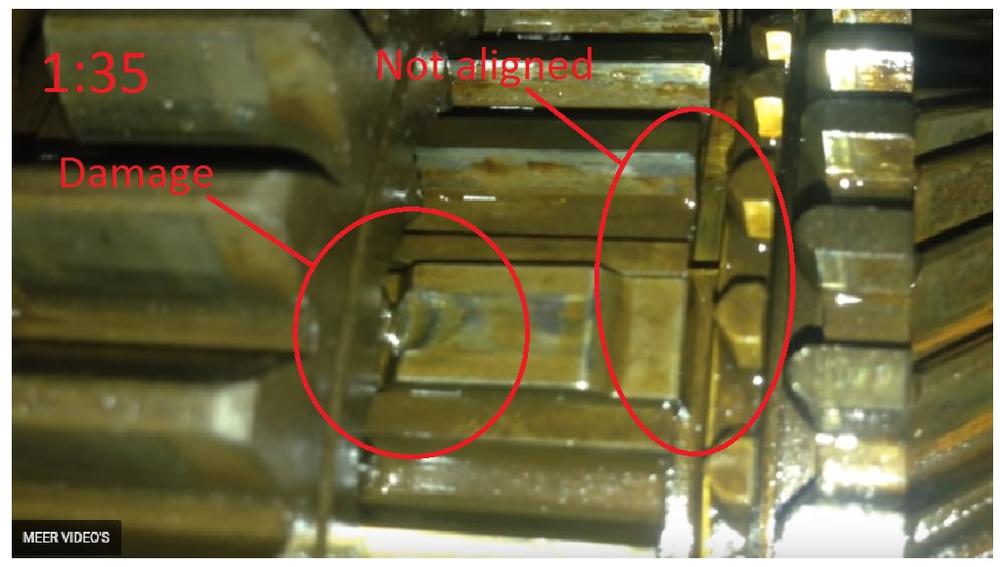

Hi Guys, Sorry for being a little late replying. Been away for work. A little background info about the 5th baulk ring (synchro): A good idea to use the Nissan terms for the parts. It makes it easier when refering to the manual and the parts catalogue. Synchronizer assembly: Hub, Inserts, Baulk ring and Coupling Sleeve The "carbon ring 5th baulk ring" was in the 280Z wide ratio transmission. Its not the porsche type synchro, people talk about, in the 5 speed that was available in the 240Z outside the north amaerican market. Nissan changed to the brass ring in the later 280ZX transmissions, and the wide ratio 280ZX 2+2 eventually got the brass ring 5th synchro. The synchro rings are the same for the 71C model without the reverse synchro. 1st to 4th are all the same size synchro rings (P/N: 32604-P0100) and 5th is smaller (P/N: 32604-E9801) Looking at your video: Part 3 of reverse lock out on 280Z. The reason you can’t get it to engage 5th is simple. The coupling sleeve is moving too far forward allowing the insert to lift up out of the slot in the baulk ring. See snapshot (Not aligned). This is because you are doing it by hand. The selector mechanism should not move it so far forward, like you mentioned towards the end of the video. You also confirmed it when you assembled the rear case and selected 5th gear. If you look closely in the video at 1:05 (were you got lucky) you will see the slot was very close in line with the insert so the insert could pop back in. Still, if I look at the inserts, they look ragged. A lot of damage at the front section where the coupling sleeve rides over it. It will work, but it won’t have that silky smooth action. Move like a “jam it in there” kind of feel. Do you plan on rebuilding it?

-

Transmission internals question

Watching your video, its hard to tell what going on. Reverse can be a bit iffy when selecting it like that on a bench like that. I'm not sure if its something to worry about or just leave it and move on.

-

Tranny Speedo tooth gear housing swap - 280z 5 speed

I have never fitted a 4:11 or a 4:38 diff in a Zdd, but I think it's all in the way the adapter is fitted on the 20 and 21 teeth (red and purple) version. The adapters are offset and it could be just a simple case of spinning it 180 degrees. The adapter for the larger gears is the same as the smaller gears, but the locking tab slot is 180 degrees from the smaller gears version. That is when all other variables are the same. I have read, on another website, that you can use a "wide ratio" 5 speed adapter in a "close ratio" 5 speed when using the red or purple gears. This would confirm the offset issue since those two adapter are 180 degrees apart. You could try cutting the slot on the other side of the adapter, or pick up another one to suit the transmission. You are using a "wide ratio"? Any 280Z will do for a donor. How to identify - F5W71B Wide and Close ratio transmission.pdf

-

How do you get this off? Or does it come off?

Nissan calls it a side rod, but most people call them a tie rod end. The section that was under the ball joint is the steering arm. If you don't have a tie rod puller, you can use two large hammers or a large metal block and a hammer. Its generally easier to nog them apart with the steering arm still mounted, but with two hammers, one as a block to absorb the force, it should come apart easy.

-

Flow Rate and P/N Of Original Factory Injectors

A lot of the JECS I have seen have A46-00. The Bosch injectors that I have seen and use in my 280Z are 0 280 150 116. I did have an XLS file with the flow rate somewhere.

-

FS5W71B 280zx transmisson rebuild

I agree. I think 3rd gear needs replacing. I can't recall ever having seen one of these gears seperating (wobble) like that. The fact that you can press it "true" again without too much effort, doesn't seem right to me. Then again I have never had one wobble and need to try that.

-

FS5W71B 280zx transmisson rebuild

Hi Dave, Looking at the third gear rotating in the video. It's not good. Some not right with it and the noise is gone with it out, seems to indicate that 3rd gear is your culprit. Tip for mounting the front counter shaft gear. Put in in the oven for 30 minutes at 60°C. It will go on a lot easier. Works well with bearings too. General rule with press fit items is not to do it too often because they can loosen and loose there grip on the shaft.

-

FS5W71B 280zx transmisson rebuild

I listened to the noise in your video. It doesn't sound good at all. I can understand your concern about moving forward with this transmission. The wobble on the 3rd/4th synchro hub is not normal. That hub, and the 5th/reverse hub can be mounted the wrong direction, but that wouldn't create a wobble. Might be one of the springs out of place. Just curious, have you tried your turning test with it in 3rd or 4th gear? If that hub is causing your problem, I would expect you should notice some kind of difference in noise. You are going about it the right way, if thats any comfort. Doing one thing at a time will help identify the cause. Better than stripping the tranny down and trying to identify what was making the noise.

-

FS5W71B 280zx transmisson rebuild

It will be goed to hear it on video. Im having trouble imagining what it could be.

-

FS5W71B 280zx transmisson rebuild

I had a collegue on the phone and did'nt see you reply. It could be a piece of grit in a bearing, but I would expect it to be gone by now. A bent shaft, not saying it can't happen, but generally you see something else like chunks of metal in the gears to create such a large sidewards force on the shaft. The gears should show signs of this, like chipped or gouged teeth. Can you feel it when its ticking?