Everything posted by EuroDat

-

Zx 5 speed rebuild

Hi Charles. Not sure what you mean by this, but if it's the cluster shaft bearing or cluster shaft it should be in its most rear position when you use the Plastigauge to check clearance.

-

Zx 5 speed rebuild

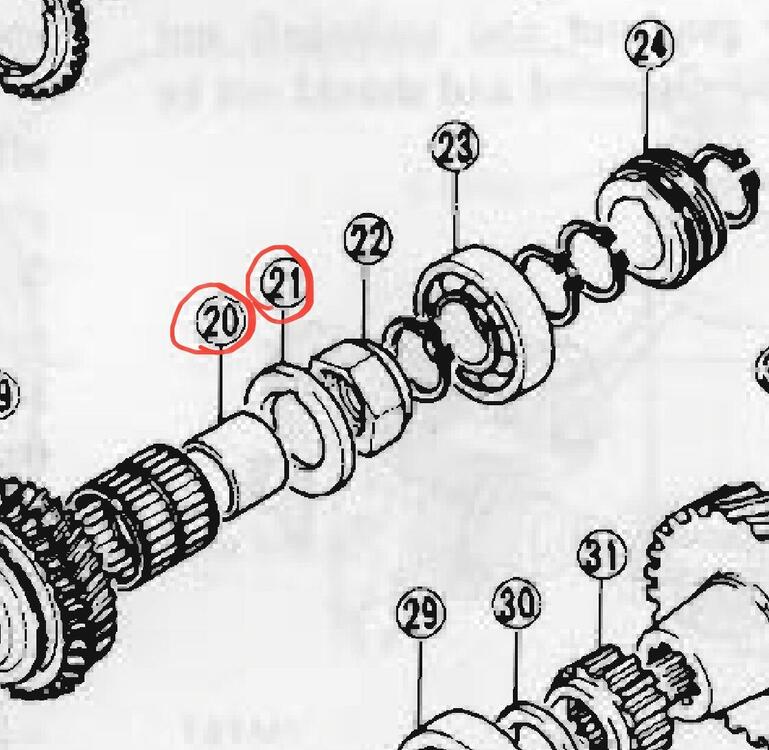

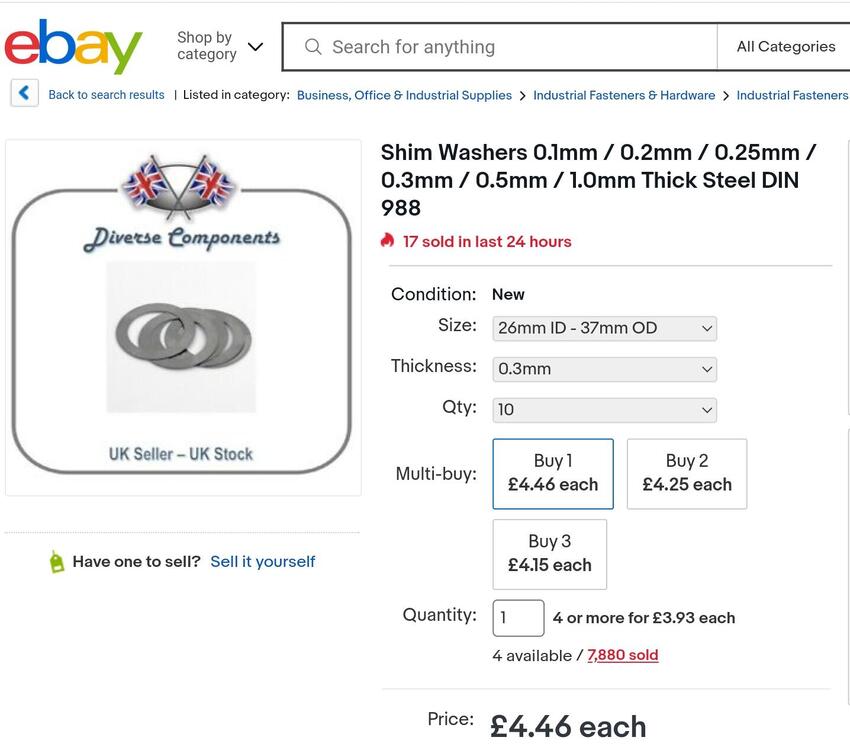

The fifth gear clearance can be corrdcted by adding shim stock between the washer (pos 21) and overdrive gear bushing (pos 20). Shim stock thickness 0.01 (0.25mm) is easy to cut with tin cutters. You could try to find shim washers the right size. Google "shim washers din 988". Go for the right inner diameter if you can't find one with the right dimensions. Trimming the outer diameter is easier than the inner diameter.

-

Zx 5 speed rebuild

I just checked my plastigauge stock and the brand Plastigauge would be green (PL-C) for the clearance 0.175 to 0.5mm. It is easy to use. Just break off a couple of short 15mm lengths and place them on the bearing. Place the plastigauge on one of the cage humps across to the outer race. You can hold it in place with a dab of play-doe on the cage section. Bolt on the front cover with gasket to the correct torque. Open it up gentle and don't twist the cover. The section of plastagauge over the outer race will be flatter than the rest. Use the gauge setting on the packet to determine clearance. Plenty of videos on youtube. If you can't find any plastagauge, PM me.

-

Zx 5 speed rebuild

Easiest way to gain the right clearance on the rear gear is to add a shim between the large washer (in your photo you are holding it with your finger and thumb). If you buy the thin brass shim stock you can cut a washer with a good pair of scissors. Add the shim stock to the gear side of the washer to add clearance. When I'm home I will take some photos of what I mean with Plastagauge and how to use it on the bearing.

-

Zx 5 speed rebuild

The front bearing shim is important for distributing the axial forces over the two cluster shaft bearings. No shim and the bearing in the adapter plate has to carry all the forces and waer faster. You can determine the shim thickness using plastagauge. I thick the yellow (0,2 to 0,4) would be best choice I think. The clearance on 5th gear is very tight and will probably cause lubricating issues

-

Shifter Rattle

It's in the right way. It wont fit the other way. The other end where the selector rod passes through colides with 3rd and 4th when you fit the fork on backwards. If you feel comfortable wiring the forks it shouldn't do any harm. I take it you want to wire them because you're worried they might fall out or work their way out. They shouln't fall out that easy. I have only ever seen two 71B with them double pinned like @Zed Head said. One was for a rally car and the other was unknown.

-

Existing FS5W71B Bearing/Seal Size Inventory?

None of the original bearings were sealed. If you source aftermarket o-rings and seals, make sure they are NBR or viton (FKM / FPM).

-

Existing FS5W71B Bearing/Seal Size Inventory?

@Zed Head Hi ZH, It is in the Tech Articles, but what you say is true. I find it difficult to find stuff in the Resource section.

-

Shifter Rattle

0.25 is OK. You will not have any problems with that clearance if you use a good quality oil like MT-90.

-

Shifter Rattle

When you say "the end play goes super tight and out of spec...." you mean no clearance at all? It is good to read you are checking clearances. Some people don't and it can destroy what could have otherwise been a very good rebuild. No clearance: That is not good at all. You need clearance between the gear and end washer to lubricate the needle bearing and end faces of the gear or the gear will litterally weld itself to the washer, hub and damage the needle bearings beyond use. The problem is without enough clearance the needle bearing starves of oil and overheats. The gear will then expand faster than the other components and create more friction/heat. The extra friction will weld it to the washer or hub, trust me.

-

4 Speed Bell Housing swap to 5 Speed Case : FS5W71B : Reverse Switch Modification

Some extra info on the rear bushing. Nissan did not sell a replacement rear bushing for the Zed and early 720 truck transmissions. If it was worn you needed a new rear extension housing. The correct (alternative) rear bushing for the wide and close ratio zed transmissions is the Omega Machine & Tool P/N: 71411. The NIS-62 (SKU: 303066) fits FS5W71C transmissions for 4 cyl models 200SX 84-88, 240SX 2.4L 88-97, 720 84-86 etc, but not the zed transmissions

-

1971 HLS30-14938 "Lily" build

Well Charles, you can tick that off the list. A very but tick at that indeed. The end job looks great. Must feel fantastic seeing it finally paint after all the issues earlier this year.

-

280z - 1977 upgrade brake to 4 calipers Toyota 4Runner

My only advice on upgrading is choose wisely. This original brake set-up, although primative, worked well. In its time it was regarded as a good set-up. Building your own system and taking a couple of runs up and down the local supermarket parking lot doesn't add up to the R&D that went into this set-up. Power booster and MC is not the issue here. They only determine the force needed and brake pedal travel. The biggest issue I have is getting the balance between the front and rear set-up. I often read threads where people have made their own combination and having trouble with balance. A lot of aftermarket setups available out there, but it would pay to research them and read what others have experienced before taking the plunge. My system is standard with Porterfield pads and shoes. I just visited their website and wow they certainly are pricey these days. Mine have less than 20k km so they will last for a while yet. I was thinking of upgrading to slotted/drilled discs when I need to replace the pads. The garage that does the roadworthy test commented on the brake test. You don't see that very much on these old cars. @Patcon Understandable in your country, but I live in a "flat as a pancake" country called The Netherlands. Smelling brakes in a street car is not on my bucket list. My only hill climbs are the highway overpasses

-

280z - 1977 upgrade brake to 4 calipers Toyota 4Runner

If you want better brakes. The standard setup properly rebuild with Porterfield R4-S pads and shoes will work fine. I have been using them since 2014 and never had issues for street use. If it is for looks, then there are plenty of "upgrades" out there. Getting the front to rear balance right is the biggest challenge you will have to deal with. I have no experience in racing zeds.

-

Best transmission fluid!?

AC Delco or GM transmission fluid comes highly recommended for these transmissions. The part numbers are AC Delco USA p/n: 88900399 or GM USA p/n: 12377916 That or the Redline MT-90 (75W-90)

-

Scarab Parts Car (Craiglist)

If it is a Scarab, then it is most probably some "do it selfer" bought a kit or partial kit and installed some of the items. From what I have heard about Scarabs, they can be ordered as a kit where you could build it yourself or you could have Scarab modify your car. Scarab wasn't mass producing these cars, but they were "custom" made to order and the customer could select mods to suit their our desires. I can remember seeing a post with an ad where you could order a V8 kit from Scarab for a Ford or Chevy V8 iirc and you supplied the engine. That would leave it open to all kinds of engine configurations. If that is the case, it would be near impossible the difine a Scarab as a particular model and option pack. And a "real" Scarab would only be valid with the original documents stating the options the S30 received. This one seems to be missing some of the basic scarab details like Scarab engine rocker covers, rear spoiler en the emblems. What it does have is the typical V8 fitted against the firewall and the 6 flutes (Scarab had none, 6 or 15) in the hood. If someone wants to do a V8 swap, it would make a great parts car.

-

Part numbers and cross filing of parts and their ID ?

If it's the 280Z, you can use the bosch L-Jetronic. Google Bosch relay 0 332 514 120

-

280Z 5Speed transmission noise (with video)

Hi Johnny, I sent you a PM😁 Listening to your video again. I'm fairly certain it's a centre bearing.

-

Parts Wanted: Looking for a standard 280zx flat top piston

True. I didn't mention any combinations outside the states. Europe didn't get the N47 head. They stayed with the N42 until the P79 came. The N47 was a legacy of the emmision rules in California. Basically a N42 with round emmision exhaust ports and steal valve seats for lead free fuel. Both the N42 and N47 had 44.6 cc chambers. The P79 and P90 both have 53.6cc chambers. The P79 was fitted to a NA engine with flat top pistons. The P90 and the P90A (version with hydraulic lifters) were used in combination with dished pistons in the turbo engines. The dished pistons are 10.9cc The P79 with flat top pistons has a CR 8.5:1 The P90(A) with dished pistons has a CR 7.35:1 An interesting combination was to change the P79 head to a N47. Everything else unchanged would give you a CR 9.75:1. None of this is helping the OP. He still needs a flat top piston out of an engine that used the P79 head. BTW "Stamped P79 on top." Is refering to the head. The block will be a N42 or F54 in combination with the P79 head. Everything else has dished pistons.

-

Parts Wanted: Looking for a standard 280zx flat top piston

The 280Z had the N42 block all with dished pistons The 280ZX had a couple of block/head combinations 79-80 had the N42 block with dished pistons and the N47 head. 8.3:1 compression ratio. 81-83 had the F54 block with flat top pistons and the P79 head. 8.8:1 compression ratio. ZX turbo had the F54 block with dished pistons and the P90 or in 83 the P90A head. You need a piston out of the F54/P79 combination.

-

Shifter Rattle

1. It's not easy to test the condition of the bearings and gears with the transmission dismantled like that. It might be a bad bearing causing the hard spots. 2. The shafts tend to wobble around when they are free. The bearings have a clearance specification of C3. You will always see some side ways movement over a shaft more than a foot long and even more with worn bearings. While you dismantle the adapter plate check the bearings are clamped in place by the retainer plate. There should be no end play. 3. The nut should be tight. Loose is not good. To tighten the nut I bought a 38mm tube socket and welded an extra length tube on it and a 1/2" drive socket on it. Worked well.

-

Shifter Rattle

Yes, you MUST remove the circlip. The input shaft will not come off with the bellhousing because the input shaft spur gear (gear teeth for the 3rd/4th hub) is larger than the gear and hits the front cluster shaft gear. Once you remove the bellhousing, you can remove the front cluster shaft bearing and gear with a puller and some heat and then the input shaft will come free.

-

3-4 & 5Th Shift Inserts aka "Dogs" For 1983 Datsun 280ZX transmission aka Insert-Shifting, Overdrive

Just posting a sceenshot of your PM message. It's good to post the result for others. Good or bad. Nice to hear it worked out.

-

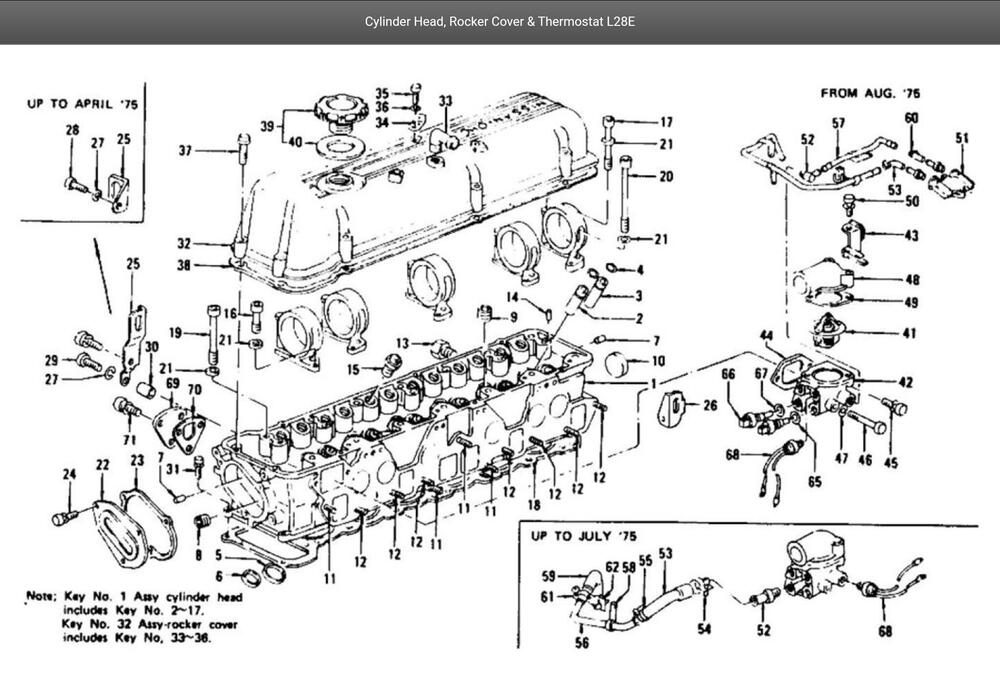

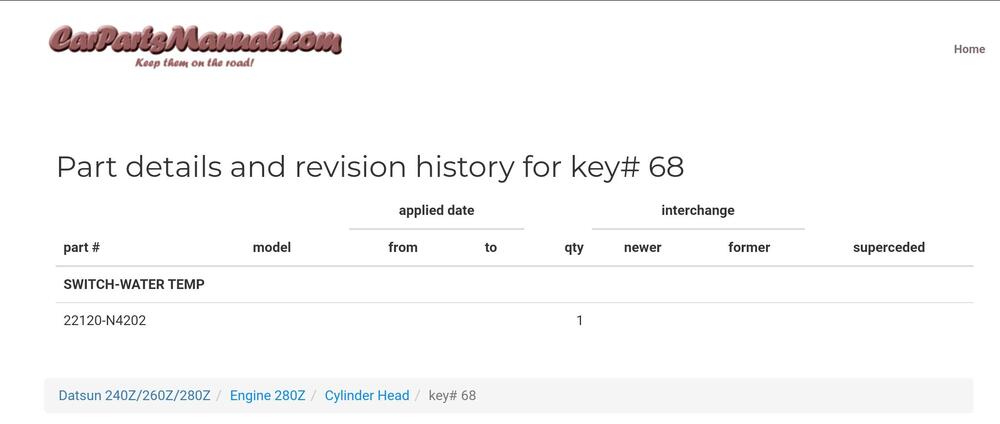

L28 sensors

Thanks to Zed Heads work I found it in the carpartsmanual - cylinder head section, but little info about what it does. Thanks for the EGR info Dave👌. I was looking towards ZX, but should have been looking the other direction.

-

L28 sensors

I agree. I have seen it mentioned as a thermo switch for the airco in other threads, but I can't find anything about it in the AC wiring diagram. My 280Z has factory air and doesn't have the switch. Maybe @ennisdavis can tell us which L28 he is refering to. Could be something ZX....